Wall plate splicing structure

A wallboard and pressing board technology, which is applied in the direction of building components, building structures, covering/lining, etc., can solve the problems of insufficient connection of adjacent wallboards, affecting the quality of wallboards, and overall collapse of wallboards, achieving simple structure, Not easy to enter the water, the effect of firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

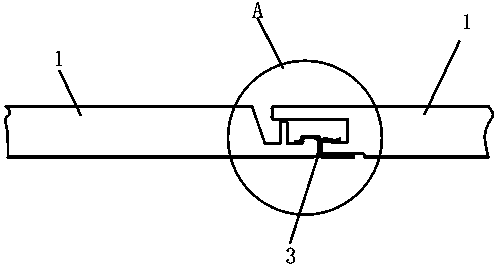

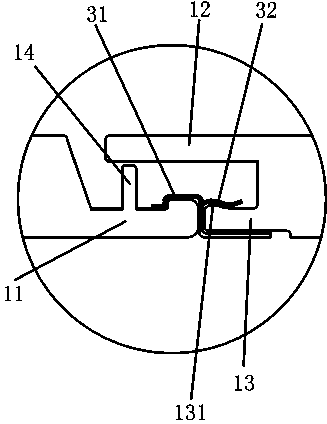

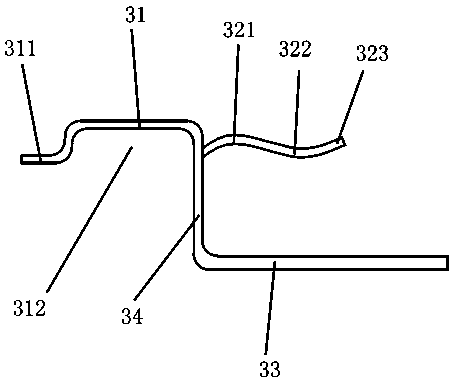

[0035] A wallboard splicing structure, comprising a number of wallboards spliced with each other, the wallboard includes a board body 1 and a connecting part 1 and a connecting part 2 arranged on both sides of the board body, the connecting part 1 and the connecting part 2 between adjacent wall boards The second connecting part is connected by a clamping connector 3, the clamping connector 3 is a metal plate, and the clamping connector 3 includes a pressure plate 31 and a pressure plate 31 formed by folding the upper staggered sections of the metal plate to the opposite direction. The second pressing plate 32 and the mounting plate 33 for fixing to the wall are formed by folding the lower part of the metal plate toward the pressing plate 2 32, and the mounting hole 35 is arranged on the mounting plate. The middle part of the metal plate is a splint 34 arranged vertically. The first connection part includes a connection plate 11 that is formed by extending outward from the low...

Embodiment 2

[0041] The difference from the above embodiments is that the water baffle 14 is an arc-shaped plate. The length of the clamping connector is 3 cm, the first pressing plate 31 is three pieces, and the second pressing plate is two pieces.

[0042] When installing, put the lower wallboard on the wall first, and snap the lower end of the wallboard into the clamping groove, then snap the upper end of the wallboard into the back slot of the clip, and fix the clip-on connector on the wall with screws. After the wallboard is fixed, a wallboard is placed above it, and the lower end of the wallboard is snapped into the clamping slot of the clamping connector, so that all the wallboards are installed in sequence. The present invention ensures the firmness of the installation of the wallboard through the fastening of multiple parts of the wallboard and the clamping connector, the wallboard is not easy to collapse, the use is safer, the wallboard has good water resistance and long service ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com