Turnover slip

A flip-up, slip technology, used in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problems of outer circle wear of the pipe string, and achieve the effect of reducing the number, expanding the scope of application and improving the safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

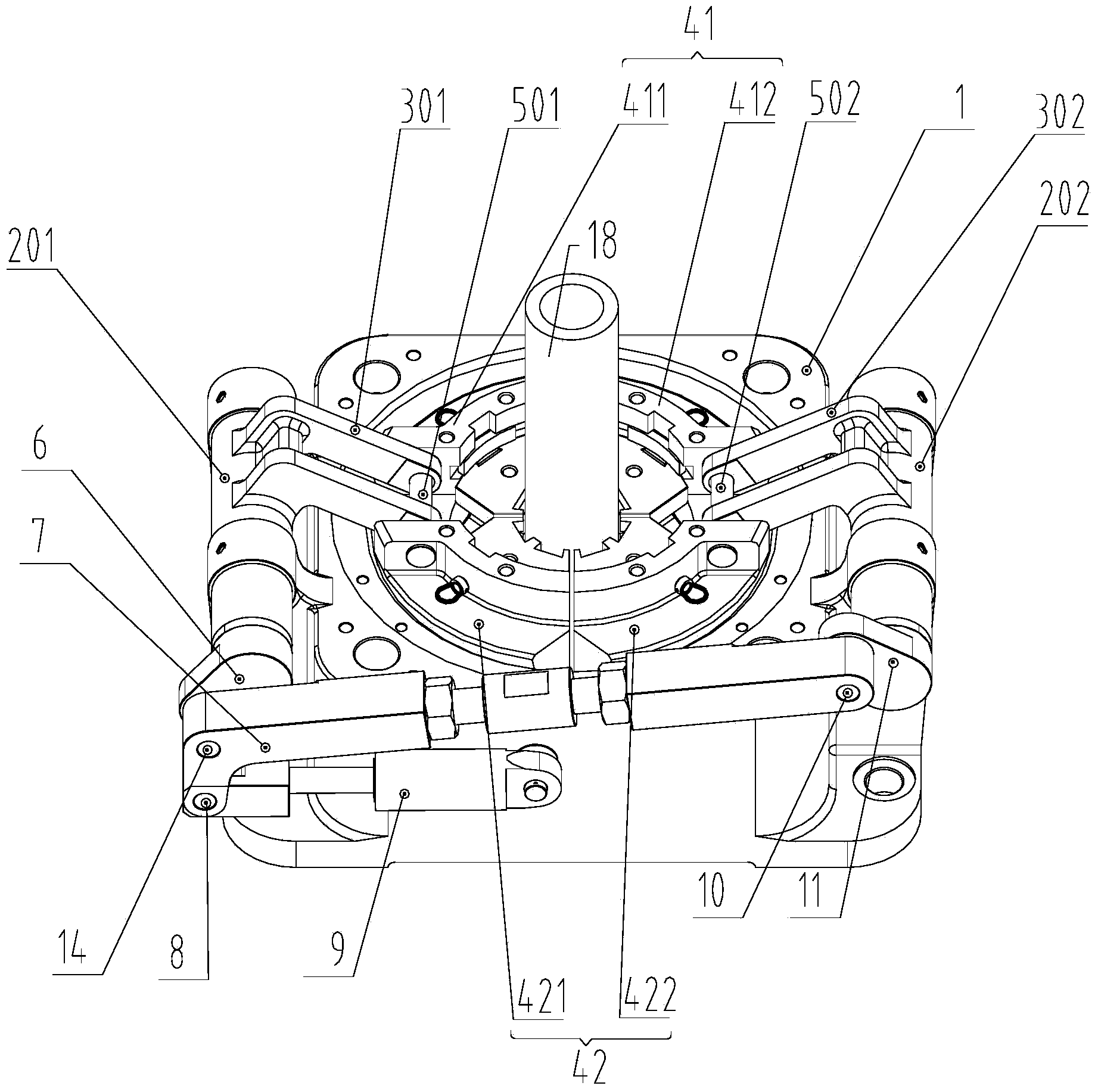

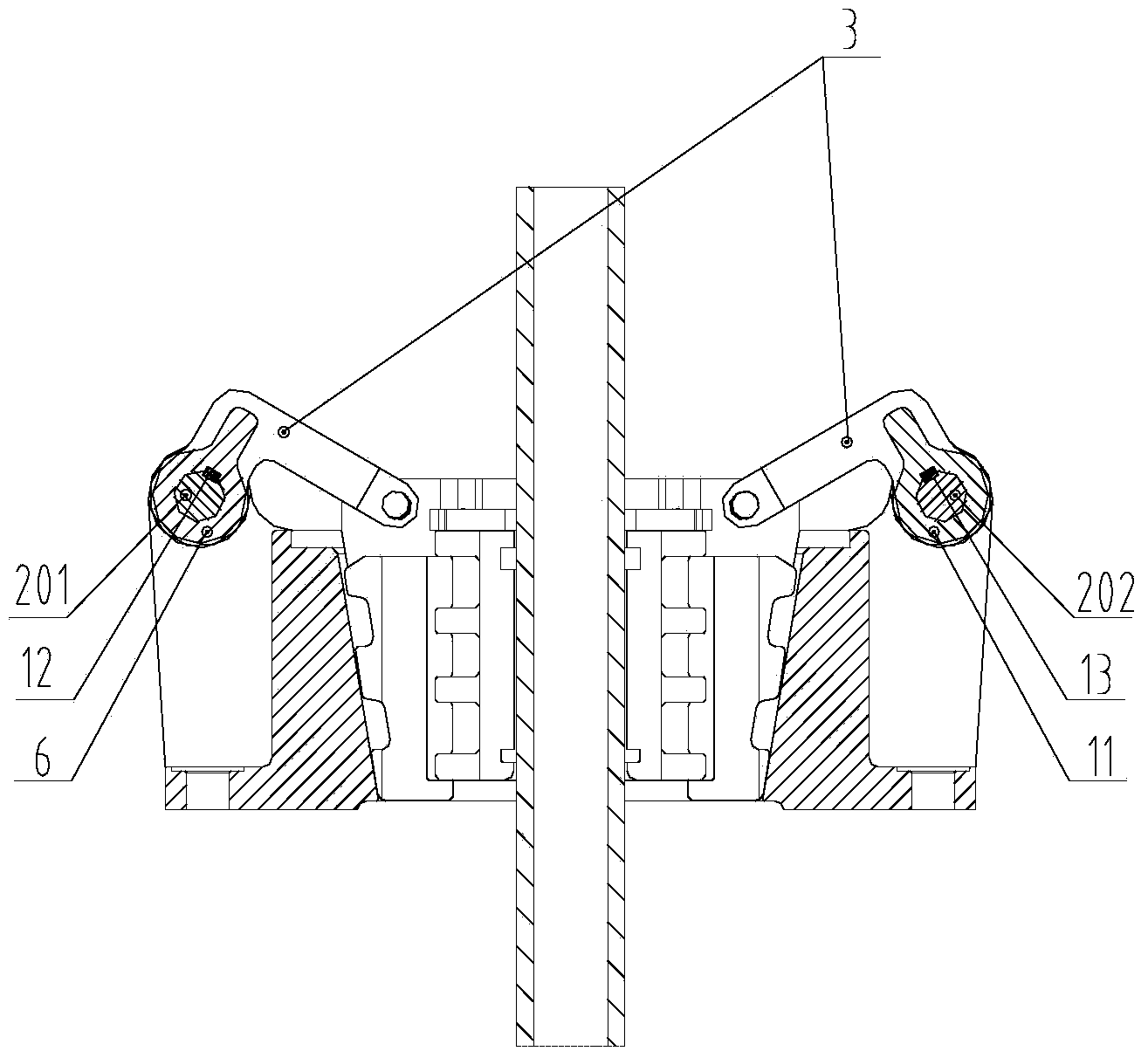

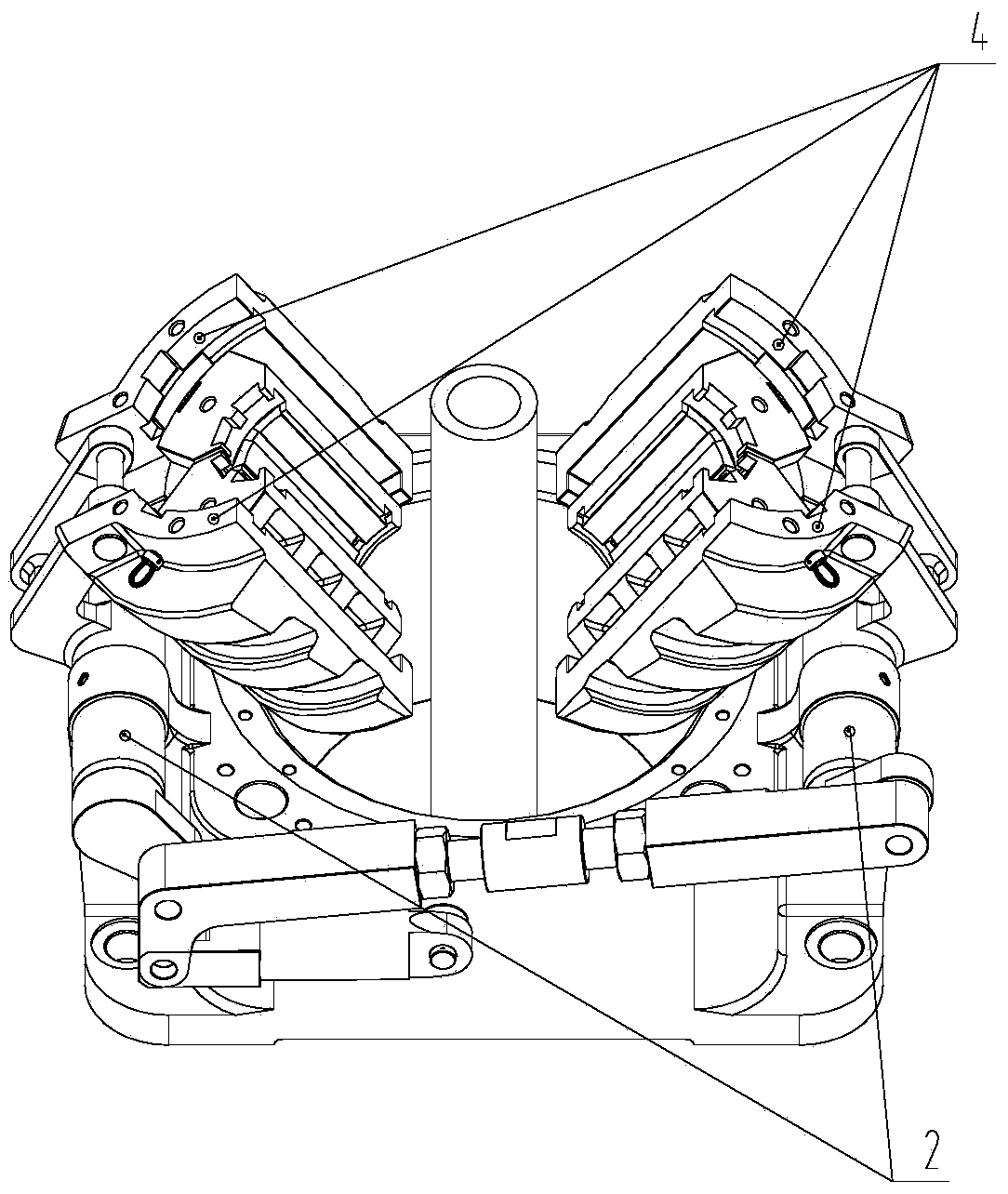

[0041] Such as Figure 1 to Figure 4 As shown, a flip-type slip includes a slip seat 1, and a connecting shaft 2 is hinged on the slip seat 1. The connecting shaft 2 includes a first connecting shaft 201 and a second connecting shaft 202; the first connecting shaft 201 and the second connecting shaft The two connecting shafts 202 are respectively located on both sides of the slip seat 1 .

[0042] A rocker arm 3 is installed on the connecting shaft 2 . The rocker arm 3 comprises a first rocker arm 301 and a second rocker arm 302. One end of the first rocker arm 301 is fixed on the first connecting shaft 201, and the other end of the first rocker arm 301 is a movable end. The first rocker arm 301 can be As the first connecting shaft 201 rotates around the axis of the first connecting shaft 201; one end of the second rocking arm 302 is fixed on the second connecting shaft 202, the other end of the second rocking arm 302 is a movable end, and the second rocking arm 302 can rota...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap