Compressor stability expanding system and compressor mechanism applied to same

A compressor and casing technology, applied in the field of compressors, can solve the problems of reduced performance of the compressor, limited expansion of the stable working conditions of the compressor, and small degree of internal flow of the compressor, so as to improve the internal flow and expand the stable range. The effect of widening and widening the stable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

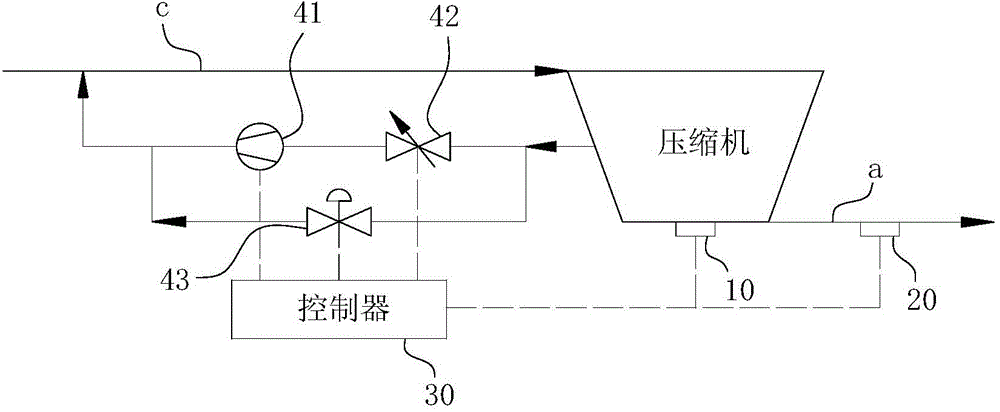

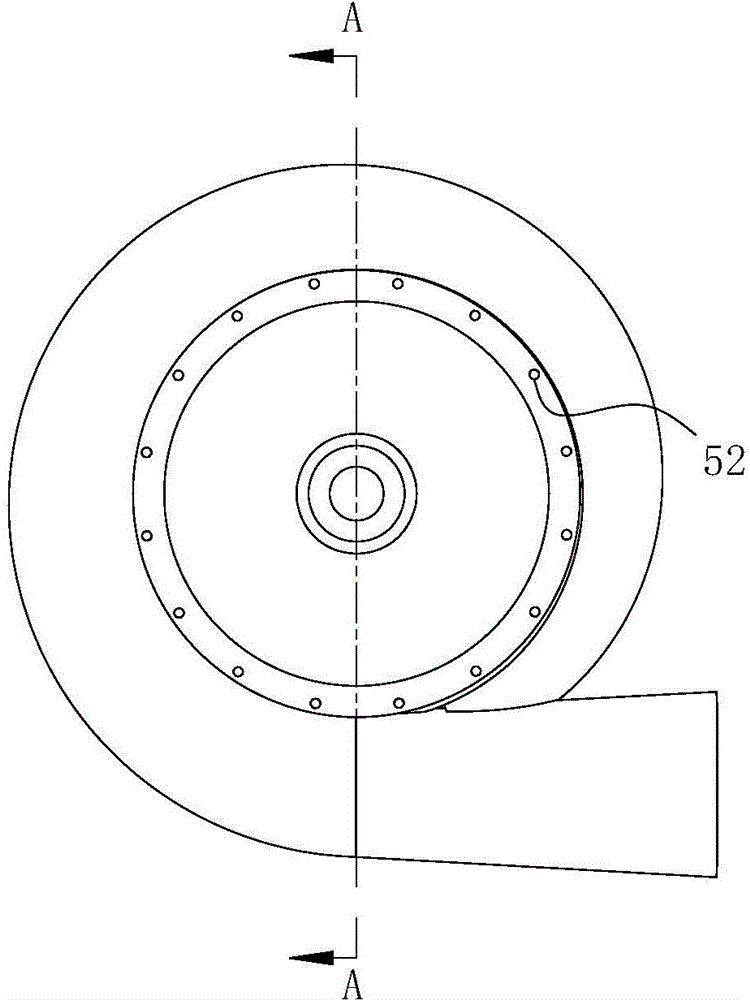

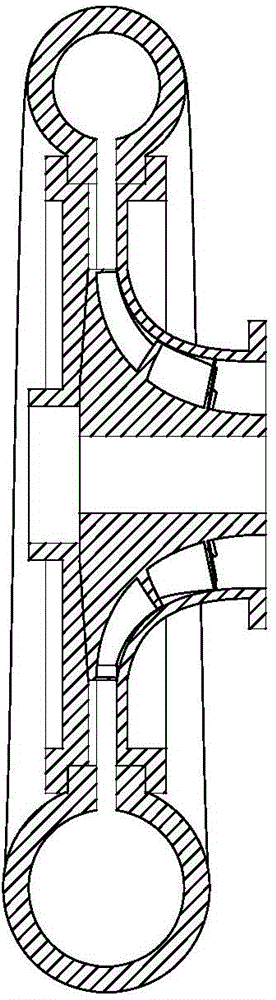

[0025] combine here Figure 1-5 Concrete structure and workflow of the present invention are described as follows:

[0026] For ease of understanding, the following definition is made here for the "inner arc surface of the compressor casing cover plate b": the inner arc surface of the compressor casing cover plate b is located at the half-open impeller of the compressor impeller cavity, and at the same time This position is also the turning point of the gas in its impeller, for details, please refer to Figure 4-5 shown.

[0027] Figure 2-3 It is a structural schematic diagram of the compressor used in the present invention, which specifically includes centrifugal compressor components such as a semi-open impeller, a compressor casing cover b, a machine cover and a diffuser, and the present invention is applicable to Figure 2-3 The single-stage centrifugal compressor shown is also applicable to a multi-stage centrifugal compressor based on the principles of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com