A method for preparing highly stable arsenic-fixed minerals by hydrothermal method

A high stability, hydrothermal technology, applied in the field of mineral arsenic fixation, to achieve the effect of wide stable area, low equipment requirements, and small BET specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

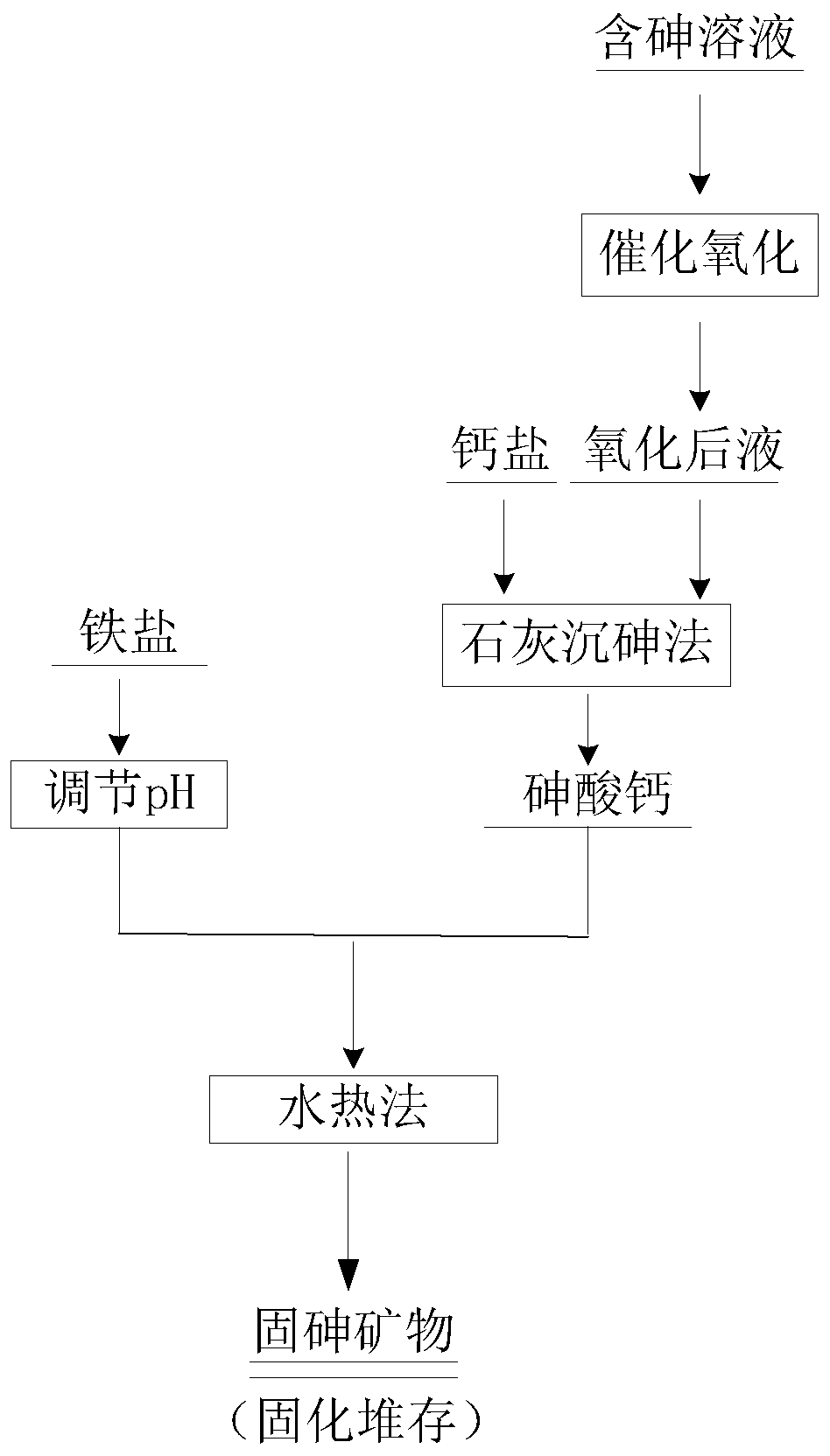

Method used

Image

Examples

Embodiment 1

[0037] The main components in the arsenic-containing solution include: As 60g / L, Sb 1.1g / L, Pb 235ppm, Sn 38.5ppm, Te24.4ppm, NaOH 30g / L.

[0038] A method for preparing high-stability solid arsenic minerals includes the following steps: the arsenic-containing solution adopts a catalytic oxidation method to 3+ Oxidized to As 5+ , The control condition is that the oxygen flow rate is 5L / min, adding KMnO 4 For the catalyst, the As / Mn molar ratio is controlled at 10:1, and the temperature of the catalytic oxidation system is controlled at 90℃. The results show that As 3+ The conversion rate is 98.45%.

[0039] Adjust the pH value of the oxidized liquid to 1.5, and add CaO and Ca(OH) by continuous feeding 2 As an arsenic precipitation agent, the molar ratio of Ca / As is 5, the settling time is 6 hours, and the reaction temperature is 60°C to generate calcium arsenate. The synthesis of arsenic-fixed minerals adopts the hydrothermal method, and the control condition is that the calcium ars...

Embodiment 2

[0041] The main components in the arsenic solution include: As 76g / L, Sb 0.8g / L, Pb 96.7ppm, Sn 27.5ppm, Te38.7ppm, NaOH 25g / L.

[0042] A method for preparing high-stability solid arsenic minerals includes the following steps: the arsenic-containing solution adopts a method of catalytic oxidation to remove As 3+ Oxidized to As 5+ , The control condition is that the oxygen flow rate is 10L / min, adding KMnO 4 For the catalyst, the As / Mn molar ratio was controlled at 40:1, and the temperature of the catalytic oxidation system was controlled at 30℃. The results showed that As 3+ The conversion rate is 92.31%;

[0043] Adjust the pH value of the oxidized liquid to 2, add CaO and Ca(OH) in a continuous feeding manner 2 As an arsenic precipitant, the molar ratio of Ca / As is 8, the settling time is 8 hours, and the reaction temperature is 90°C to generate calcium arsenate. The synthesis of solid arsenic minerals adopts the hydrothermal method, and the control condition is that calcium arse...

Embodiment 3

[0045] The main components in the arsenic solution include: As 50g / L, Sb 1.8g / L, Pb 186ppm, Sn 34.7ppm, Te27.8ppm, NaOH 5g / L.

[0046] A method for preparing high-stability solid arsenic minerals includes the following steps: the arsenic-containing solution adopts a method of catalytic oxidation to remove As 3+ Oxidized to As 5+ , The control condition is that the oxygen flow rate is 1L / min, adding KMnO 4 For the catalyst, the As / Mn molar ratio is controlled at 20:1, and the temperature of the catalytic oxidation system is controlled at 120℃. The results show that As 3+ The conversion rate is 89.36%

[0047] Adjust the pH value of the oxidized liquid to 1.5, and add CaO and Ca(OH) by continuous feeding 2 As an arsenic precipitation agent, the molar ratio of Ca / As is 5, the settling time is 10 hours, and the reaction temperature is 60°C to generate calcium arsenate. The synthesis of solid arsenic minerals adopts the hydrothermal method, and the control condition is that the calcium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com