Vacuum release valve for tank truck loading and unloading

A vacuum release valve, oil tanker technology, applied in valve details, safety valve, balance valve and other directions, can solve the problems of increased maintenance costs, damaged tanker valve body, insensitive work, etc., to reduce maintenance costs, reduce Labor intensity, the effect of avoiding deformation and damage to the valve body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

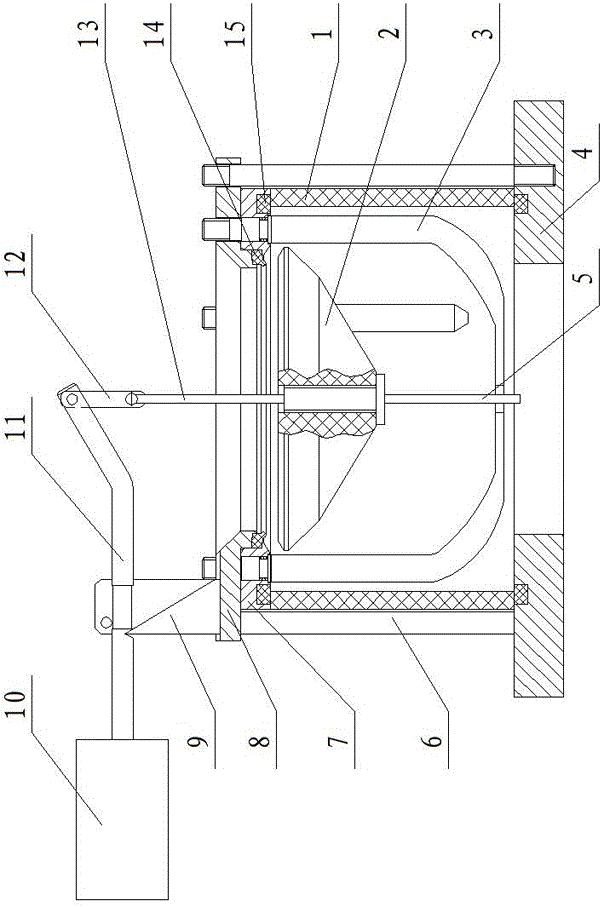

[0010] A vacuum release valve for loading and unloading an oil tanker, comprising a valve body 1, the bottom of the valve body 1 is provided with a butt joint flange 4 fixedly connected to the tank mouth connection flange of the oil tanker, and at the center of the butt flange 4 is a There is an air inlet connected to the tank mouth of the tanker, a cover is provided on the top of the valve body, an air supply port corresponding to the air inlet is opened in the center of the cover body, and a sealed air supply port is provided inside the valve body The valve clack 2 used is provided with a guide frame 3 between the internal valve clack 2 of the valve body 1 and the valve body 1, the top of the guide frame 3 is fixedly connected with the cover body, and the center of the bottom of the valve clack 2 is set downward. There is a guide rod 5, a guide hole passing through the guide rod 5 is provided at the bottom of the guide frame 3, a connecting rod 13 protruding from the air supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com