Electric switching device for sample valve for chromatography

An electric switching and sampling valve technology, applied in valve device, valve operation/release device, measuring device, etc., can solve the problem of slow switching speed, manual switching of gas path can not be automatically controlled, cylinder-driven switching gas path switching angle cannot be Adjustment and other issues to achieve the effect of strong applicability, precise rotation control, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0016] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 The layout method is described, such as: the positional relationship of top, bottom, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0017] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

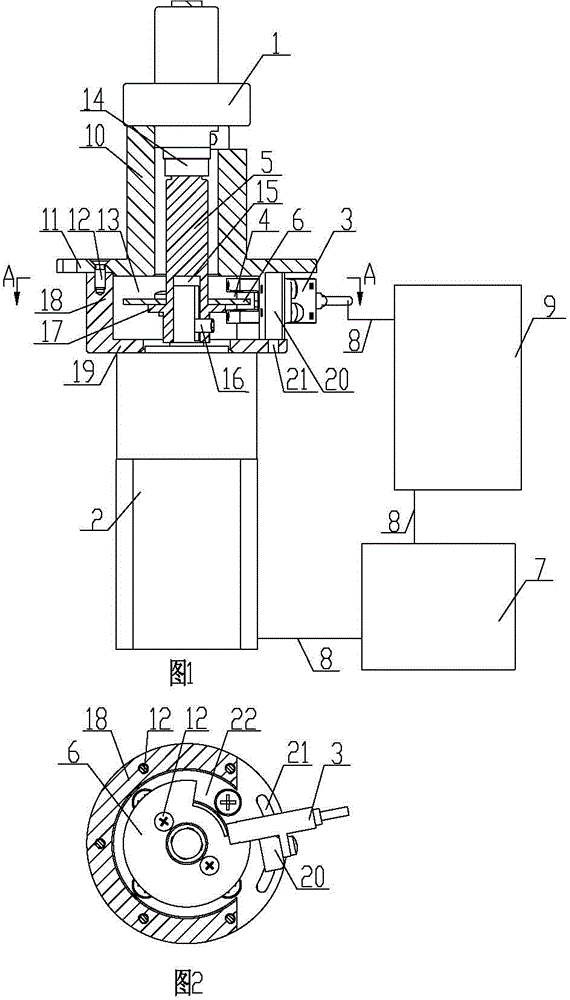

[0018] as attached figure 1 , 2 As shown, the electronic switching device for the injection valve for chromatography includes a mounting base, an injection valve for chromatography 1, a stepper motor 2, a photoelectric switch 3, a rotating shaft 5, a light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com