Binocular photogrammetry method of large flexible structure vibration displacement

A technology of flexible structure and vibration displacement, which is applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, and interpretation of photos, etc. It can solve problems such as the influence of flexible structures on performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

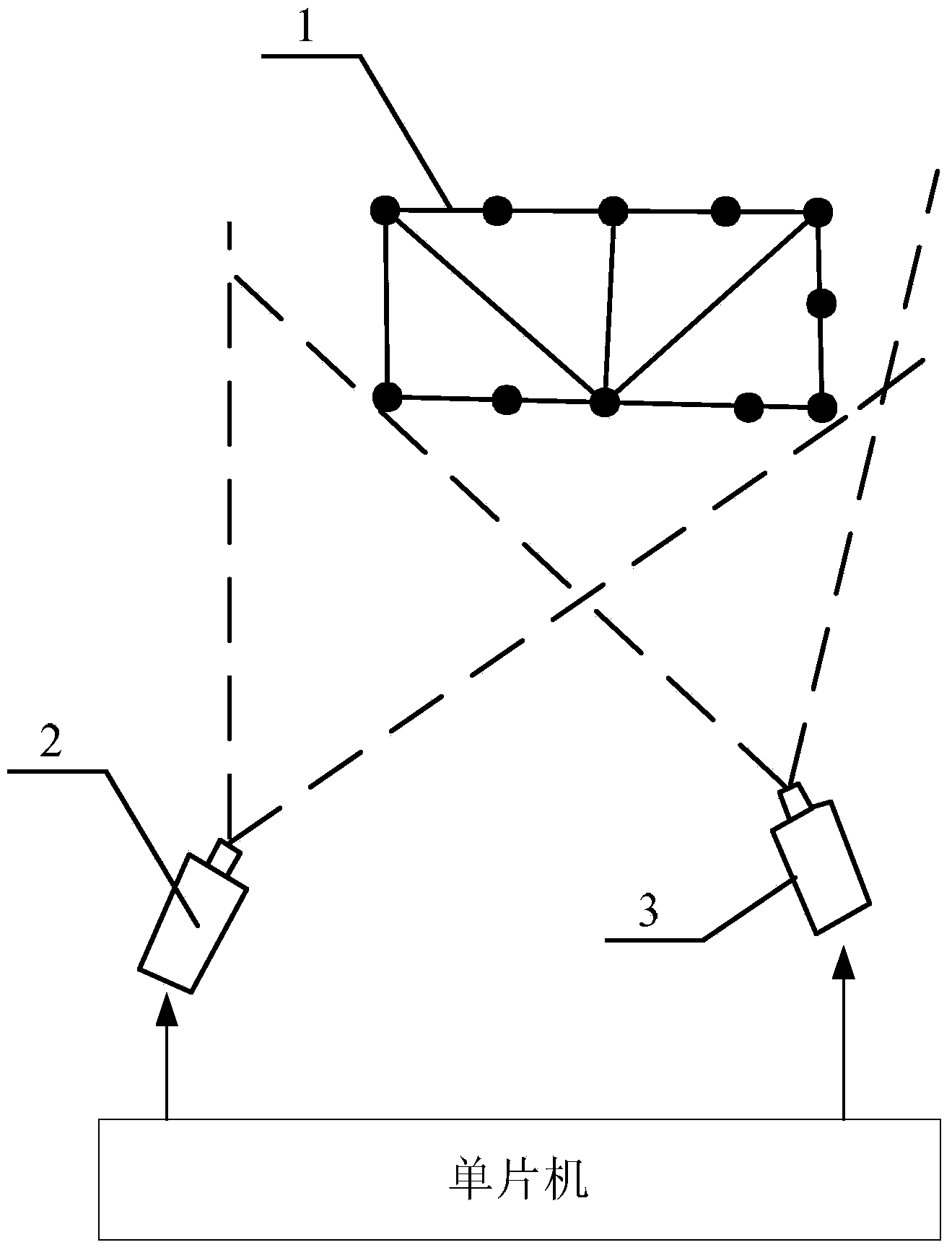

[0039] Specific implementation mode one: the following combination Figure 1 to Figure 3 Describe this embodiment, the binocular photogrammetry method of vibration displacement of large flexible structure described in this embodiment, it comprises the following steps:

[0040] Step 1: Calibrate the industrial camera, the number of the industrial camera is 2-5;

[0041]Step 2: Excite the flexible structure under test, and at the same time, control all industrial cameras to trigger synchronously through the single-chip microcomputer, and shoot the vibration displacement of the measured point of the flexible structure under test;

[0042] Step 3: Process the images captured by all industrial cameras, use the corner detection algorithm to obtain the pixel coordinates of the measuring point, and then use the binocular 3D reconstruction technology to obtain the object space coordinates of the measuring point at each moment, so as to obtain the measured flexible The vibration displa...

specific Embodiment approach 2

[0044] Specific implementation mode two: the following combination figure 1 This embodiment will be described. This embodiment will further explain Embodiment 1. The specific method for calibrating an industrial camera in this embodiment is:

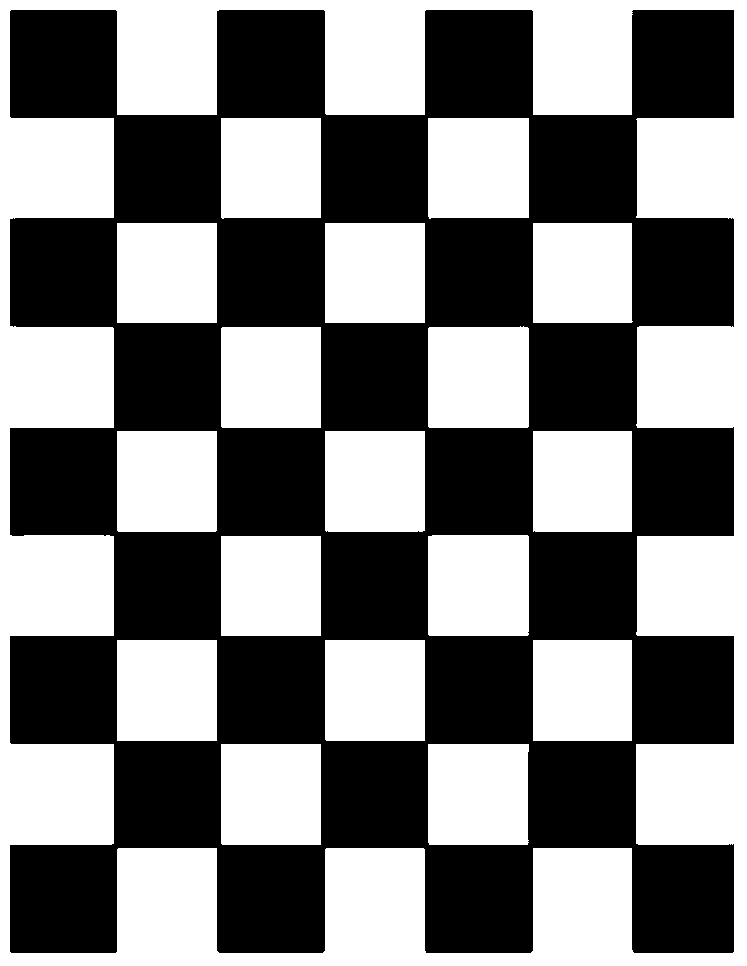

[0045] The calibration board is used to calibrate the industrial camera. The calibration board is a 7×9 checkerboard consisting of black and white squares, and the side length of the square is 5mm; the position of the calibration board is set so that the field of view of each industrial camera covers Complete the calibration board, and take a still image of the calibration board with an industrial camera to complete the calibration.

[0046] The calibration plate in this embodiment is printed with a high-precision printer to ensure that the calibration accuracy of the industrial camera meets the measurement requirements. After the calibration is completed, the installation position and angle of the industrial camera and the focal length...

specific Embodiment approach 3

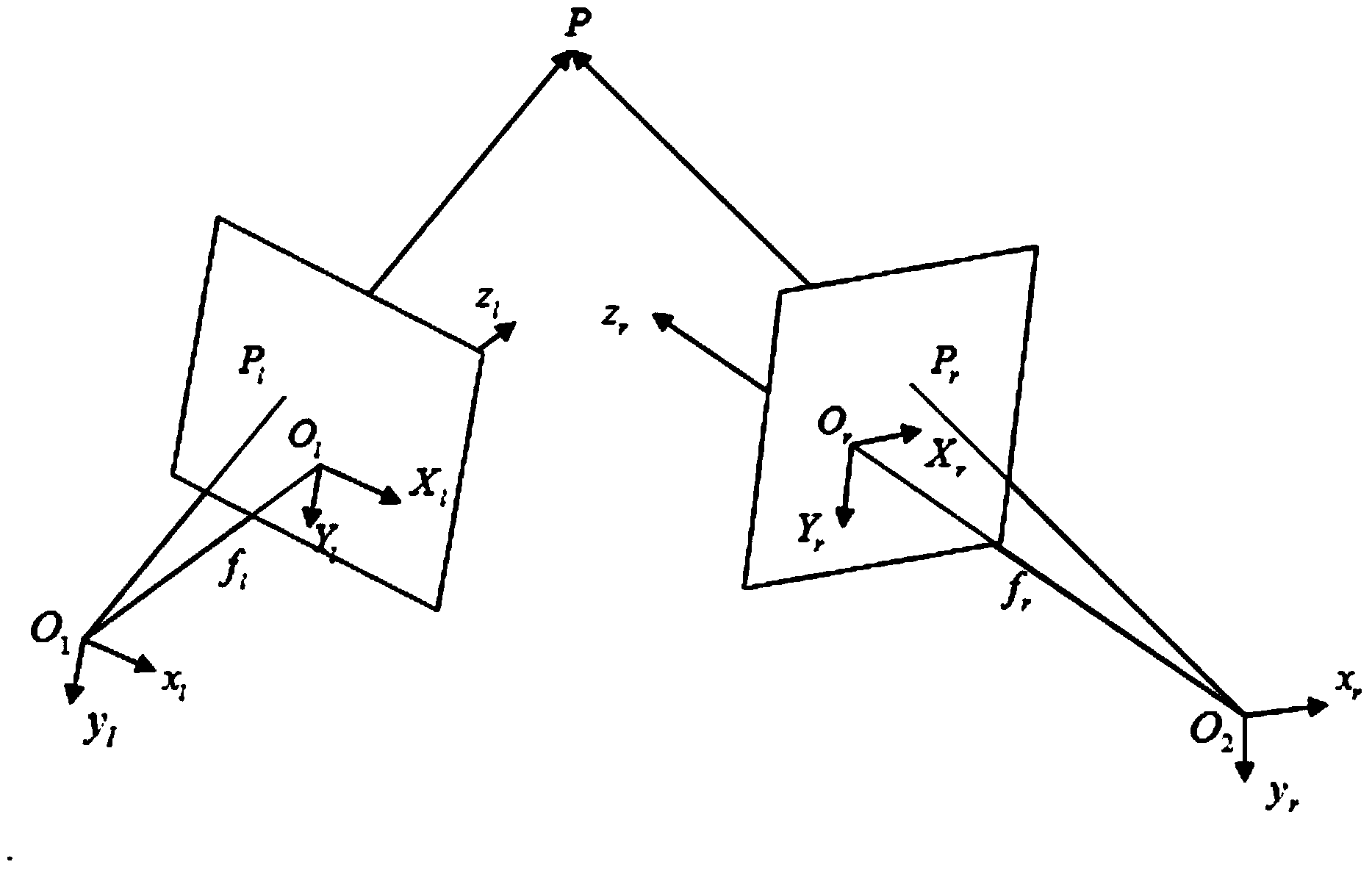

[0048] Specific implementation mode three: the following combination figure 2 and image 3 Describe this embodiment, this embodiment will further explain Embodiment 2, the number of industrial cameras described in this embodiment is 2, the specific method of obtaining the vibration displacement curve of the flexible structure under test in step 3 is:

[0049] The measured points of the flexible structure to be tested are photographed by two industrial cameras at the same time. After processing the captured images, the equations are established as follows:

[0050] Z c 1 u 1 v 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com