Method for calibrating effective spatial resolution of optical surface profilometer

A technology of optical surface and effective space, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of high requirements and expensive calibration modules, and achieve the effect of high accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

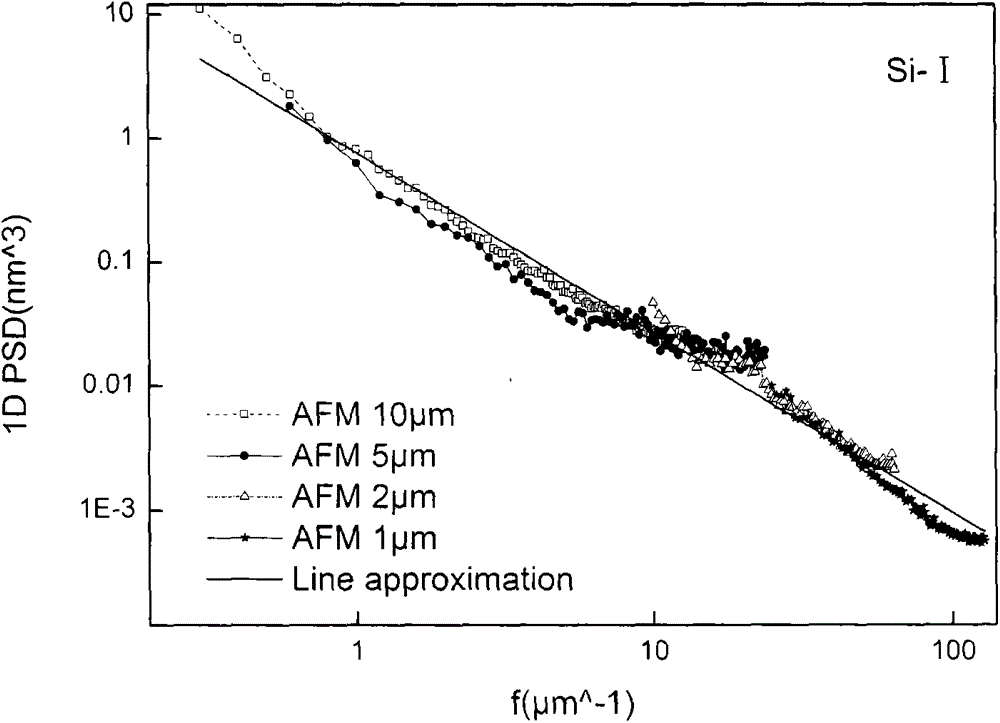

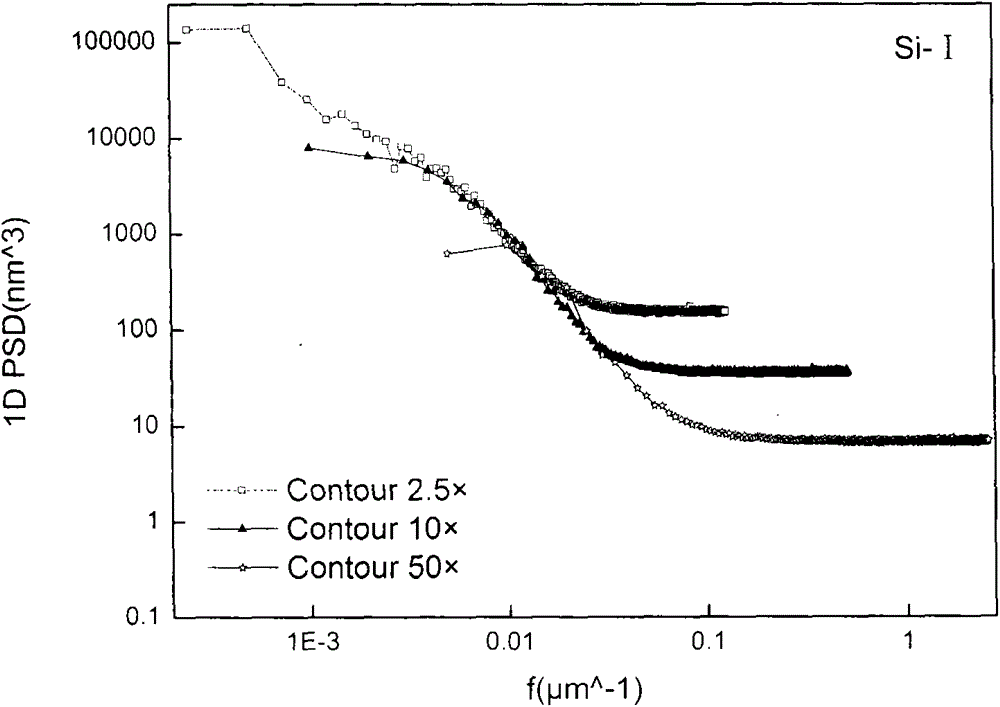

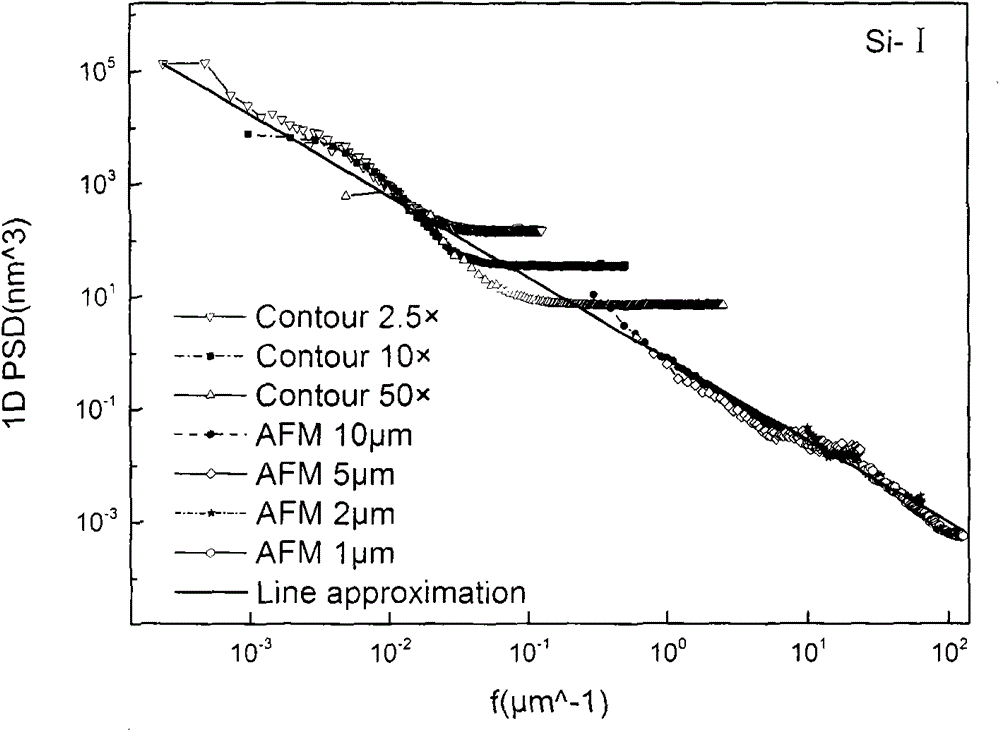

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples. The calibration sample selected in this example is a Si sheet with a thickness of 1 mm, denoted as Si-I. The selected calibration equipment is Veeco's atomic force microscope (MultiMode SPM), and the test areas for Si wafers are 10 μm × 10 μm, 5 μm × 5 μm, 2 μm × 2 μm and 1 μm × 1 μm. figure 1 The test results of one-dimensional power spectral density (PSD) in logarithmic coordinates are given in , and the power spectral density (PSD) curves of the four regions are almost on a straight line at the corresponding spatial frequency, which can prove that the Si chip Belongs to fractal surfaces. A straight line is fitted according to these four power spectral density (PSD) curves, and the equation of the straight line is y=-1.449x-0.119. According to the nature of the fractal surface, the power spectral density (PSD) curve of logarithmic coordinates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com