Troubleshooting method of engine in-position cross test

An engine and motive technology, applied in the field of aero-engine troubleshooting, can solve problems such as high cost, affecting the normal use of the engine, and long troubleshooting cycle, and achieve the effect of rapid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

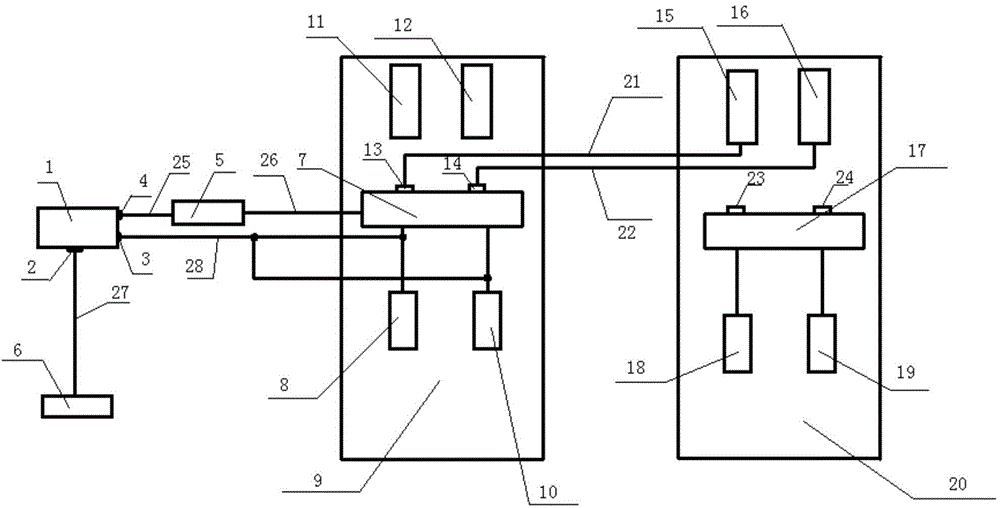

[0030] Specific embodiment 1: the test cable part a21 is the connection cable connecting the first side engine temperature control amplifier to the fuel flow regulator socket 13 and the second side engine fuel flow regulator 15; the test cable part b22 is to connect the first side of the aircraft The engine temperature control amplifier is connected to the anti-surge regulator socket 14 and the connecting cable of the engine anti-surge regulator 16 on the second side of the aircraft. For details, refer to image 3 .

[0031]

[0032]

specific Embodiment 2

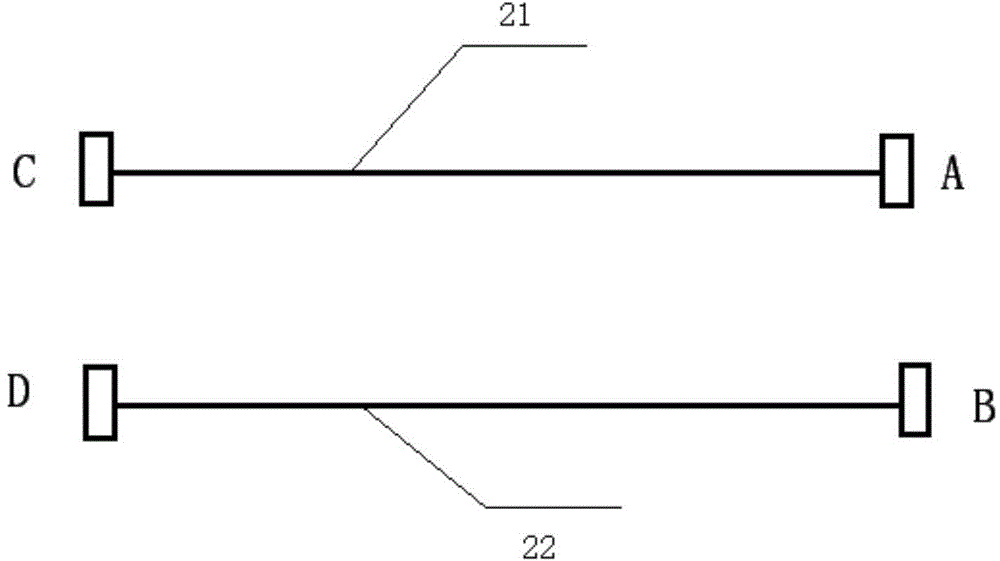

[0033] Specific embodiment 2: The middle parts of the test cable part a21 and the test cable part b22 of two cables are combined into one and made. Considering the distance between the two engines, the length of the cable is determined to be 1750mm, and the distance between the A-end, B-end, C-end and D-end is 250mm from the intersection. One end of the test cable is the fuel flow regulator and the anti-surge regulator. Corresponding interface, one end is the corresponding interface of the temperature control amplifier, please refer to Figure 4 .

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com