Charging roller capable of uniformly charging

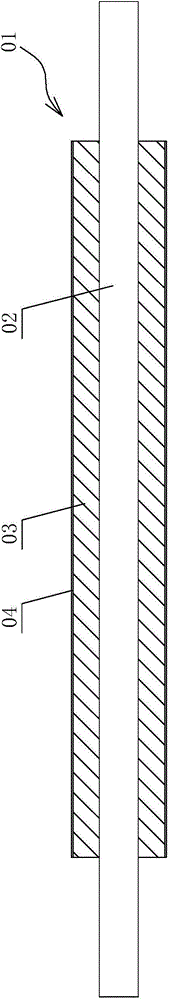

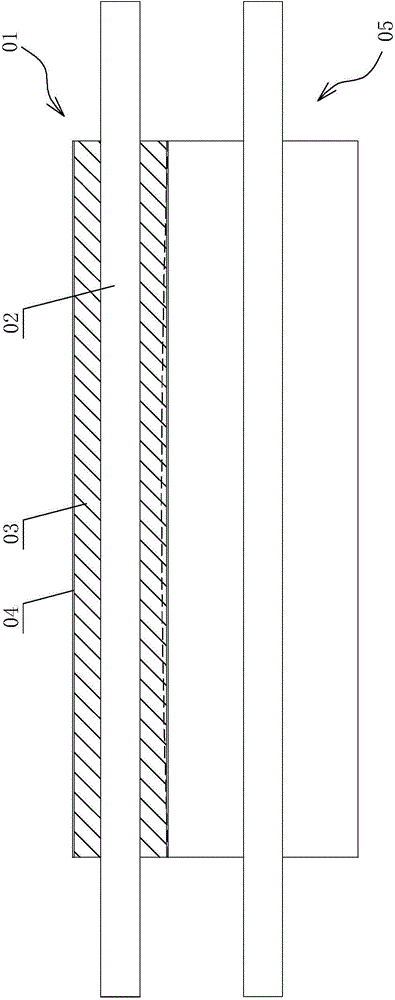

A charging roller and uniform technology, applied in the direction of corona discharge devices, circuits, electrical components, etc., can solve the problems of smaller diameter of sponge layer 03, poor periodic image, larger diameter of sponge layer 03, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

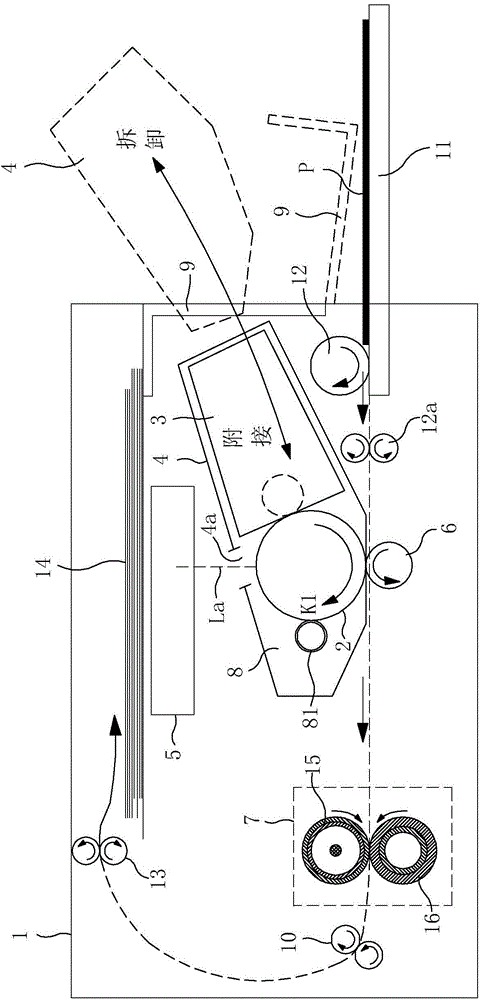

[0020] The best mode for carrying out the present invention will be described below with reference to the accompanying drawings.

[0021] image 3 is a schematic sectional view showing a schematic configuration of a laser beam printer (hereinafter simply referred to as "printer") 1 as an image forming apparatus according to this embodiment.

[0022] The printer 1 receives image information from an image information providing device (not shown) such as a host computer provided outside the printer 1. The printer 1 executes a process for recording images in sheet form based on the received image information through a known electrophotographic system. A series of image forming processes for forming an image on a recording material (recording medium) P.

[0023] The laser beam printer 1 includes a process cartridge 4 housing a drum-shaped rotatable electrophotographic photosensitive drum 2 serving as a latent image bearing member, a charging mechanism 8 and a developing device 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com