Flexible flat cable

A flat cable and flexible technology, applied in the field of flexible flat cables, can solve the problems of increased wiring difficulty, easy confusion, troublesome cable layout, etc., to reduce the risk of breaking, increase bending margin, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

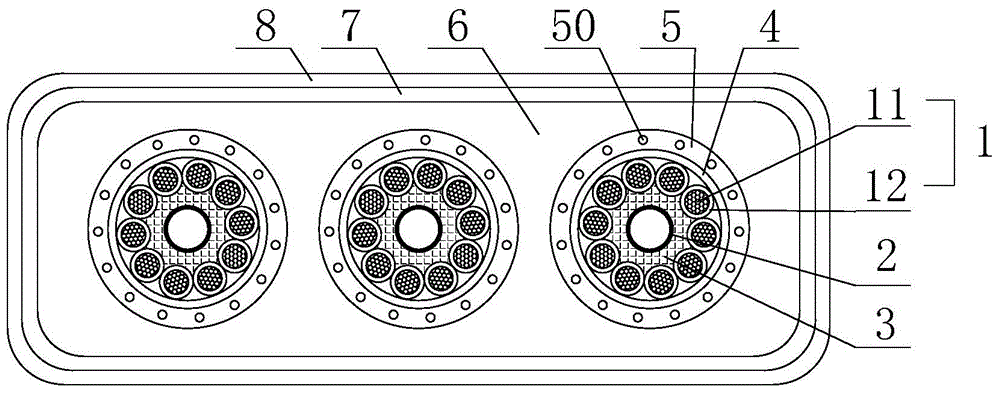

[0011] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a flexible flat cable proposed by the present invention.

[0012] refer to figure 1 , a flexible flat cable proposed by the present invention, including a plurality of core wires, a sheath layer 6, an adhesive layer 7, and a protective film 8;

[0013] Each core wire includes a wire core, an aluminum-plastic composite tape 4, and an elastic anti-extrusion layer 5; the wire core is composed of ten wires 1, aluminum metal hose 2, and aramid fiber 3, and the wire 1 includes a conductor in the middle 11. The conductor 11 is covered with an insulating layer 12; in the arrangement of the wires, ten wires 1 are arranged in a spiral shape around the aluminum metal hose 2, and the aramid fibers 3 are filled in the wires 1 and the aluminum metal hose. Between the tubes 2, the wire core is covered with an aluminum-plastic composite tape 4, and the aluminum-plastic composite tape 4 is covered with an ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com