Screw-connection-type diode for automobile generator

A technology for automotive generators and diodes, applied in the field of diodes, to achieve the effects of reducing failure modes, preventing falling off, and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

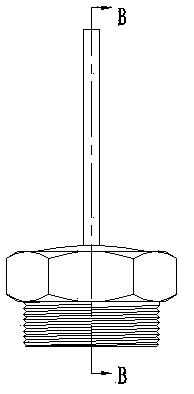

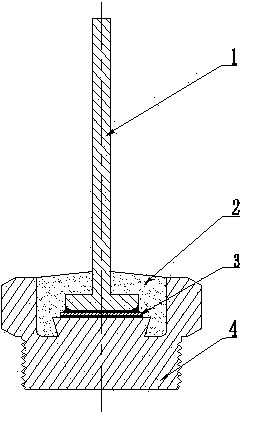

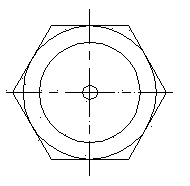

[0015] refer to figure 1 , figure 2 with image 3 Among them, the present invention consists of a base 4, a chip 3, a lead 1, and a sealant 2. A polygon is provided on half of the outer surface of the diode base 4, and a threaded structure is provided on the cylindrical surface of the lower half of the base 4. The diode passes through The threaded structure of the base 4 is connected with the cooling plate of the rectifier. The connection method described is a screw-in type. The polygon is a hexagon. The connection between the threaded structure and the heat sink of the rectifier can absorb expansion stress and relieve vibration through thread fit gaps.

[0016] The working process is as follows: when making the diode base 4, put the oxygen-free copper rod into the cold heading mold for upsetting and pressing to form a structure with a hexagonal upper part and a cylindrical lower part, and then use an automatic thread rolling machine to process the thread A complete bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com