Scintillator array, and X-ray detector and X-ray examination device using scintillator array

A scintillator array and scintillator technology, which are applied in the field of scintillator arrays and can solve problems such as reduced reflection efficiency of an adhesive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] As reflective particles, titanium oxide (TiO 2 )powder. Titanium oxide powder has a particle size distribution with a peak at 0.22 μm. The titanium oxide powder was mixed with an epoxy resin as a transparent resin after pulverizing aggregates with an ultrasonic vibrator. The mixing step of the titanium oxide powder and the epoxy resin was implemented using a three-roll mixer. The mixing time of the three roll mixer was set to 20 hours. The viscosity of the mixture (resin mixture) of titanium oxide powder and epoxy resin was set to 2 Pa·s.

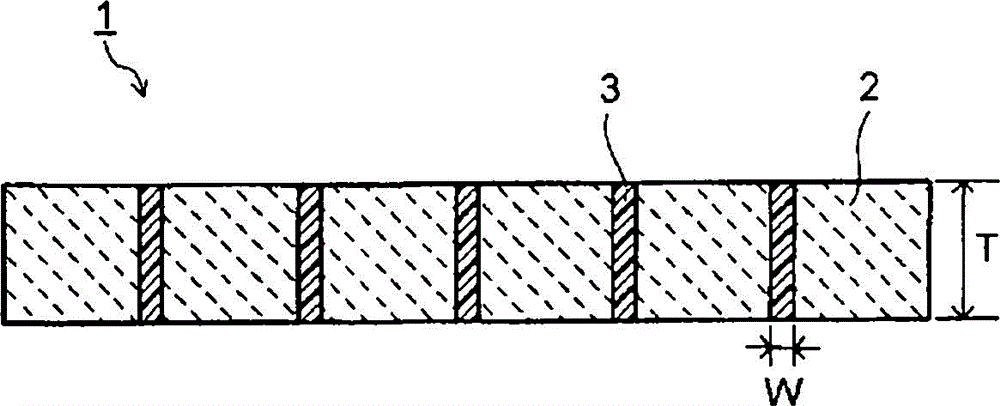

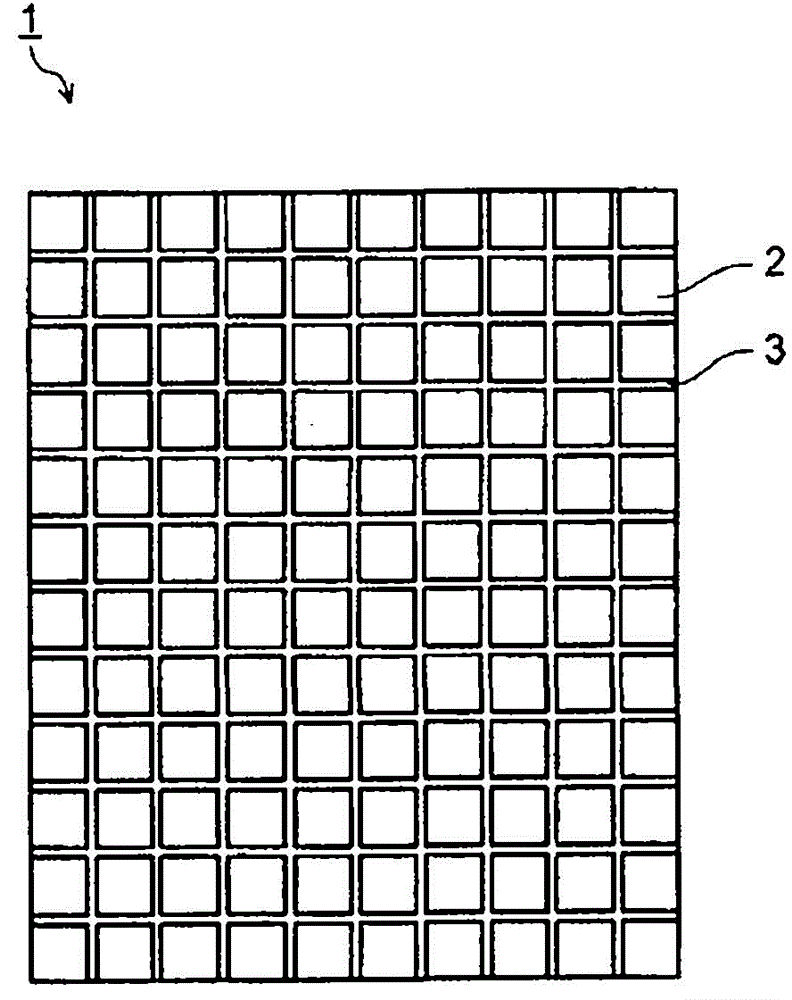

[0064] Next, gadolinium oxysulfide (Gd 2 o 2S: A scintillator module formed of a sintered body of Pr). The scintillator block was obtained by grinding|polishing so that the surface roughness (Ra) might become 1 micrometer. The interval between adjacent scintillator modules was uniformly set to 80 μm, and the scintillator modules were arranged so that there were 64 scintillator modules in the long side direction and 24 scintill...

Embodiment 2~5

[0066] A scintillator array was produced in the same manner as in Example 1, except that reflective particles having the average particle diameter and material shown in Table 1 were used.

Embodiment 6

[0083] As reflective particles, titanium oxide (TiO 2 )powder. Titanium oxide powder has a particle size distribution with a peak at 0.28 μm. The titanium oxide powder was mixed with an epoxy resin as a transparent resin after pulverizing aggregates with an ultrasonic vibrator. The mixing step of the titanium oxide powder and the epoxy resin was implemented using a three-roll mixer. The mixing time of the three roll mixer was set to 25 hours. The viscosity of the mixture (resin mixture) of titanium oxide powder and epoxy resin was set to 1.8 Pa·s.

[0084] Next, aluminum garnet ((Gd 0.49 Tb 0.20 Lu 0.30 Ce 0.01 ) 3 (Al 0.6 Ga 0.4 ) 5 o 12 ) The scintillator module formed by the sintered body. The scintillator block was obtained by grinding|polishing so that the surface roughness (Ra) might become 1 micrometer. The interval between adjacent scintillator modules was uniformly set to 80 μm, and the scintillator modules were arranged so that there were 64 scintillato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com