Solid-liquid separation device

A solid-liquid separation and solid technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve problems such as difficult separation, achieve the effect of improving stability, prolonging service life and improving separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

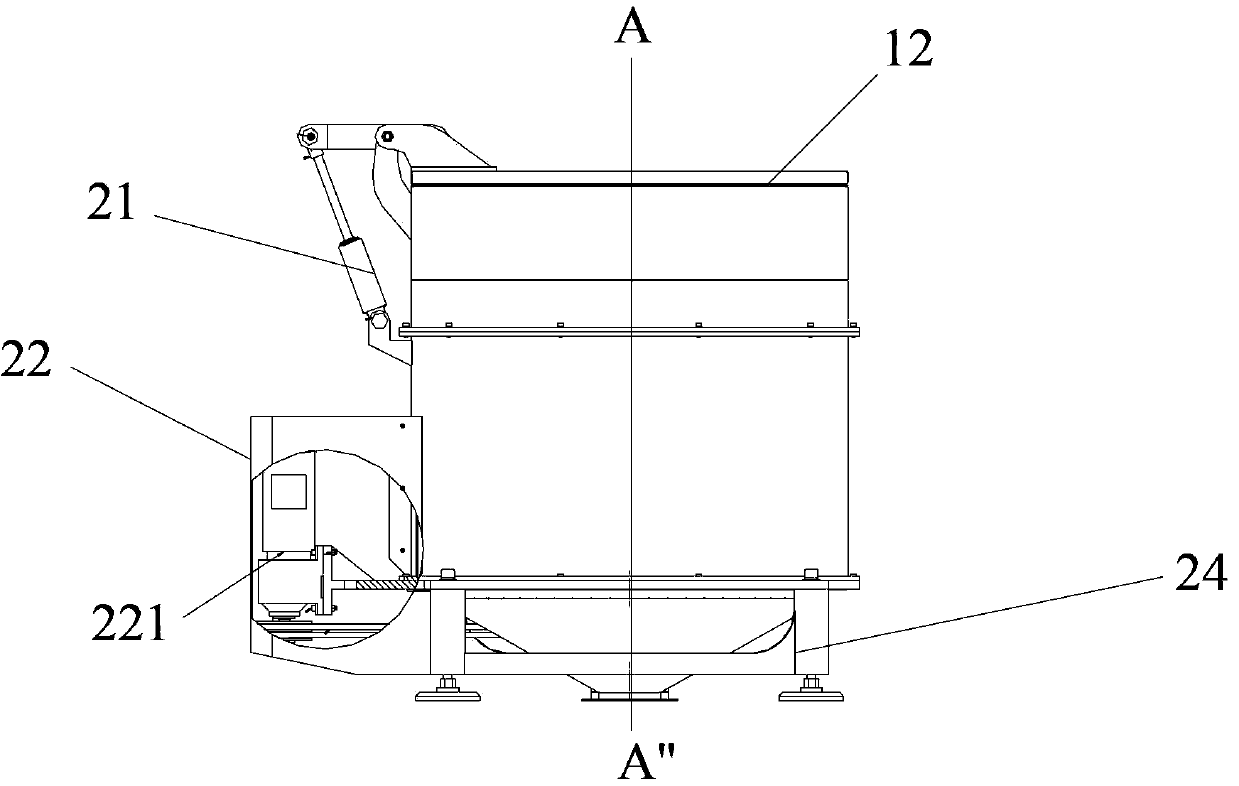

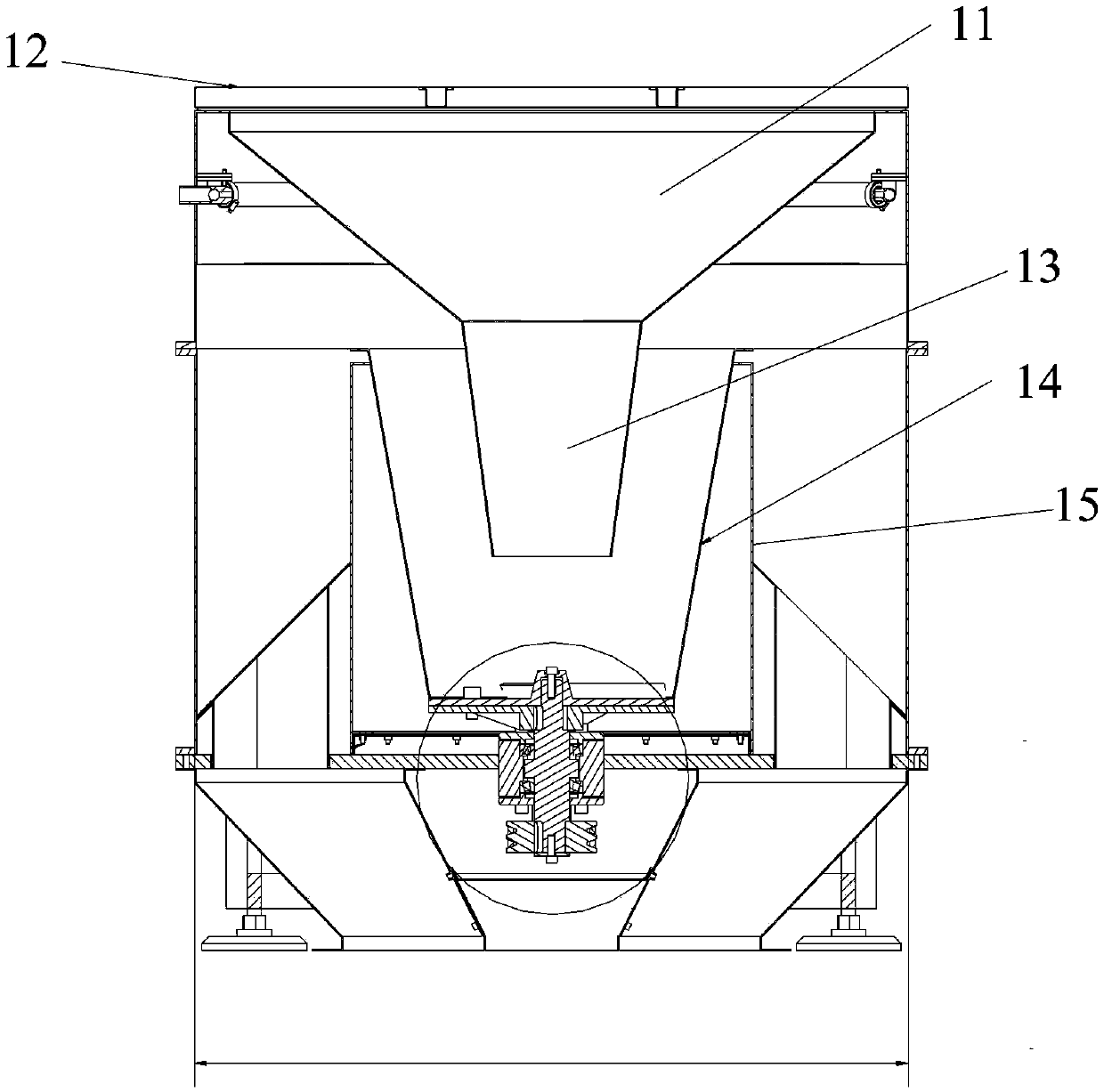

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. see figure 1 and figure 2 , the embodiment of the present invention provides a solid-liquid separation device, including: a housing 10, the upper part of the housing 10 is provided with a feed hopper 11, the top of the feed hopper 11 is provided with a cover 12, and the bottom of the feed hopper 11 has a tapered opening 13. A support structure 24 is provided at the bottom of the housing 10 .

[0026] A pull rod type opening device for opening the cover 12 is provided on the side wall of the housing, and the switch device is driven by a hydraulic or electric drive structure 21 .

[0027] The tapered opening 13 of the feed hopper 11 is arranged in the inner cylinder 14, and the tapered opening 13 of the feed hopper 11 has a larger distance from the bottom of the inner cylinder 14, which is convenient for the inner cylinder to accommodate the garbage to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap