A kind of low-temperature anti-fog method for glass

An anti-fog, low-temperature technology, applied in aircraft accessories and other directions, can solve problems such as affecting the driver's sight, and achieve the effect of preventing fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following structural examples describe technical solution of the present invention in further detail

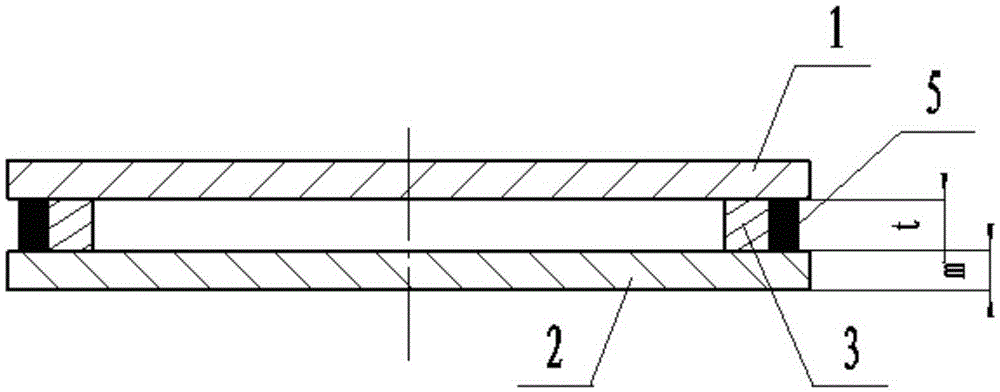

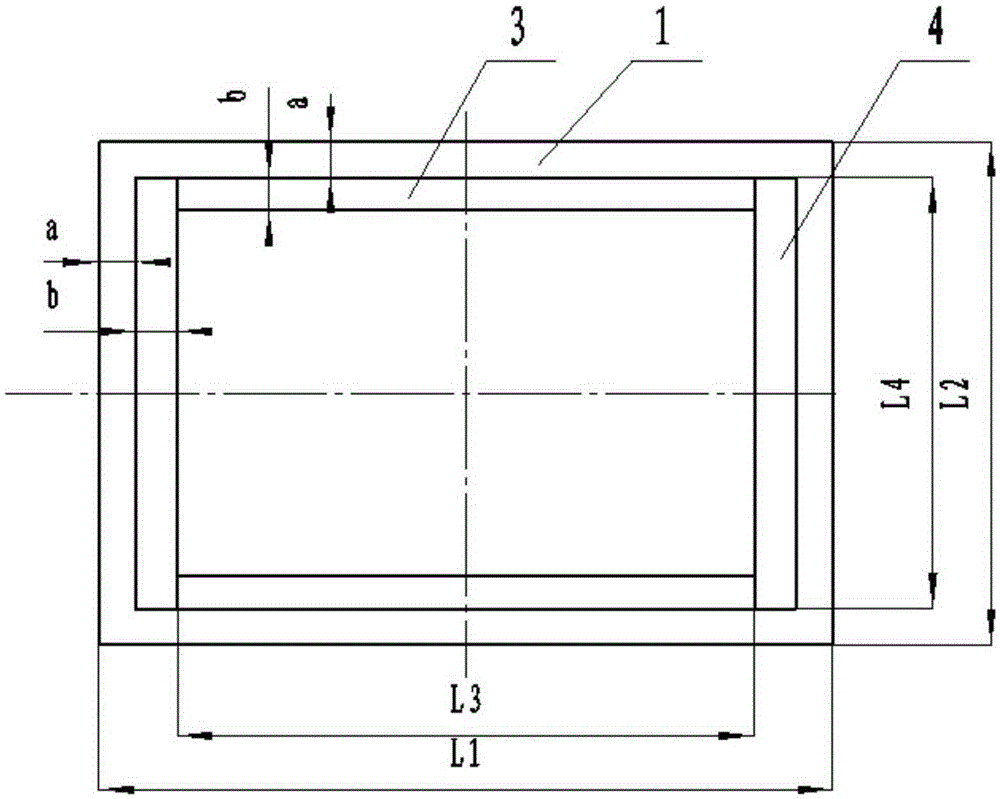

[0019] see figure 1 , 2 Shown, the step of this kind glass plate low-temperature anti-fog method is:

[0020] The first step, processing anti-fog glass plate

[0021] The thickness of the anti-fog glass plate 2 is m=2mm~4mm, the length L1 of the anti-fog glass plate 2 is equal to the length of the anti-fog glass plate 1, and the width L2 of the anti-fog glass plate 2 is equal to the width of the anti-fog glass plate 1;

[0022] The second step, paste the double-sided tape

[0023] The double-sided adhesive strip is composed of two long-side double-sided adhesive strips 3 and two wide-side double-sided adhesive strips 4. The thickness t of the side double-sided adhesive strip 3 and the wide-side double-sided adhesive strip 4 is 20 mm to 30 mm;

[0024] First bond two long-side double-sided adhesive tapes 3 to the long side of the anti-fog glass plate 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com