Carpet pyrography device

A technology for carpets and hot stamping heads, which is used in textile and papermaking, fabric surface trimming, thorn patterns, etc., can solve the problems of small three-dimensional amplitude and few patterns, achieve large concave amplitude, improve work efficiency, and shorten hot stamping operations. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

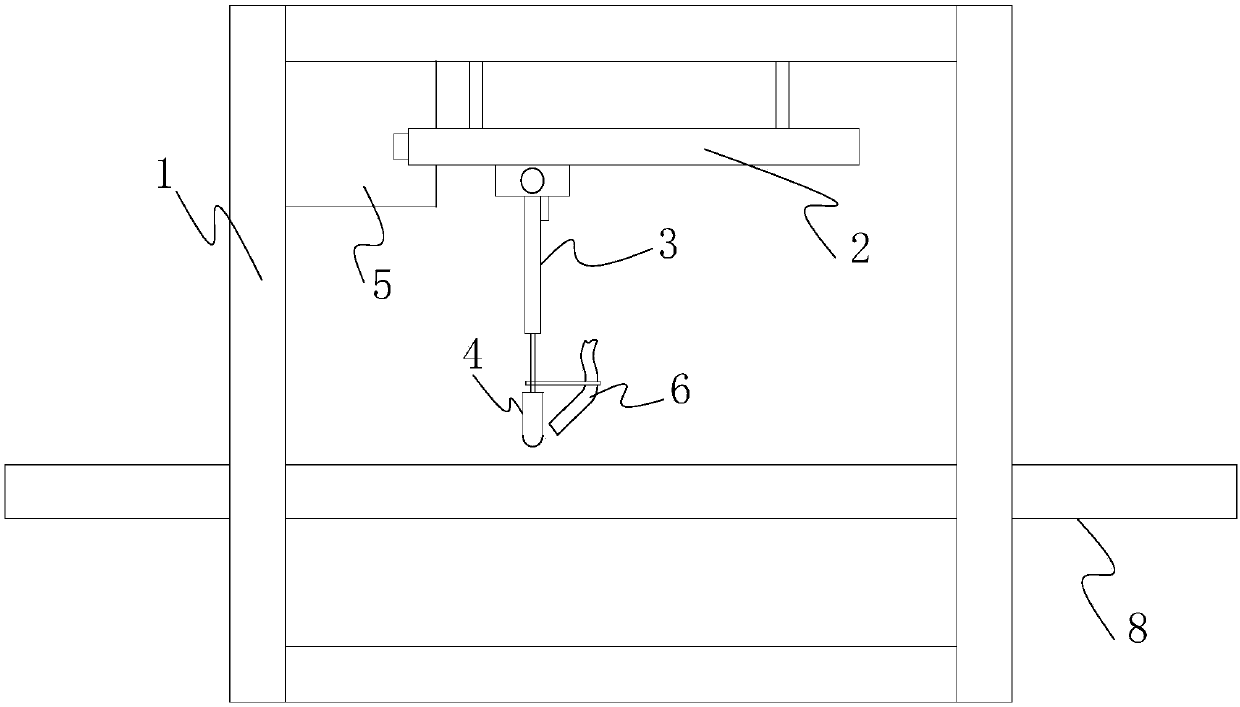

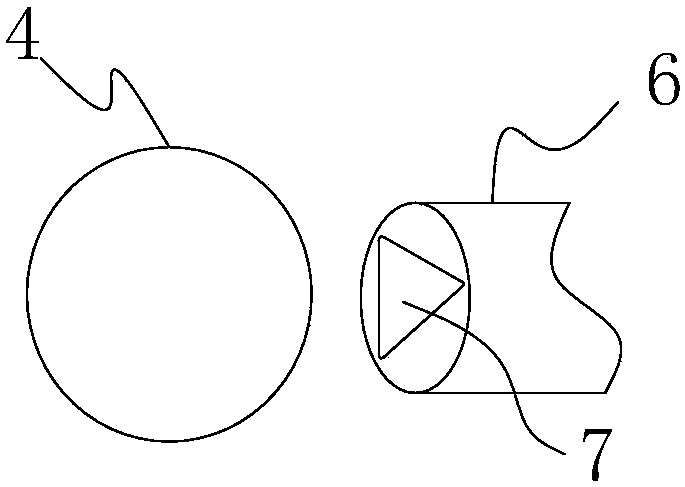

[0017] like figure 1 , 2 As shown, the carpet hot stamping device includes a frame 1, a translation component 2, a lifting component 3, a metal stamping head 4, a temperature control component 5, and a hot air auxiliary heating component.

[0018] The frame 1 is a frame structure, which is deployed in the vertical direction after being placed on the ground. The frame 1 is provided with a hot embossing platform 8 built with a metal plate, and the surface of the hot embossing platform 8 is a horizontal plane. The translation component 2 is an XY-axis servo electric slide, that is, a cross servo electric slide. The translation component 2 is provided with a loading end and a mounting end, and the mounting end is connected to the frame 1. Free movement in the plane. The lifting assembly 3 is a servo electric cylinder, the cylinder body of the servo electric cylinder is fixed on the loading end of the translation assembly 2, the metal hot stamping head 4 is fixedly installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com