A double swing arm multi-bar jacquard warp knitting machine

A multi-bar, double-swing arm technology, which is applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of large motion load on the groove needle bed, reduced speed of warp knitting machine, slow speed of warp knitting machine, etc., and achieves Reduced swing load, increased speed, and light load effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

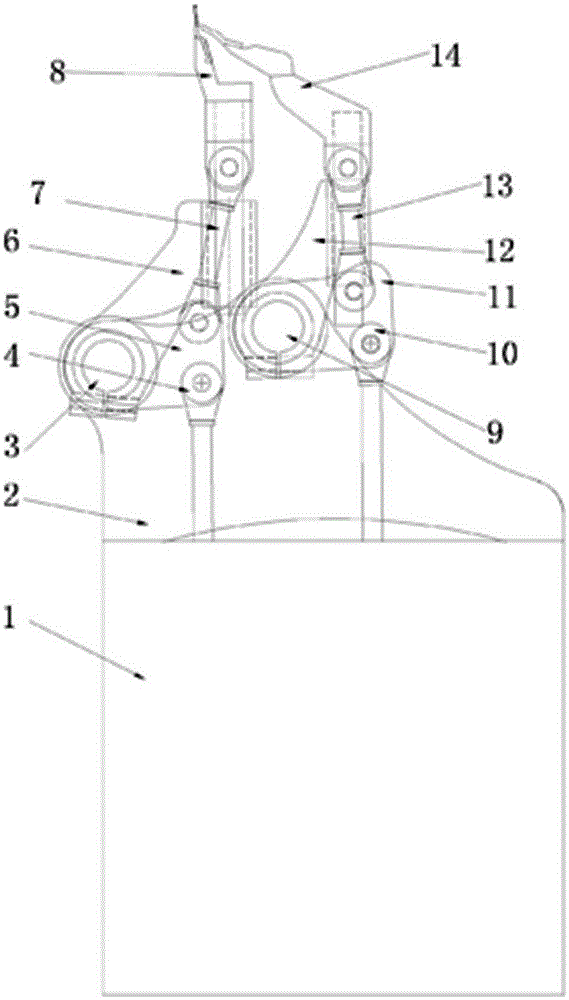

[0013] Below in conjunction with accompanying drawing and embodiment, structure and working principle of the present utility model are described in detail:

[0014] A double-swing arm multi-bar jacquard warp knitting machine, comprising: a box body (1), a swing shaft support (2), a slotted needle swing shaft (3), a slotted needle pull-down handle (4), a slotted needle swing arm ( 5), grooved needle guide seat (6), grooved needle pull rod (7), grooved needle bed (8), needle core swing shaft (9), needle core pull-down handle (10), needle core swing arm (11), needle Core guide seat (12), needle core pull bar (13), needle core bed (14). Its main features are: the grooved needle bed (8) and the needle core bed (14) are respectively driven by their respective transmission mechanisms, so that the needle core bed (14) and the grooved needle bed (8) work separately and cooperate with each other to realize the loop forming work .

[0015] In the double-swing arm multi-bar jacquard war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com