Annular steel wire detector

A detector and steel wire technology, applied in the field of steel wire, can solve the problems of low accuracy and low efficiency of manual detection of broken steel wires, and achieve the effects of improving production quality, light burden, and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

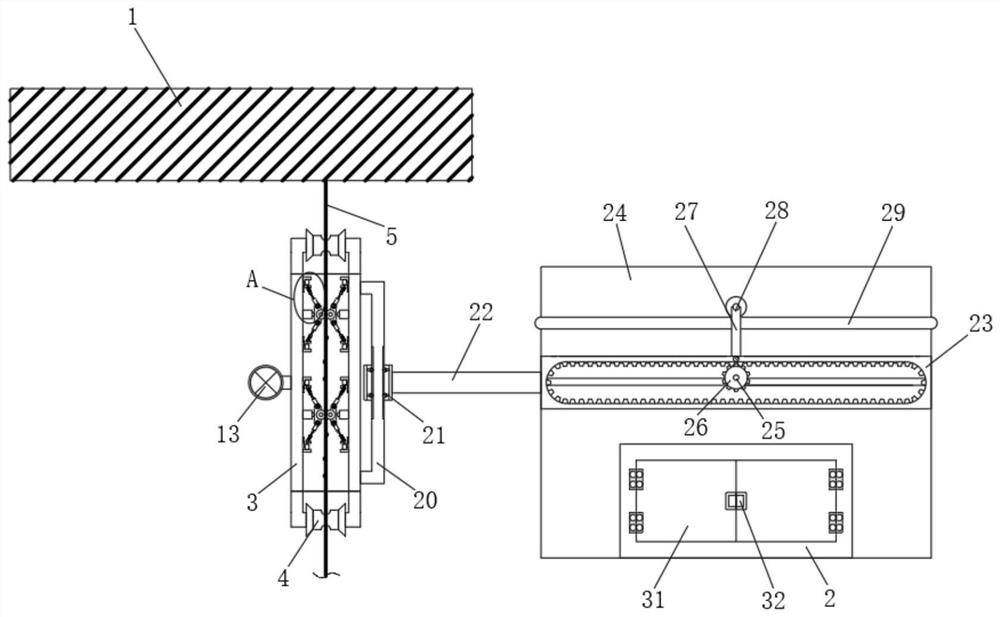

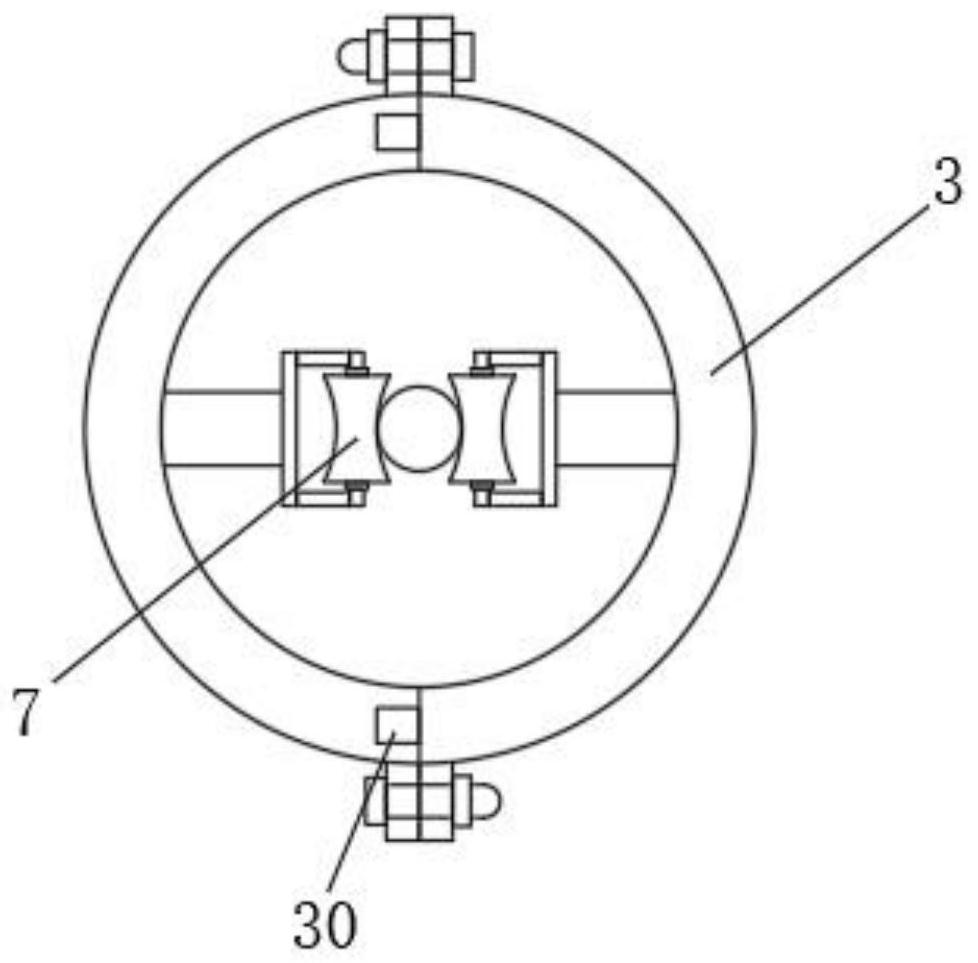

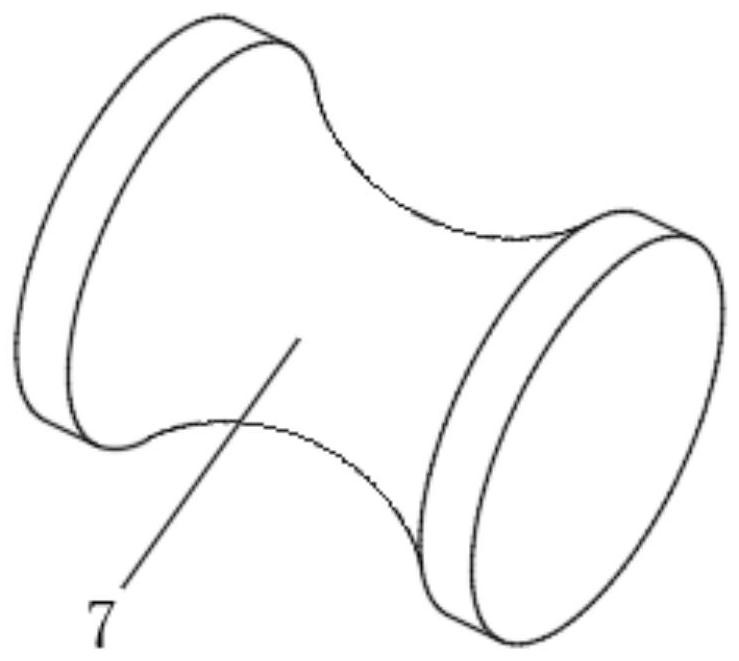

[0024] refer to Figure 1-5 , a ring-shaped steel wire detector, including a bracket 1, a main control box 2 and a sleeve 3, a steel wire broken wire detector is arranged in the sleeve 3, the principle of the detector is to use a steel wire rope as a magnetic material, and in a magnetic field It can show good magnetic permeability. Therefore, a closed magnetic circuit is formed between the steel wire rope, the air gap, the magnetic source and the armature. When there is a broken wire outside the steel wire rope, the local reluctance near the broken wire will change. In this way, the broken wire There is a special magnetic field area on the outer surface of the main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com