A vacuum melting device for non-oxide optical glass

A vacuum melting, optical glass technology, applied in glass production, glass furnace equipment, glass manufacturing equipment and other directions, can solve the problems affecting the non-oxide optical glass yield product stability, glass homogenization effect and production efficiency is not high, wire Or the brush is easily damaged, etc., to improve the efficiency of vacuum melting, improve production efficiency and product yield, and avoid abnormal power failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

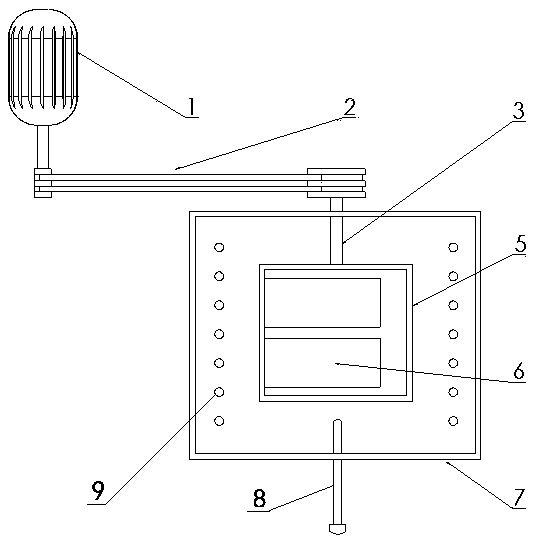

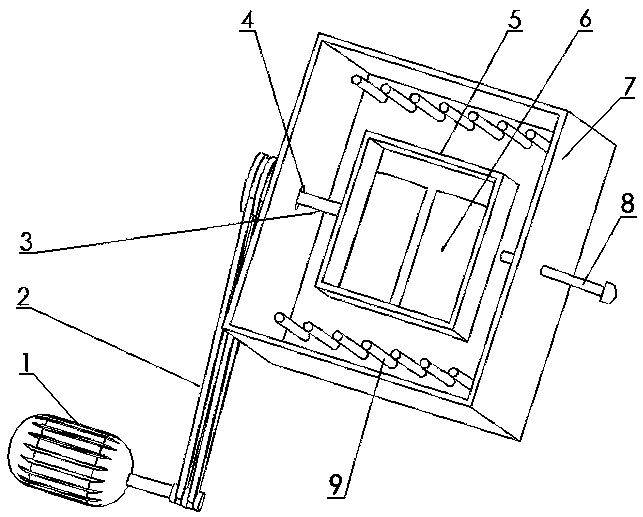

[0012] Such as figure 1 , 2 As shown, the invention provides a vacuum melting device for non-oxide optical glass, which realizes vacuum melting of non-oxide optical glass. The invention consists of two parts, a smelting furnace body and a swing device. Among them, the smelting furnace body includes a furnace body 7, a heating element 9 and a vacuum melting container 6, a through hole is arranged on one side of the furnace body 7, and the heating element 9 is made of silicon carbide rod or resistance wire, and can be arranged horizontally or vertically. Or the circle is installed between the swing box 5 and the furnace body 7, which is heated by indirect heating, and is suitable for non-oxide optical glass with a low melting point. Furnace body 7 is built with unshaped lightweight refractory bricks, and the outside of the refractory material is welded by steel to form a furnace structure. After the smelting furnace body is repaired, the swing box 5 is placed in the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com