Simple cloth inspection, correction and cloth rolling integrated device

A simple and cloth inspection technology, applied in the field of knitting machinery, can solve the problems of delaying a lot of time, wasting a lot of time, wasting labor, etc., and achieving the effects of convenient use, energy saving, and labor cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

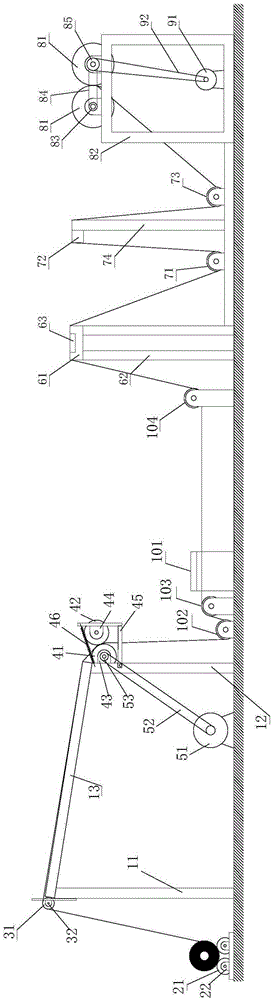

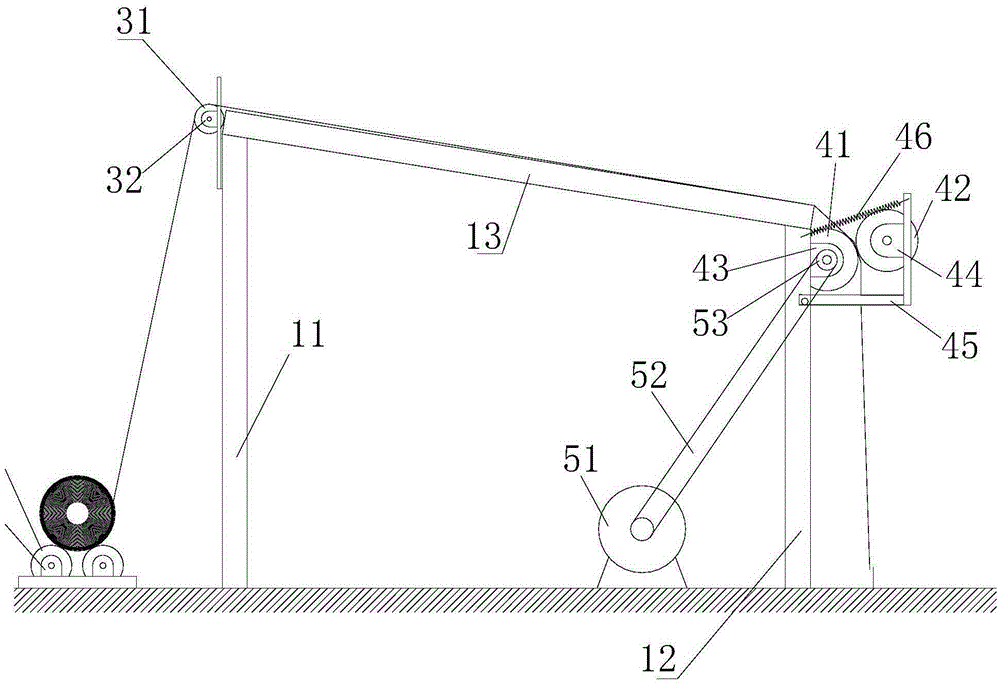

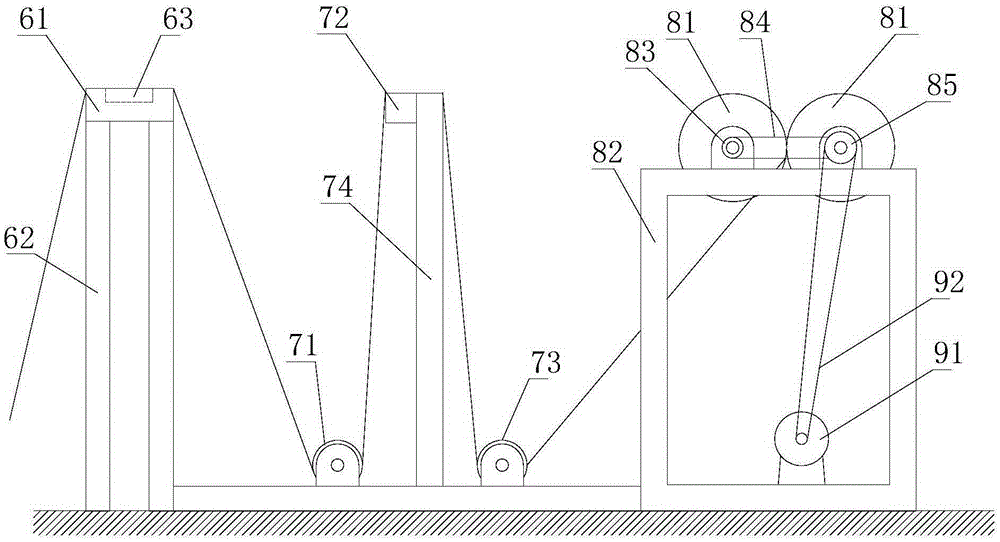

[0025] The present invention is described in detail below in conjunction with accompanying drawing description:

[0026] like figure 1 As shown: the present invention includes a frame, a positioning roller device, a guide roller device, a power roller device, and a first power device with a switch for driving the power roller device to roll; the frame is used to support the unfolded The cloth, position roller device, guide roller device, and power roller device together realize the stable unfolding of the cloth. The first power device provides power for the power roller device. The first power device here has a switch, and the switch is generally placed In a place within easy reach of the workers, when the defect is found during the cloth inspection, stop feeding the cloth and mark the defect.

[0027]Described frame is to comprise four support feet and support plate 13, and wherein, four support feet are arranged in a square shape, and wherein front two support feet are of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com