Coal mine underground isolated soft rock mass supporting device used in dynamic pressure environment

A supporting device and rock mass technology, applied in shaft equipment, shaft lining, underground chambers, etc., can solve problems such as difficult mining technology, hidden dangers for underground workers, and short service life of roadways, so as to prevent roof accidents in coal mines occurrence, increase coal output and benefits, and reduce the effect of roadway support materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

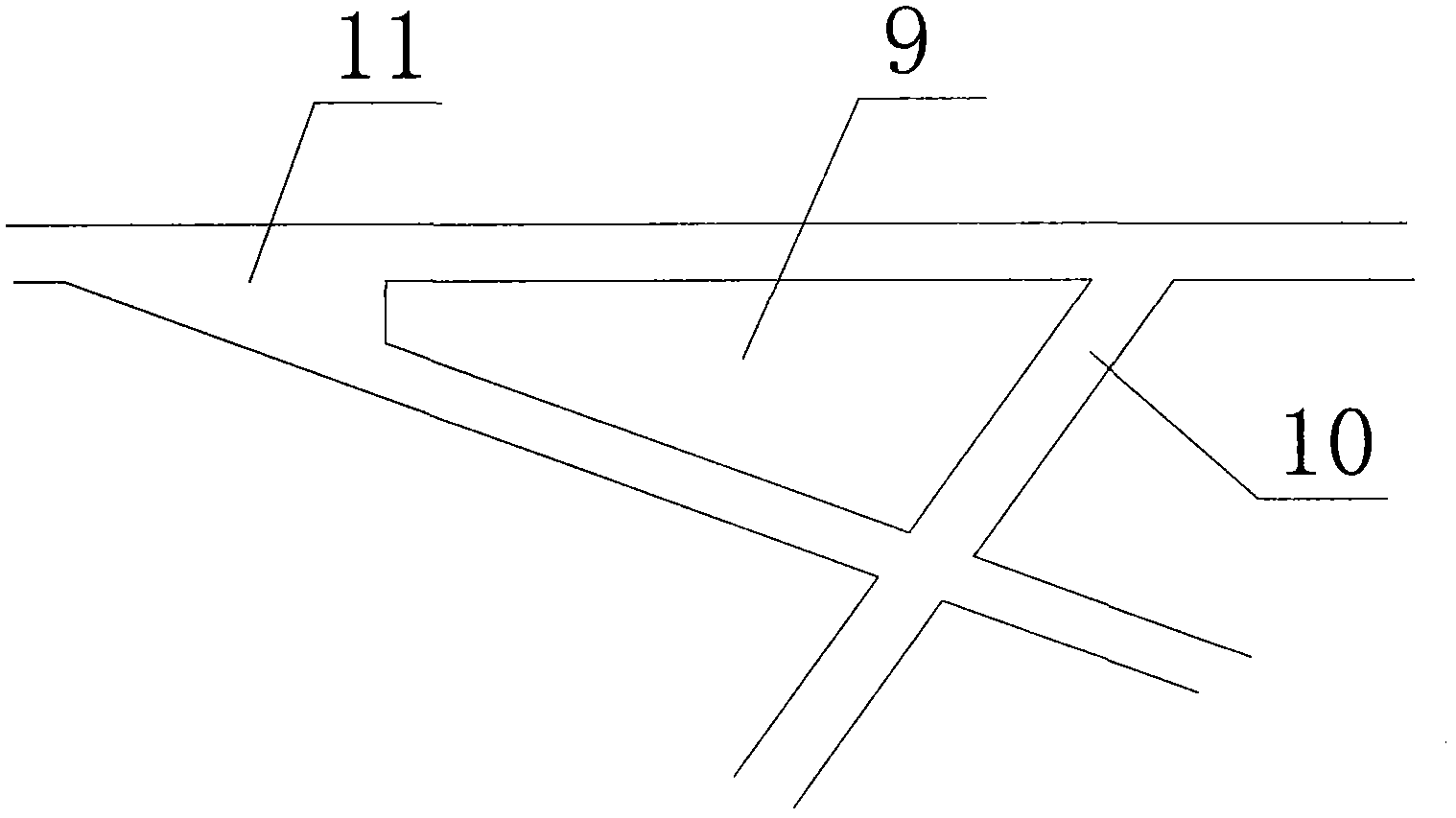

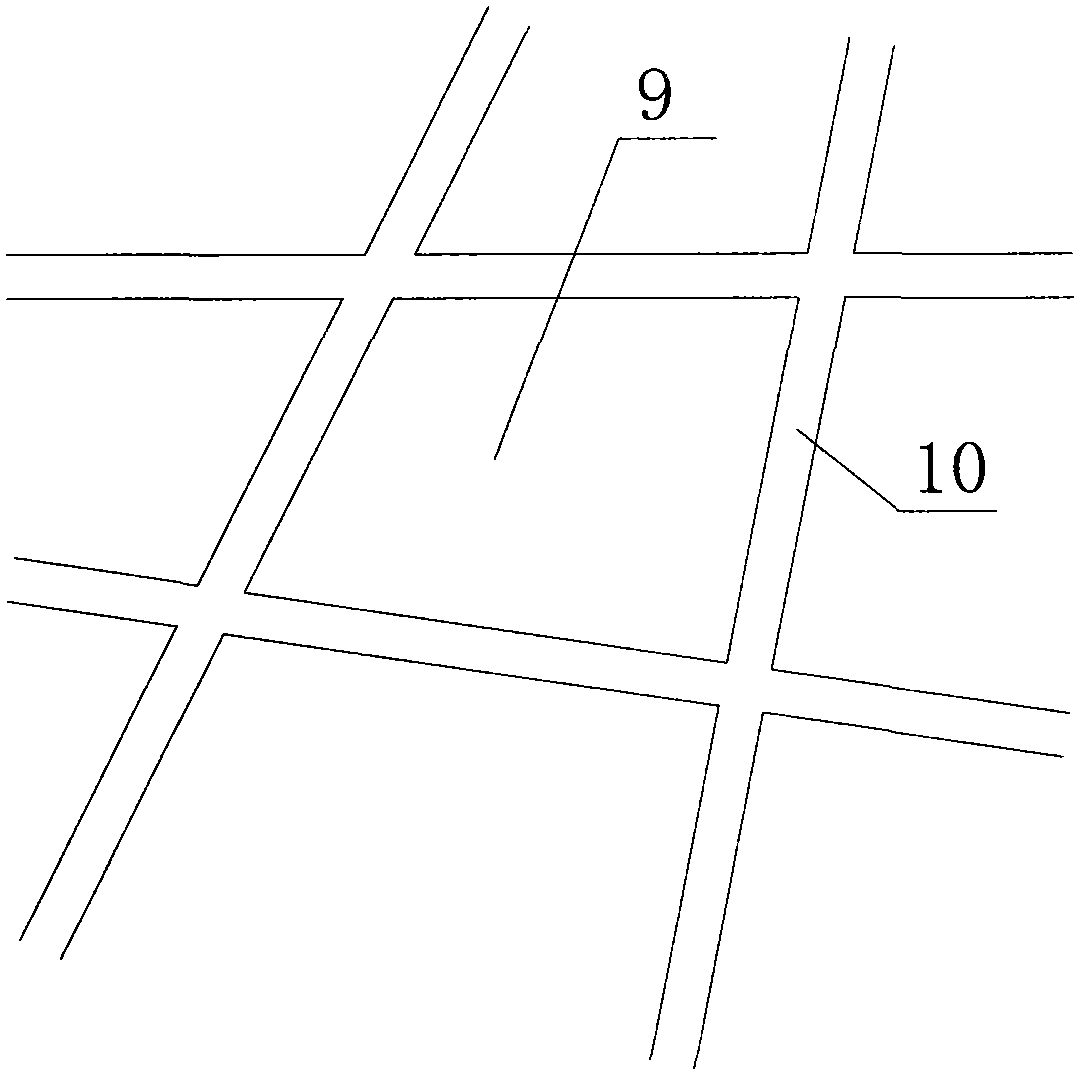

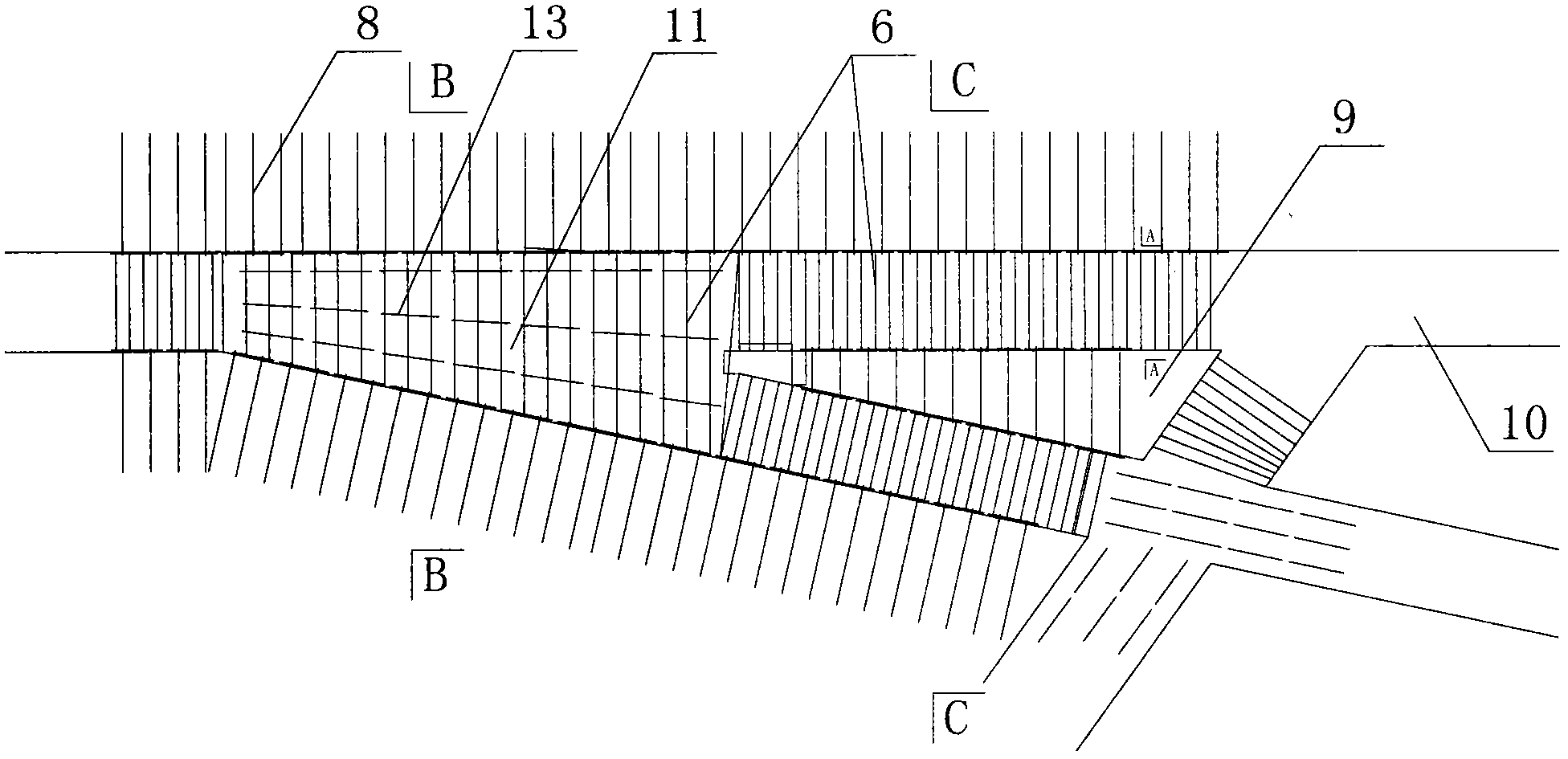

[0022] Such as figure 1 and figure 2 As shown, the isolated island soft rock mass support device under the coal mine underground dynamic pressure environment is aimed at the isolated island soft rock mass 9 and the island surroundings in the three-fork gate and four-fork gate structure of the isolated island soft rock roadway under the coal mine underground dynamic pressure environment. Roadway 10 and soft rock roadway intersection 11 are supported.

[0023] Such as image 3 and Figure 4 As shown, the island soft rock roadway of the isolated island soft rock roadway support device under the coal mine underground dynamic pressure environment of this embodiment includes a roadway side 1 , a roadway top 2 and a roadway bottom 3 . A layer of anchor net-4 is arranged on the side of the roadway 1 and the top 2 of the roadway. On the anchor net-4 and perpendicular to the inner wall of the roadway side 1 and the inner wall of the roadway top 2, the anchor rod-5 is equidistantly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com