Manifold assembly with three-way catalyst

A three-way catalytic converter and catalytic converter technology, which is applied in the direction of engine components, machines/engines, noise reduction devices, etc., can solve the problems of poor purification effect and difficulty in reaching National IV, so as to improve the effect and shorten the light-off time, the effect of increasing the working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, and have no limiting effect on it.

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

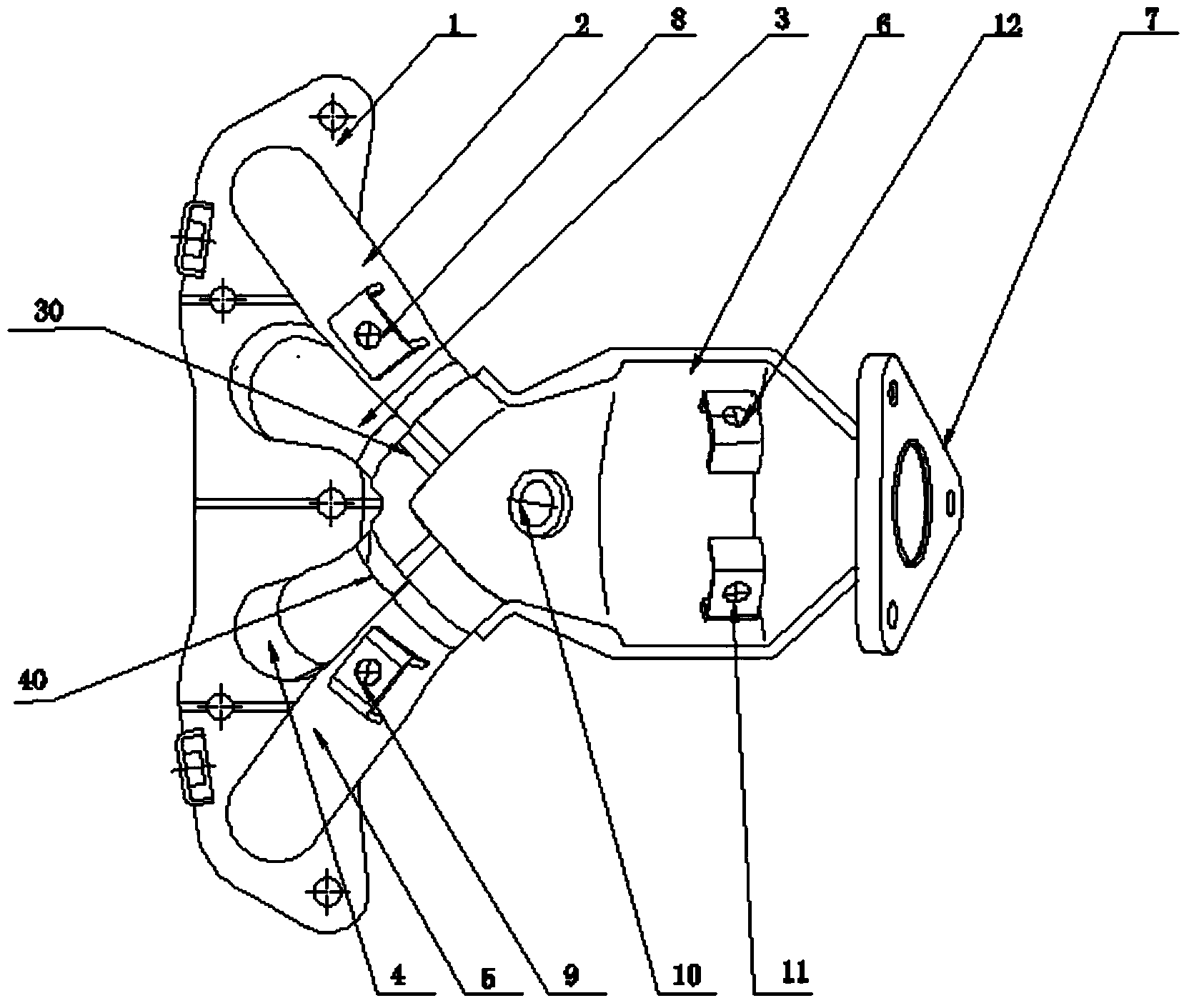

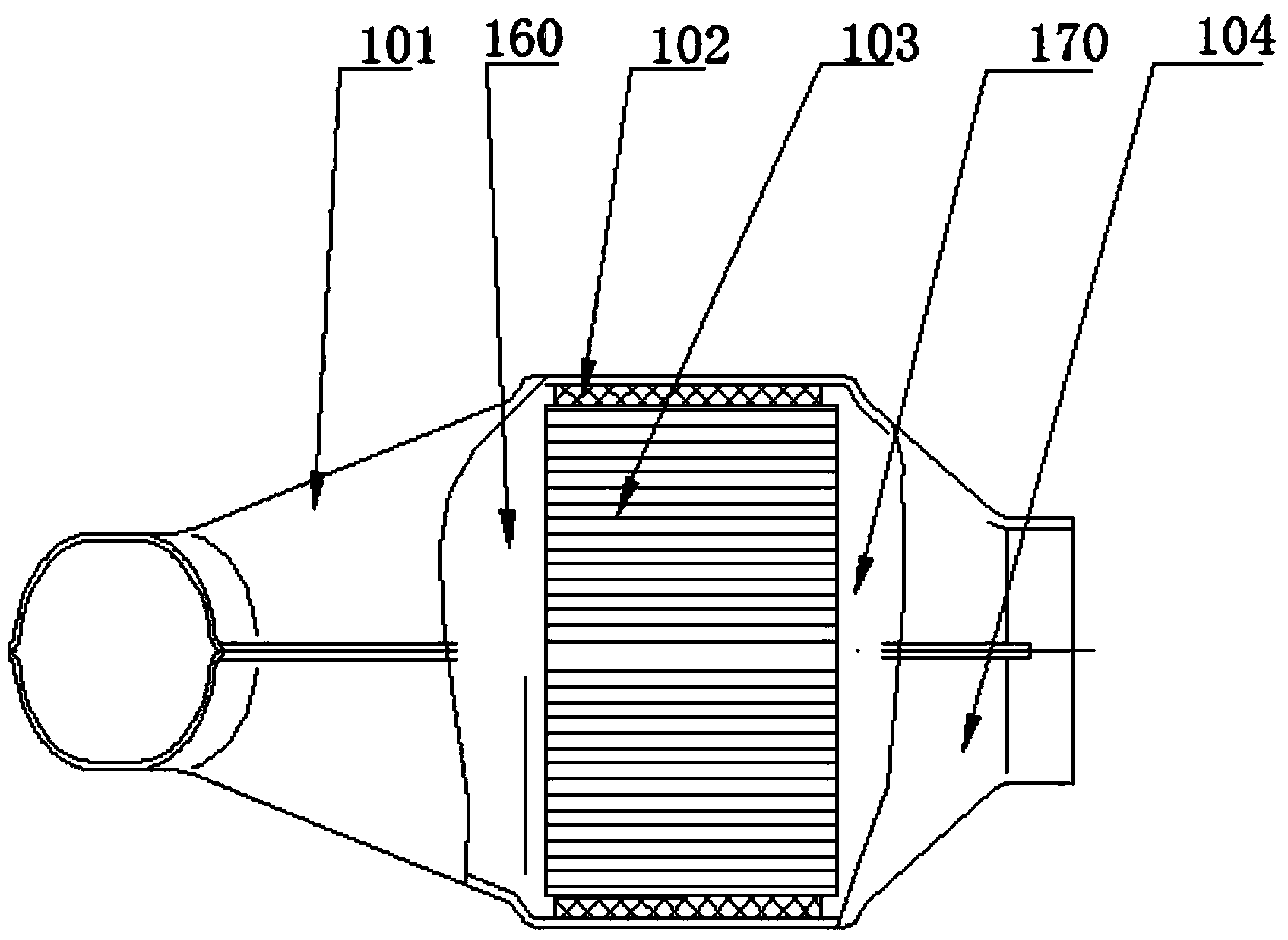

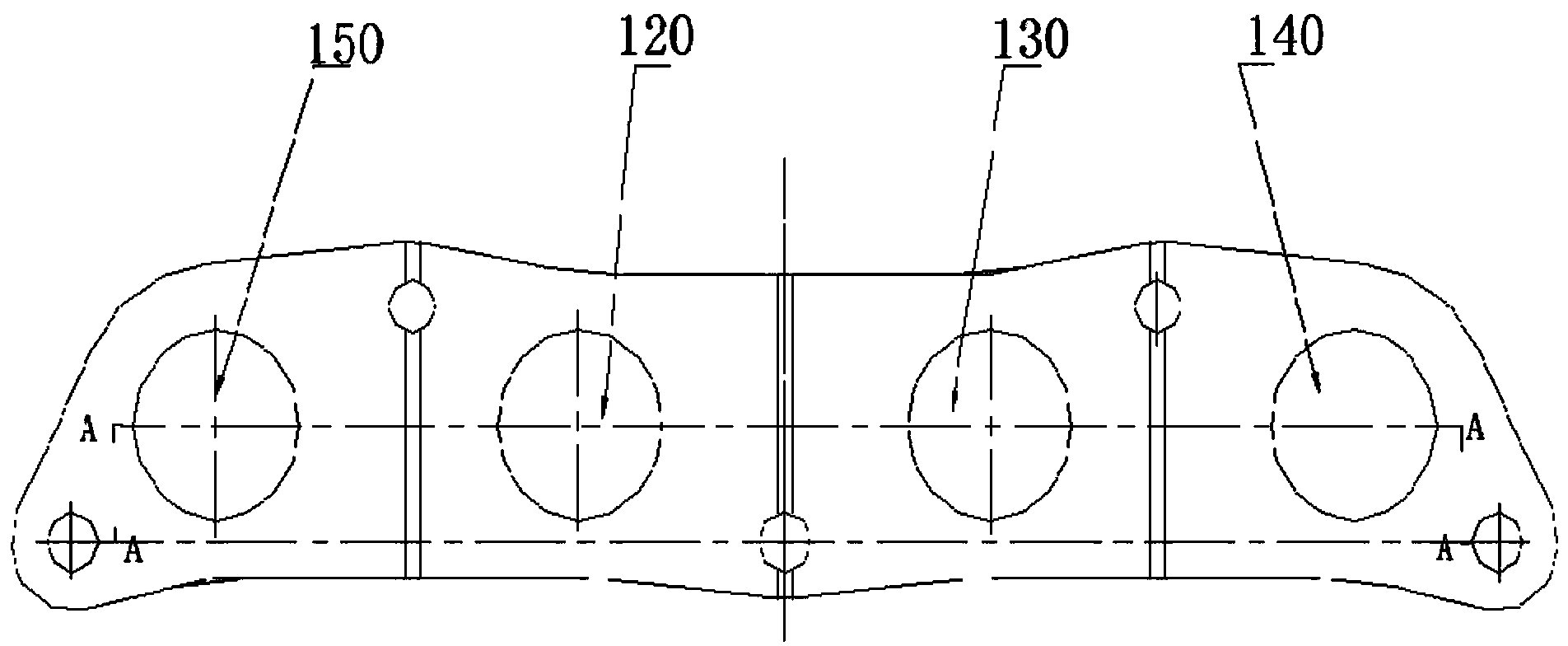

[0014] Such as Figure 1-2 As shown, the present invention provides a manifold assembly with a three-way catalytic converter, including three intake flanges with a width of 3±0..5 thermal deformation resistance grooves passing through the installation holes 1, and four exhaust flanges Manifold 2-5, catalyst body 6, outlet flange 7, catalyst body includes upper casing 101, lower casing 104, oxygen sensor nut 8-10, catalyst 103 and gasket 104. Among them, the four exhaust manifolds are respectively connected with the four intake ends (the intake end can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com