Variable cylinder engine

An engine and cylinder technology, applied in the field of variable cylinder engines, can solve the problems of longer time required for stopping and inability to transfer smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] (1) The overall structure of the engine

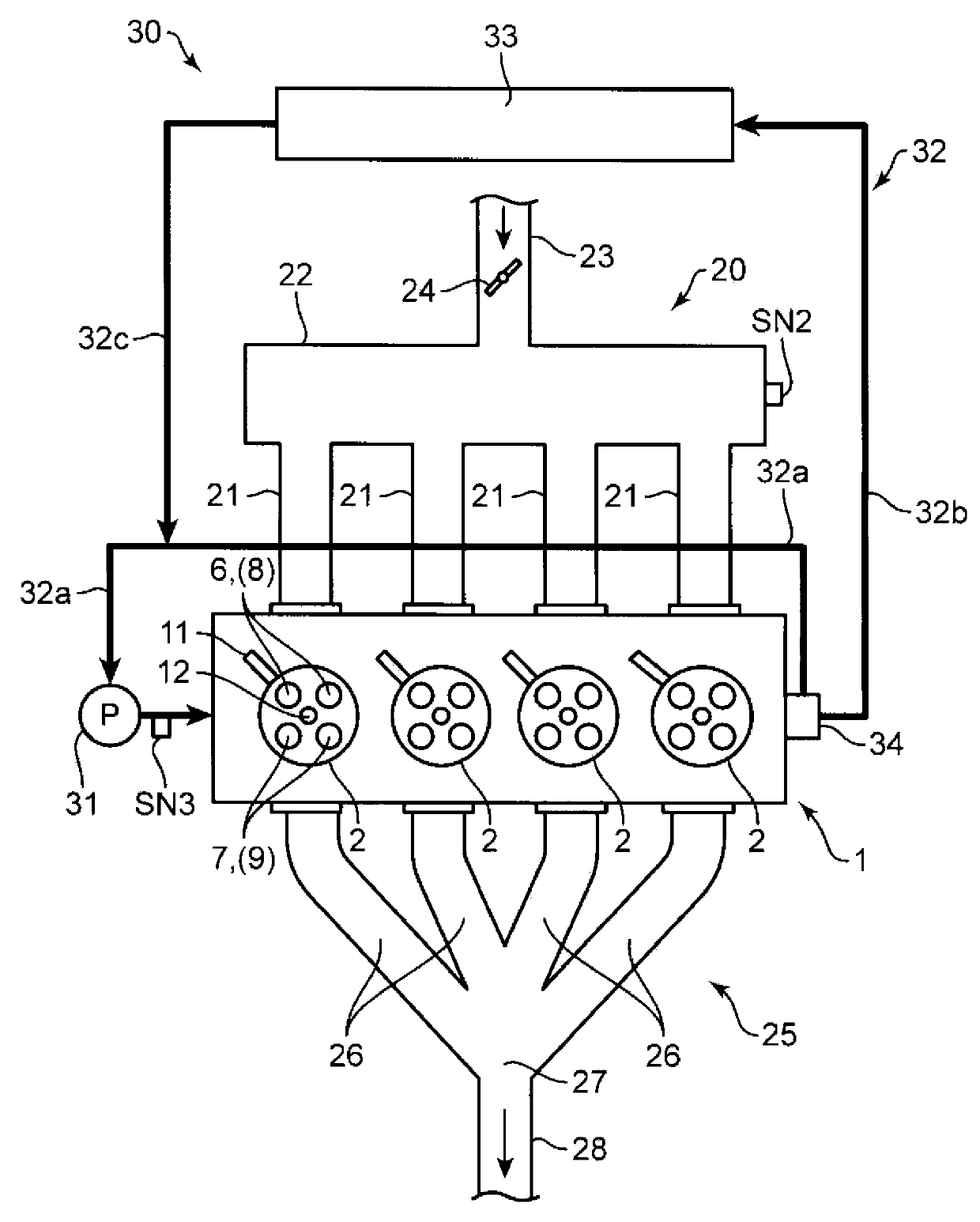

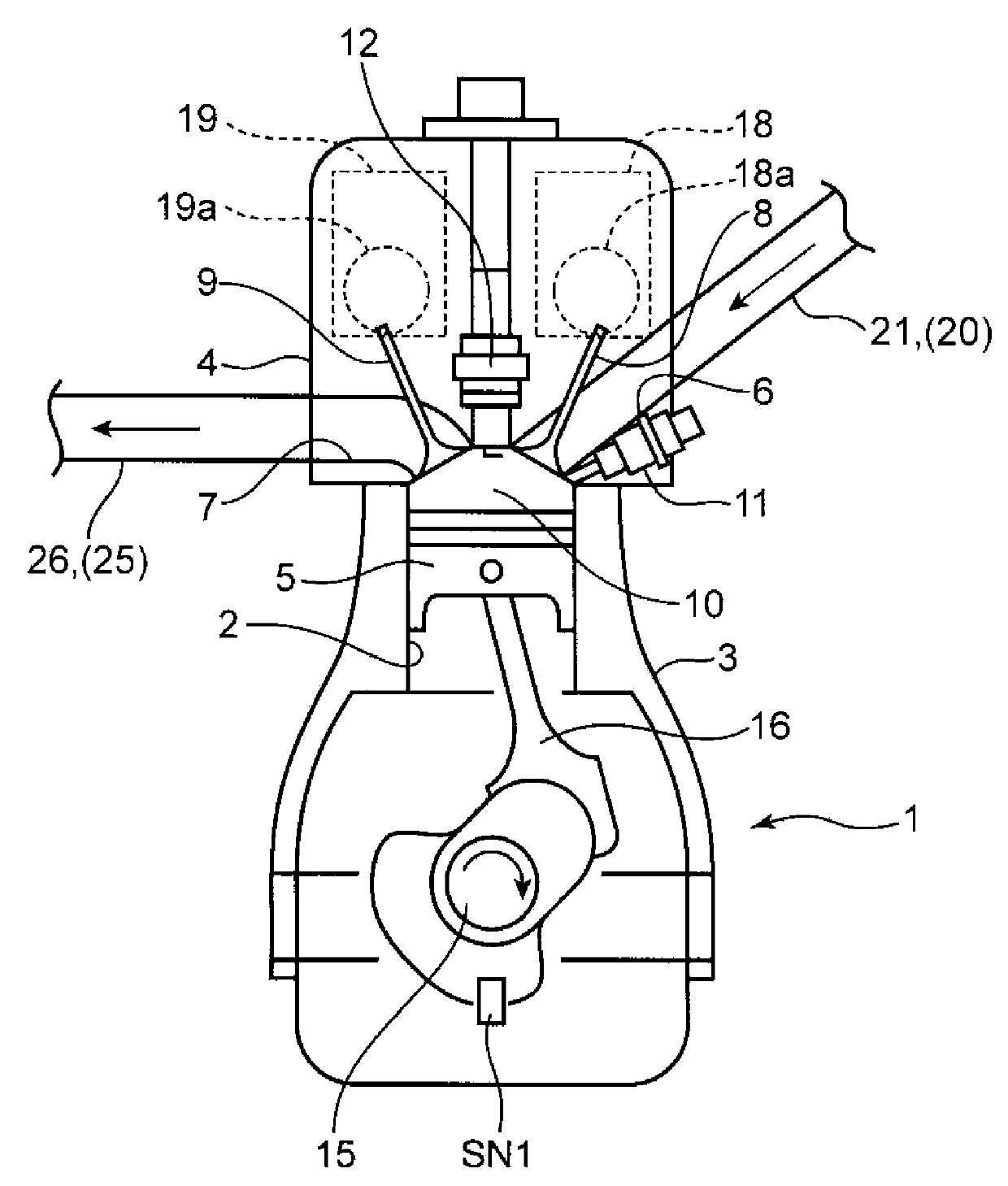

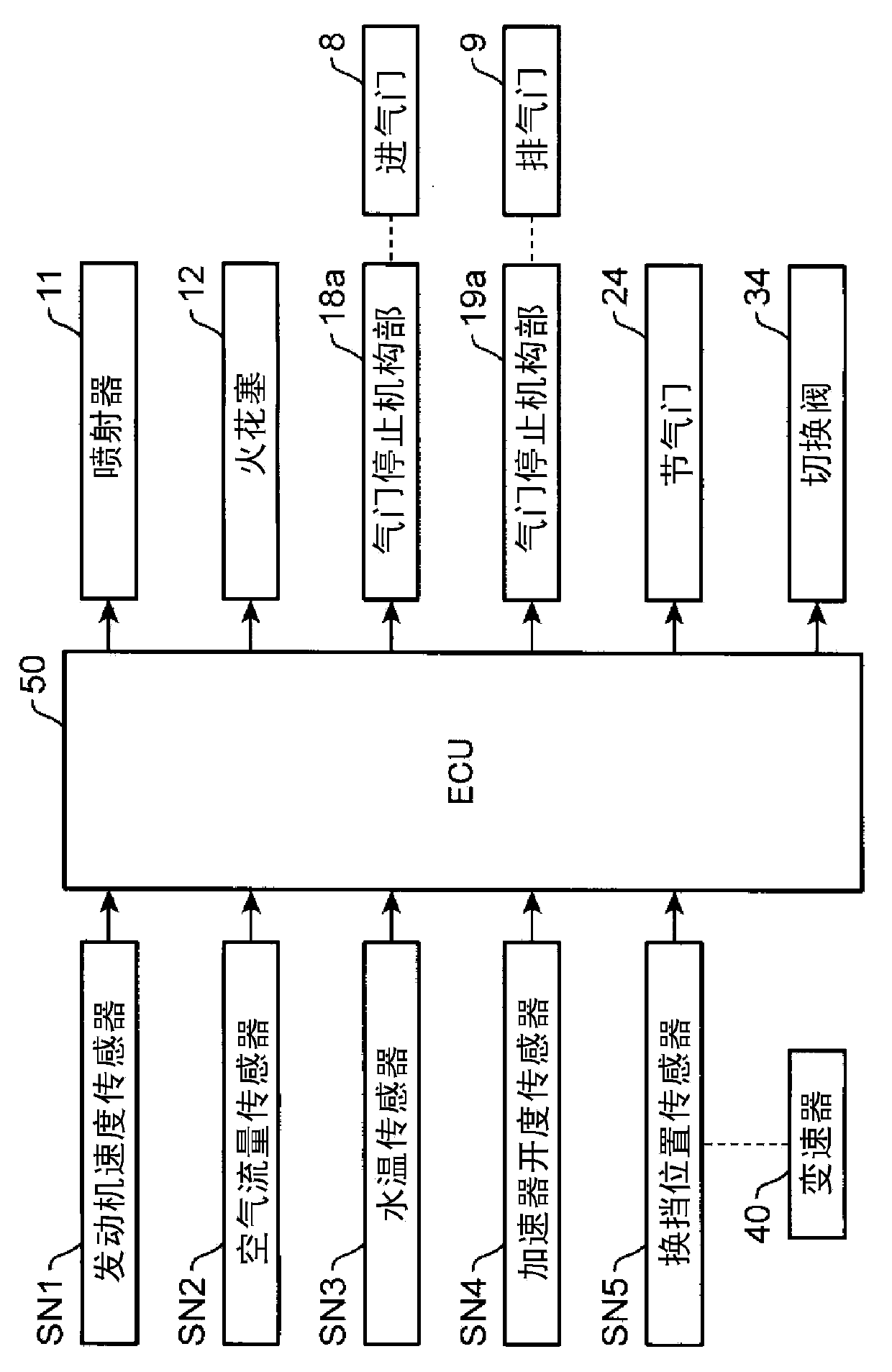

[0048] figure 1 and figure 2 It is a figure which shows the structure of the variable cylinder engine which concerns on one Embodiment of this invention. The engine shown in these figures is a four-stroke multi-cylinder gasoline engine mounted on a vehicle as a driving power source. Specifically, the engine has: an inline four-cylinder engine body 1 having four cylinders 2 arranged in a straight line; an intake passage 20 for introducing air into the engine body 1; The exhaust passage 25 for the exhaust gas generated in the engine; the cooling mechanism 30 for cooling the engine body 1 .

[0049] The engine main body 1 has: a cylinder block 3 in which the four cylinders 2 are formed; a cylinder head 4 provided on the upper portion of the cylinder block 3; and a piston 5 reciprocally slidably inserted into each cylinder 2 .

[0050] A combustion chamber 10 is formed above the piston 5 , and fuel containing gasoline as a main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com