Negative pressure supply device for engine

A technology for supplying devices and engines, which is applied to engine components, combustion engines, machines/engines, etc., can solve the problems of complex piping structure and large number of components, and achieve the effects of easy layout, improved performance, and improved rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

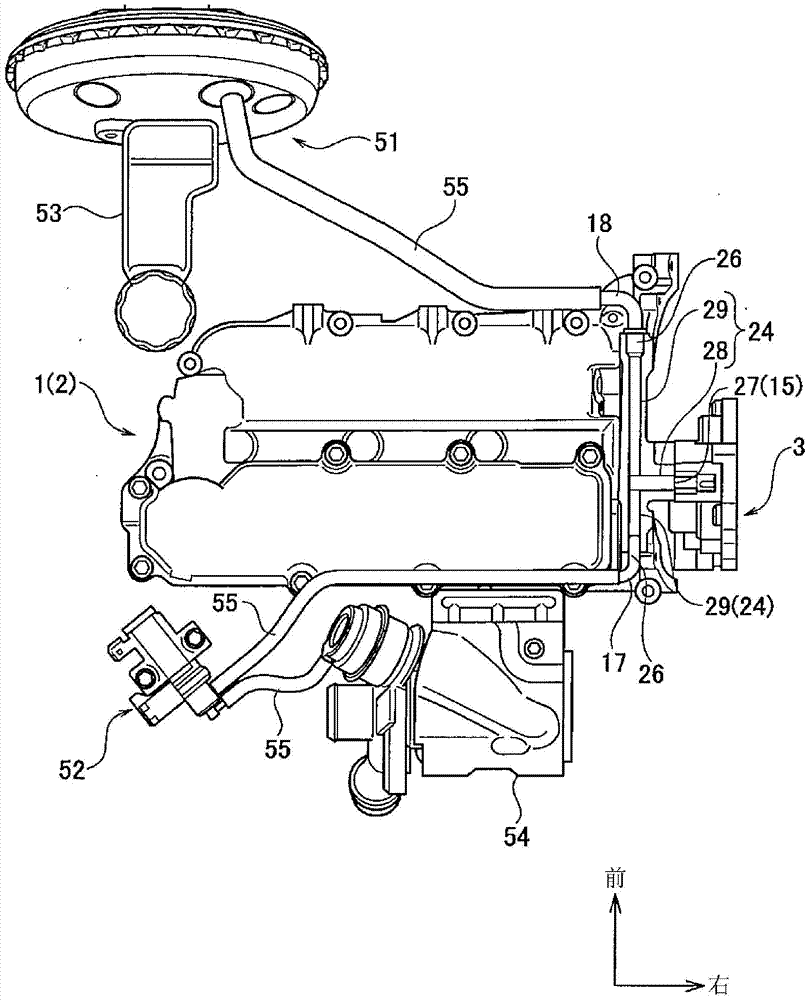

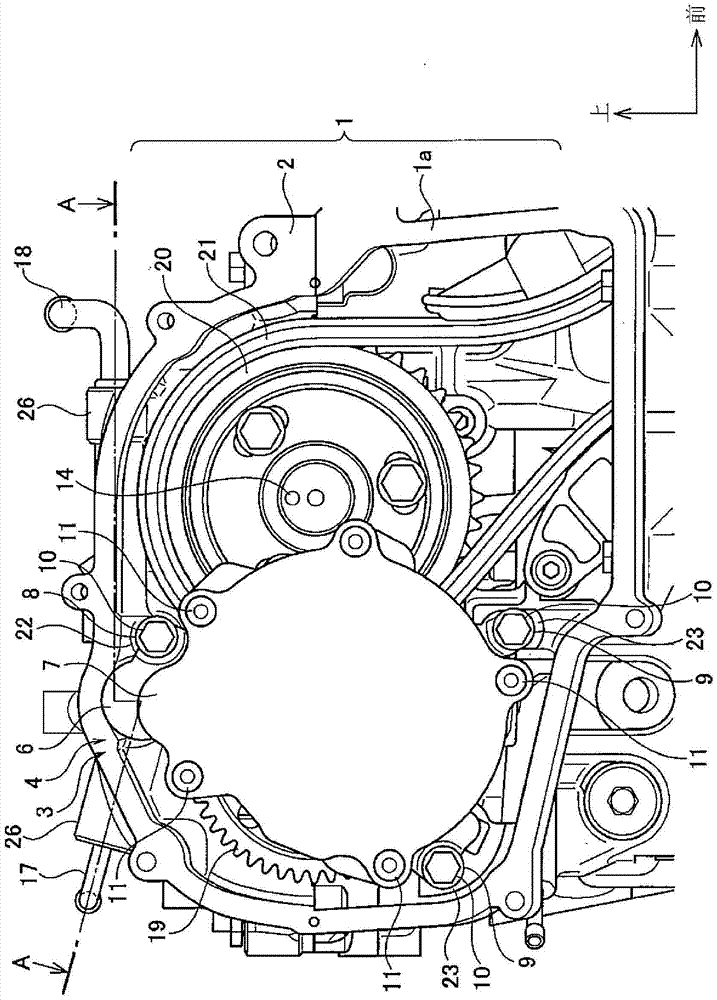

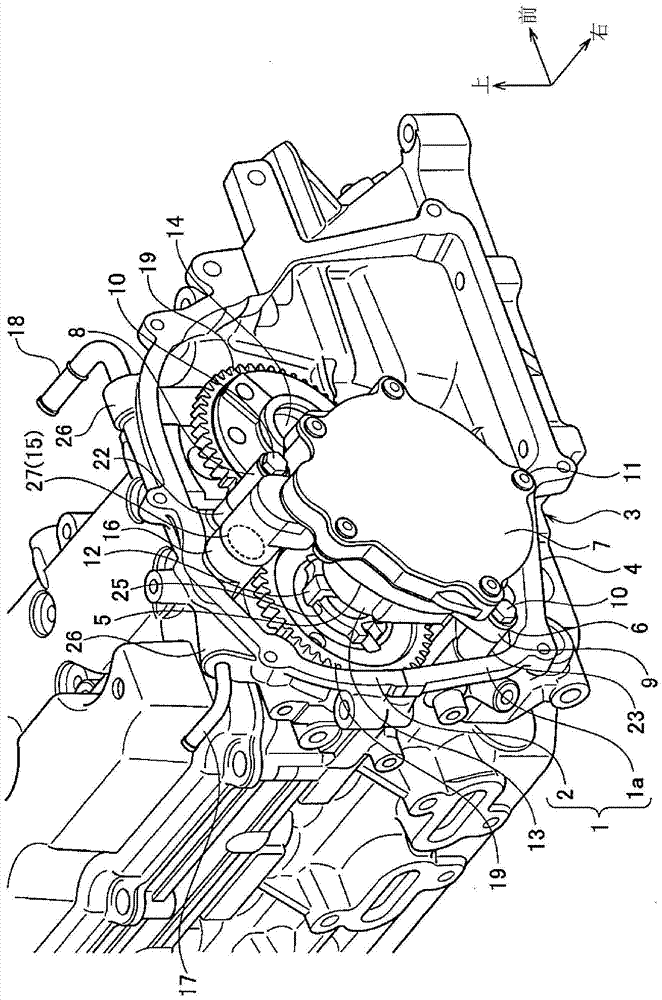

[0015] An embodiment of a negative pressure supply device for an engine according to the present invention will be described below with reference to the drawings. figure 1 is a plan view of the cylinder head of the present embodiment, figure 2 is showing figure 1 Front view of the assembly structure of the vacuum pump in the cylinder head, image 3 yes figure 1 Perspective view of the negative pressure supply device in the cylinder head. In the engine of the present embodiment, a cylinder head 1 is mounted above a cylinder block (not shown). The cylinder head 1 of the present embodiment includes: a cylinder head lower portion 1a mounted above the cylinder block; and a cam box 2 mounted above the cylinder head lower portion 1a. In addition, the engine main body is mounted on the vehicle in various directions, but usually the cylinder head 1 is mounted above the cylinder block, so this direction is defined as the upper side of the engine, and the opposite direction is defin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com