Torque limiter

A technology of torque limiters and components, applied in clutches, couplings, slip couplings, etc., can solve the problems of head flying of shear valves, damage and loss of torque limiters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the present invention will be described in detail with reference to the drawings.

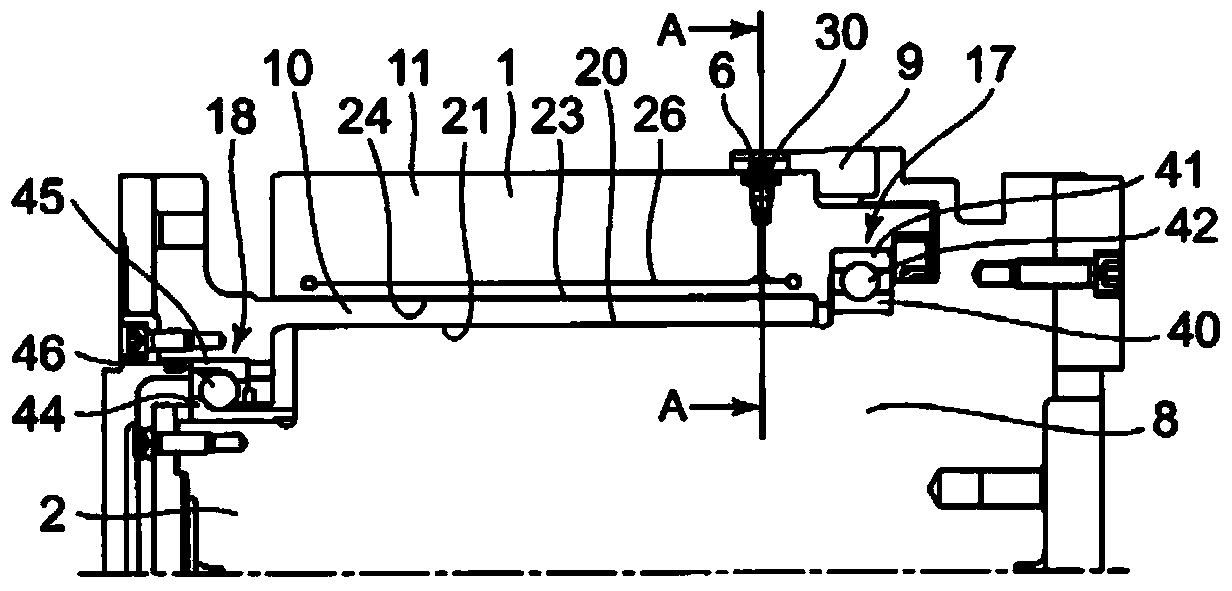

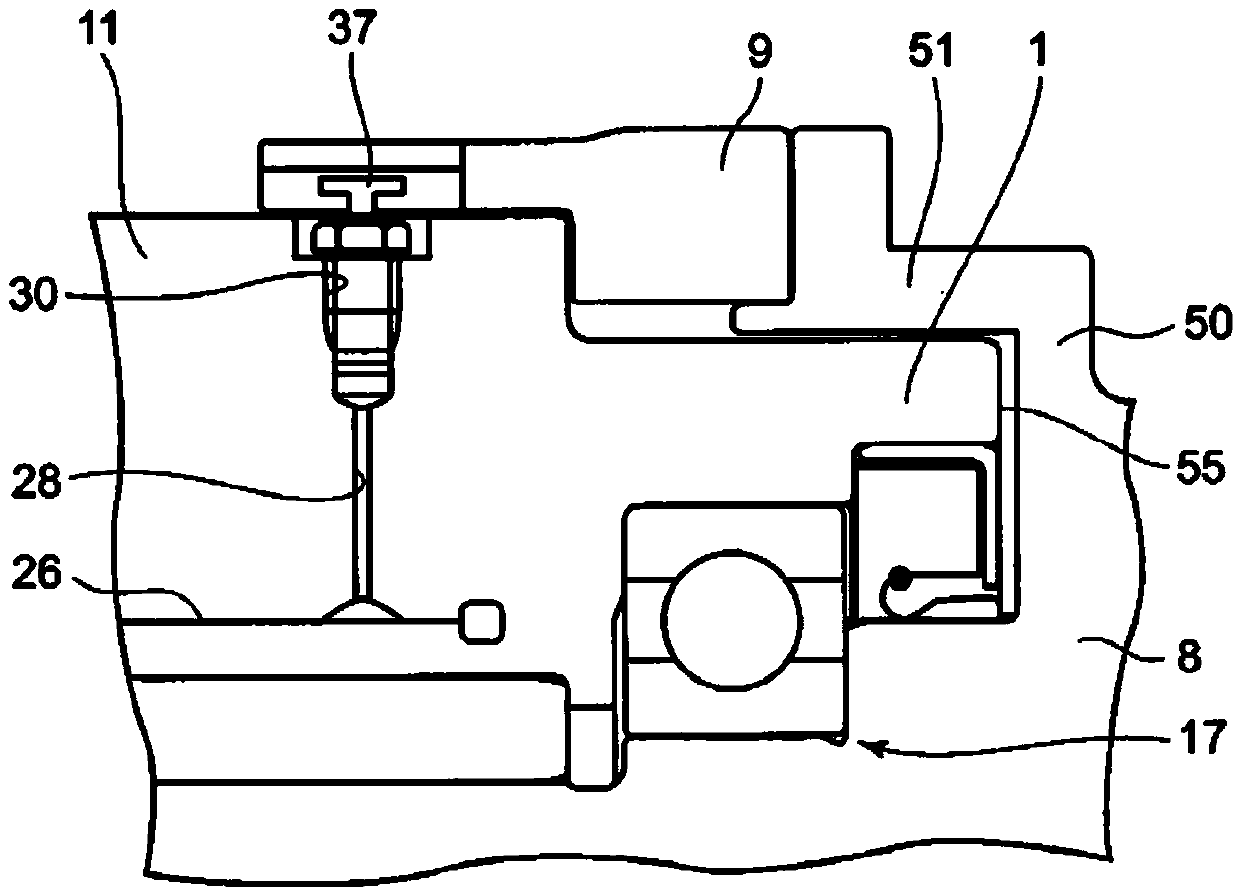

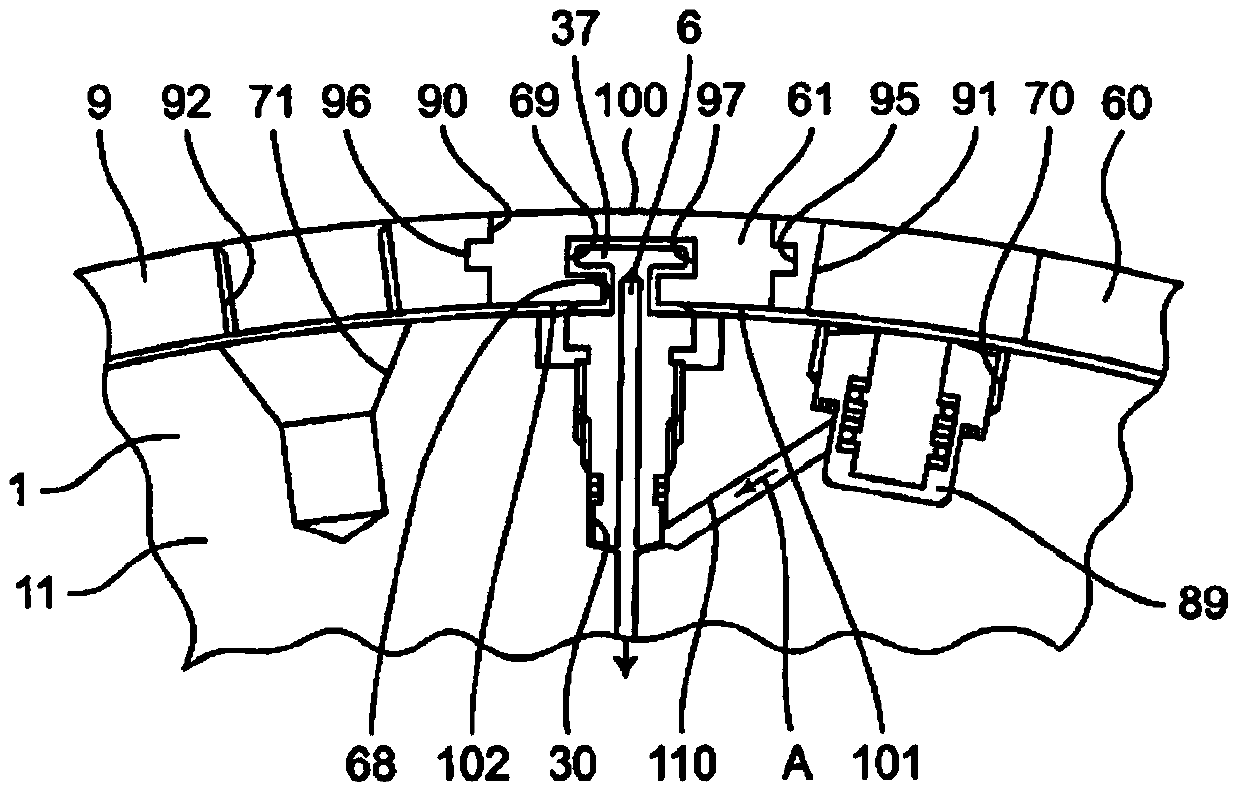

[0015] figure 1 It is a schematic cross-sectional view in the axial direction of the torque limiter according to the first embodiment of the present invention.

[0016] This torque limiter includes a cylindrical member 1 as one member, a shaft member 2 as the other member, four shear valves 6 , ball bearings 17 and ball bearings 18 .

[0017] The above-mentioned cylinder member 1 is composed of a first cylinder member 10 and a second cylinder member 11 . The first cylindrical member 10 has a substantially cylindrical inner peripheral surface 21 that is in contact with the outer peripheral surface 20 of the shaft member 2 . Lubricating oil for preventing seizing exists between the outer peripheral surface 20 of the shaft member 2 and the inner peripheral surface 21 of the first cylinder member 10 . The second cylindrical member 11 has a substantially cylindrical inner peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com