Dust remover by-pass valve

A dust collector and bypass valve technology, which is applied to lift valves, valve devices, engine components, etc., can solve the problems of easy dust accumulation of bypass valves and low installation accuracy requirements, achieve low production and installation accuracy requirements, and ensure long-term reliability. Use and ensure the effect of zero leakage of the bypass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

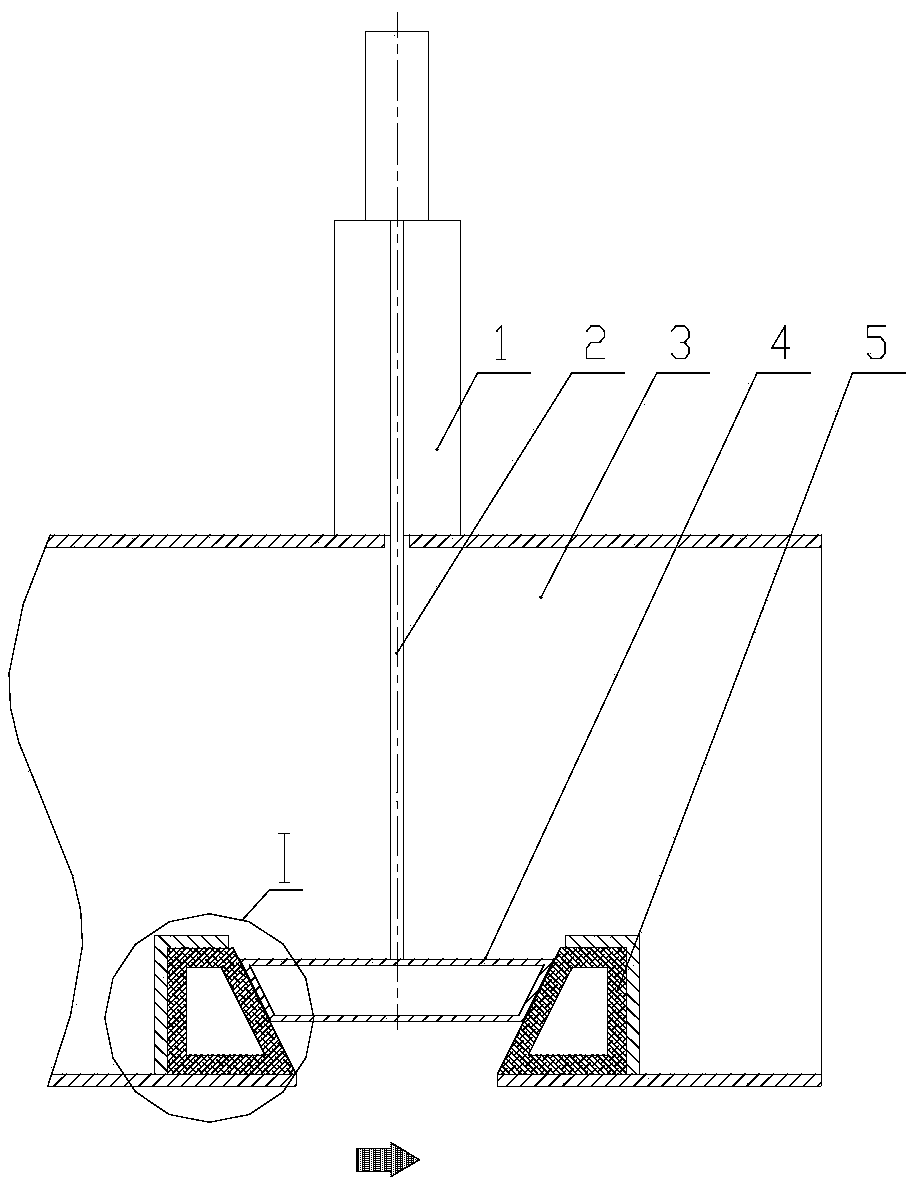

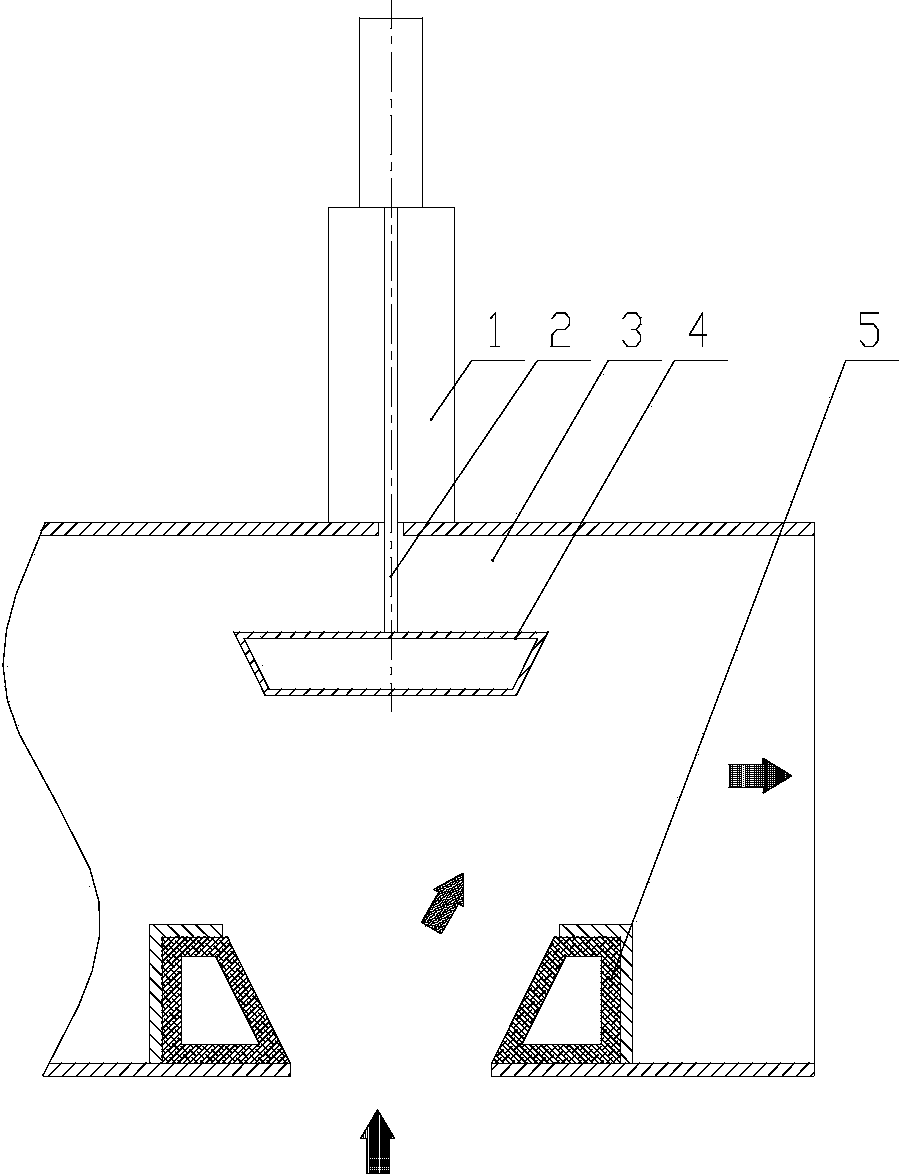

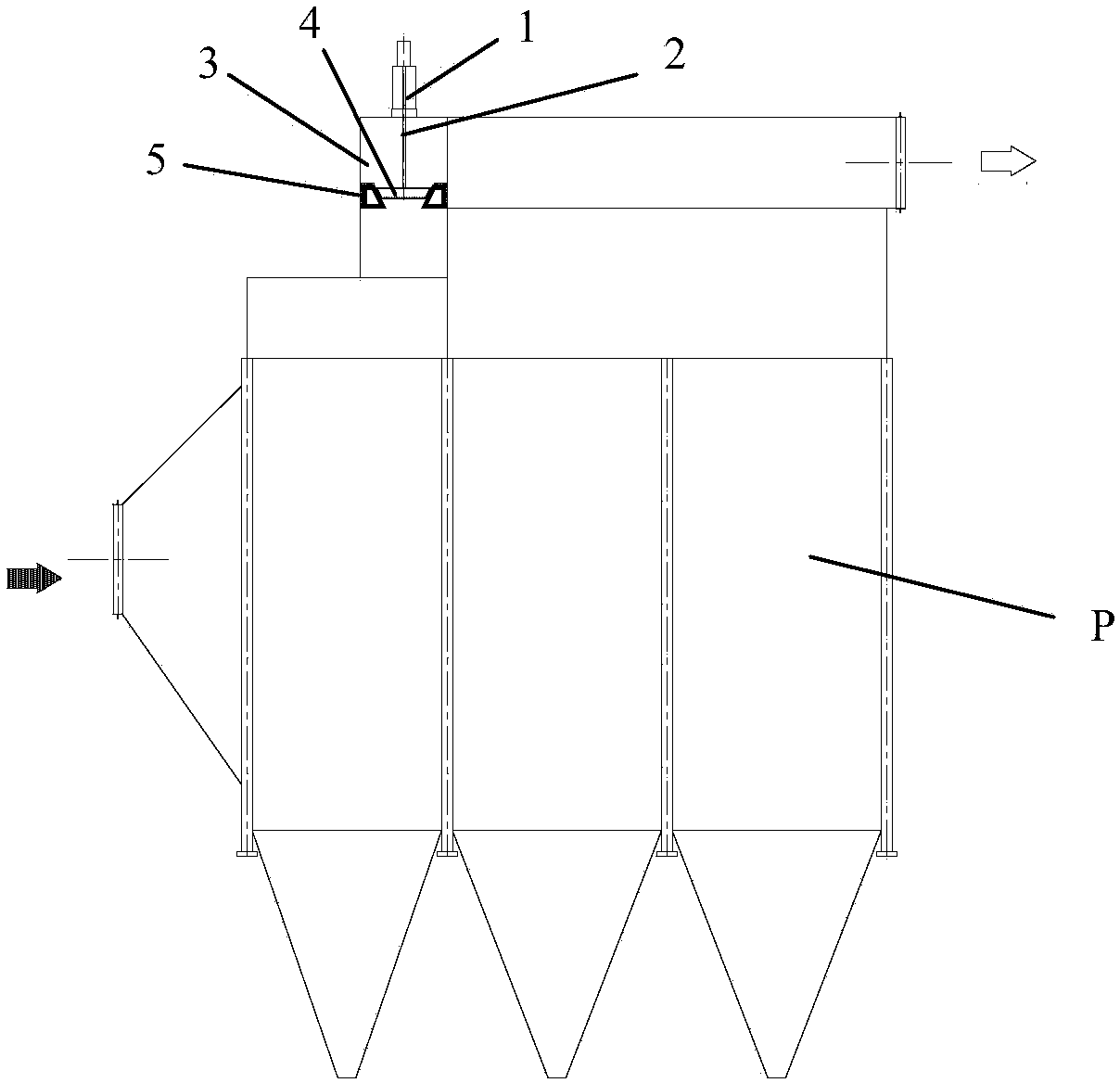

[0019] Such as Figure 1~5 As shown, the embodiment of the present invention is provided with a power unit 1 , a lifting rod 2 , a valve plate 4 and a valve seat 5 . The upper part of the lifting rod 2 is connected with the power unit 1, and the bottom end of the lifting rod 2 is fixedly connected to the top of the valve plate 4. The valve plate 4 and the valve seat 5 adopt an annular cone surface structure, and the outer annular cone surface of the valve plate 4 is in contact with the valve plate. The inner annular cone surface of the seat 5 is sealed and fitted; the valve seat 5 is arranged on the inner side of the inlet of the air duct 3 of the dust collector. exist Figure 1~5 In the figure, the arrow indicates the flue gas; the mark P is the dust collector; the mark A is the sealing surface.

[0020] The taper of the inner annular tapered surface of the valve seat 5 is 10-60°.

[0021] The power device 1 can be a cylinder, and the power device 1 is used to push the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com