Semiconductor device and forming method thereof

A semiconductor and device technology, applied in the field of semiconductor devices and their formation, can solve the problems of easy leakage, low ion concentration, and inability to meet the normal function of the device, and achieve the effect of ensuring current isolation and leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

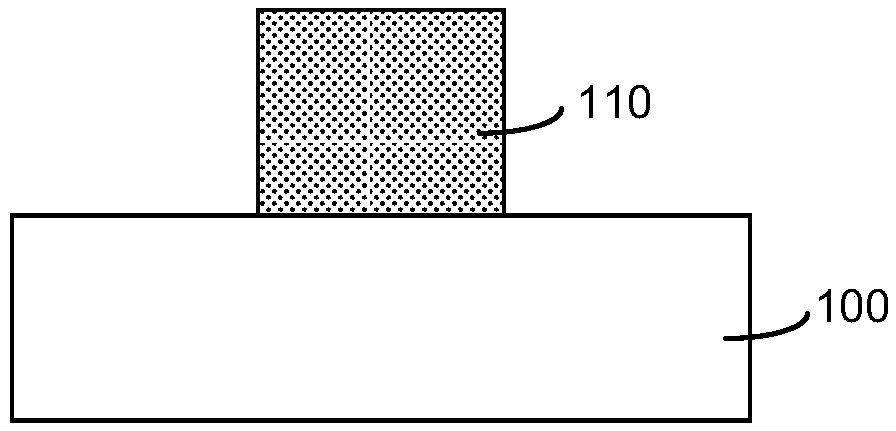

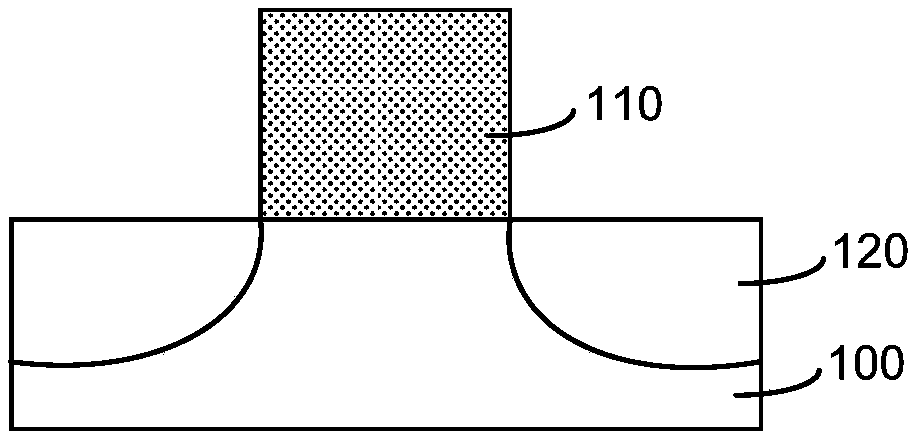

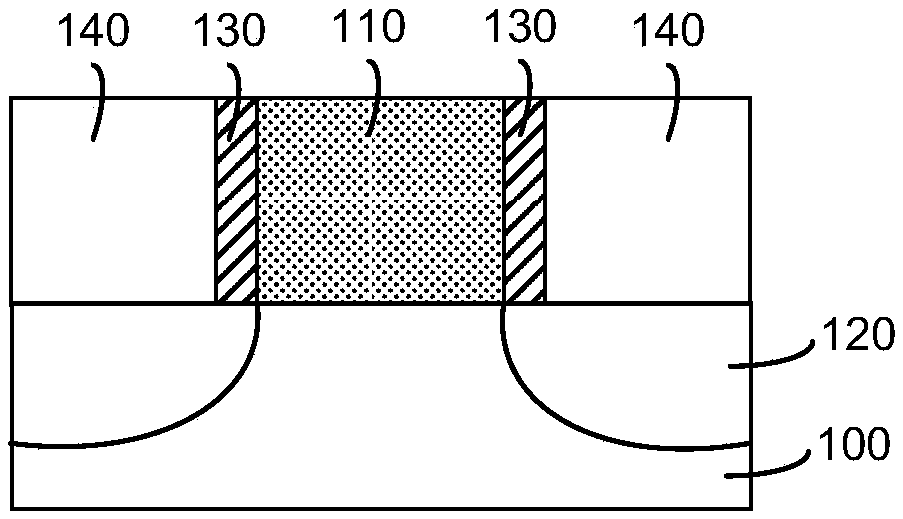

[0031] As mentioned above, in the existing semiconductor devices, there is a problem that the current is easy to leak in the source / drain and the lower part of the channel.

[0032] After research, it is found that the reason for the above problems is that the ion concentration in the lower part of the source / drain is lower than that in the upper part, and the impurity ions in the lower part of the source / drain are easy to diffuse into the channel to form an impurity diffusion region. When a voltage is applied, a current flows between the magazine diffusion regions, causing leakage and reducing the performance of the semiconductor device.

[0033] In order to solve this problem, the present invention provides a method for forming a semiconductor device. A diffusion barrier structure is formed between the lower part of the source / drain and the lower part of the channel, which can effectively avoid leakage and improve the performance of the device.

[0034] Various exemplary emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com