Freeze drying method and accessory equipment

A drying method and freeze-drying technology, which can be used in drying solid materials, lighting and heating equipment, and drying solid materials without heating. , Improve the effect of freeze-drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

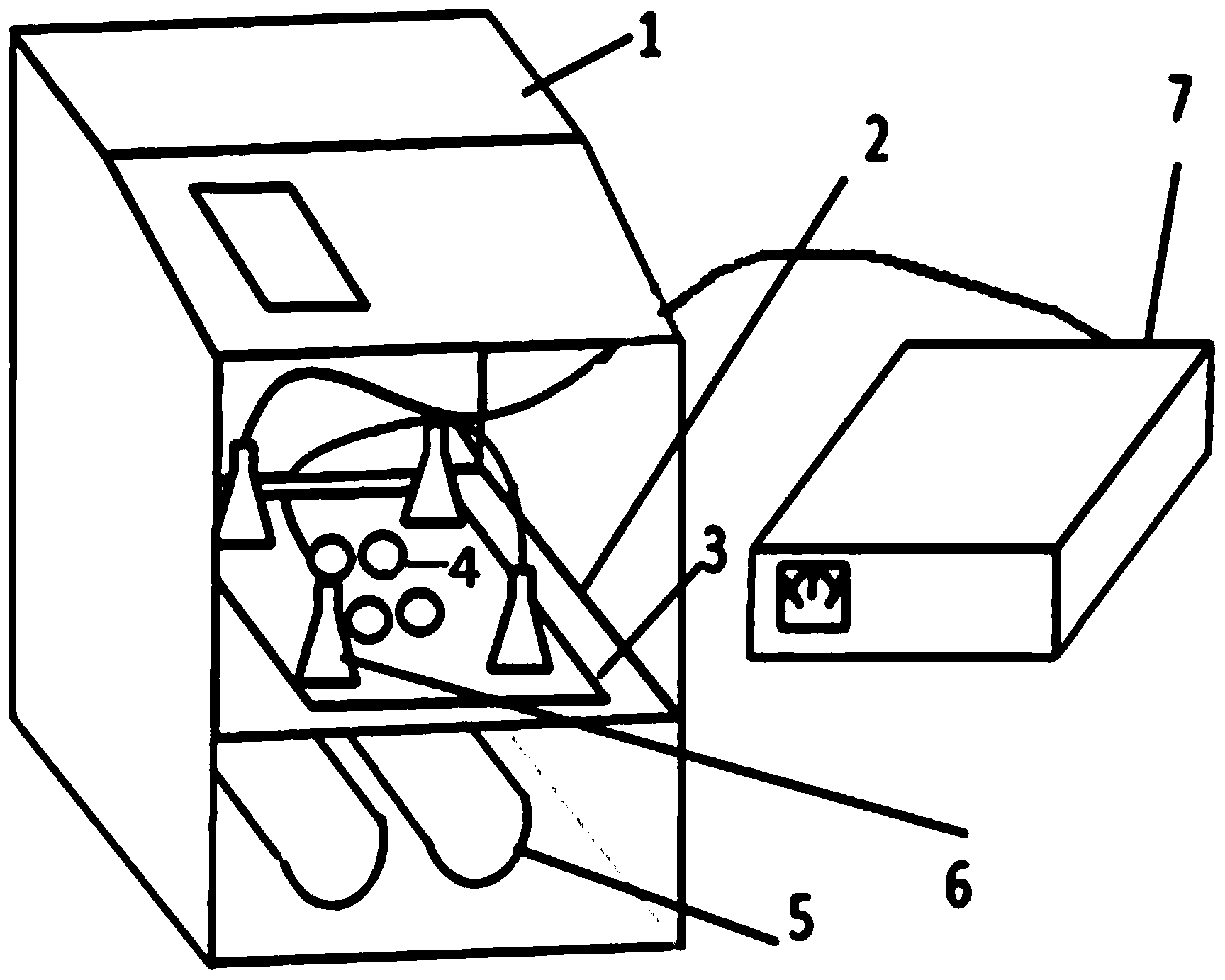

[0028] figure 1 It is a three-dimensional schematic view of the freeze-drying device of the present invention in Embodiment 1, Embodiment 2 and Embodiment 3.

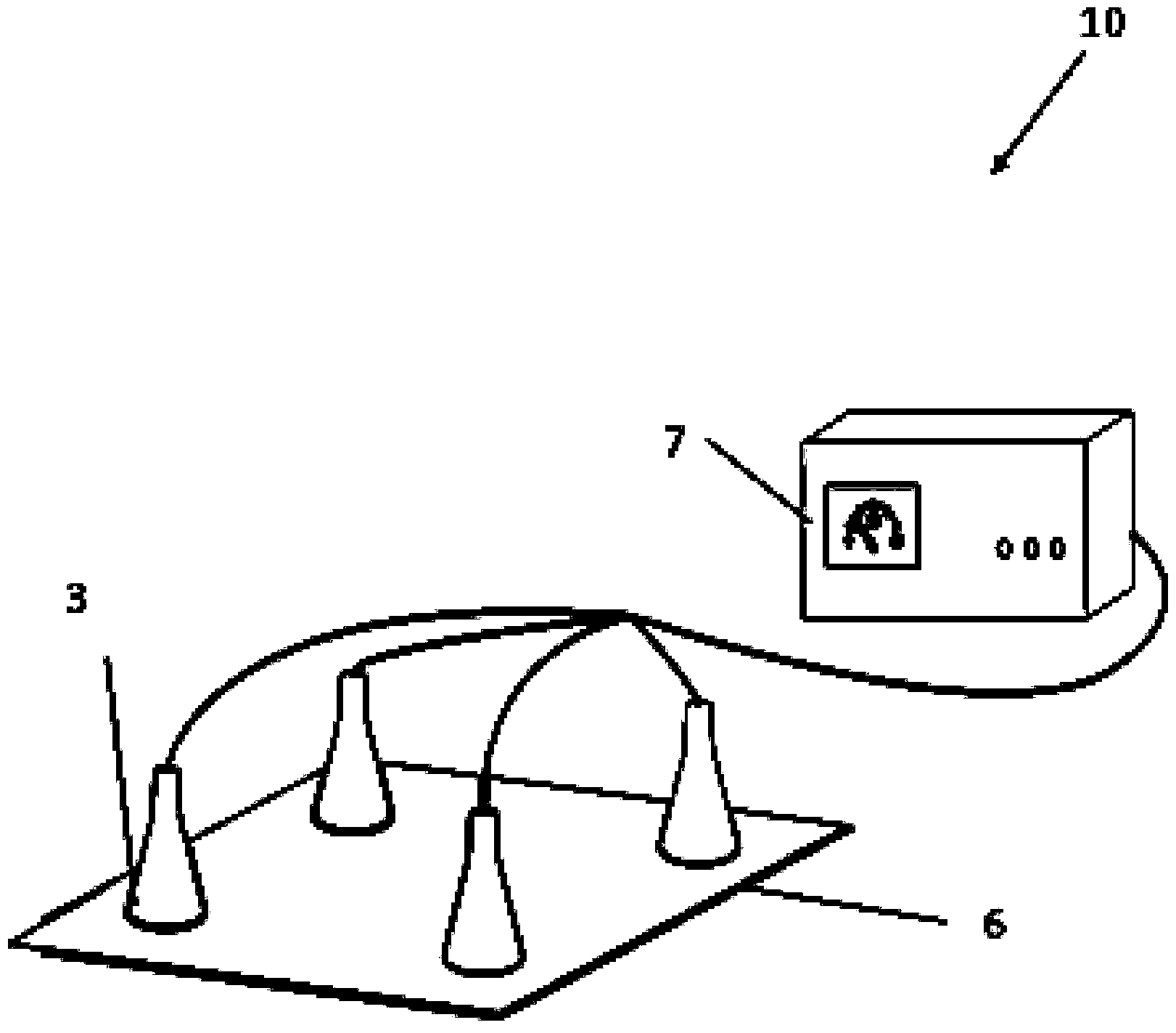

[0029] figure 2 It is a three-dimensional schematic diagram of the freeze-drying supporting equipment of the present invention in Embodiment 1, Embodiment 2 and Embodiment 3.

[0030] Such as figure 1 and figure 2 As shown, the freeze-drying equipment 10 includes: an ultrasonic generator 7 , four ultrasonic vibrators 6 and a flat plate 3 .

[0031] The resonance impedance of the ultrasonic vibrator 6 is 20Ω, the resonance frequency is 28KHz, the diameter of the bottom surface is 59mm, and the height is 68mm. The size of the plate 3 is 200mm*200mm*1.5mm.

[0032] The ultrasonic generator 7 is connected to four ultrasonic vibrators 6 , and the ultrasonic vibrators 6 are uniformly distributed and fixed at four right angles of the plate 3 .

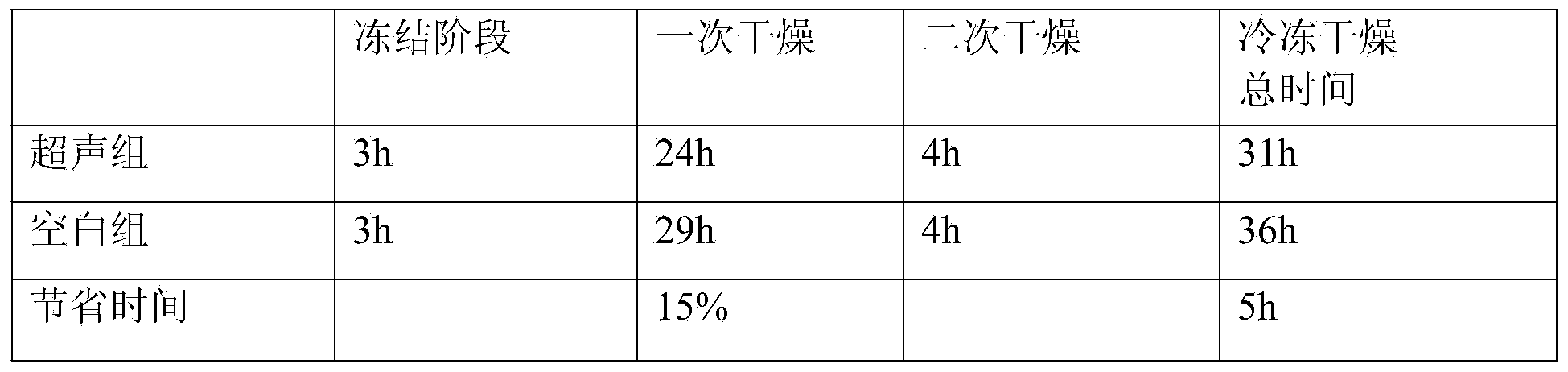

[0033] The freeze-drying method adopted in the present embodiment one comp...

Embodiment 2

[0049]A kind of auxiliary equipment of freeze-drying method, tool is used in conjunction with freeze-drying machine, has the structure identical with embodiment 1.

[0050] The freeze-drying method adopted in the present embodiment two comprises the following steps:

[0051] (1) Peel and slice fresh bananas to obtain banana slices 4 with a diameter of 20 mm and a thickness of 8 mm, and store the apples in a refrigerator at 4° C. for later use.

[0052] (2) Connect the ultrasonic vibrator 6, the ultrasonic generator 7 and the plate 3 according to the same steps as in the first embodiment. Place the plate 3 on the shelf 2 of the freeze dryer 1, turn on the refrigeration function of the freeze dryer 1, set the temperature of the shelf 2 to -40°C, and pre-cool for 2 hours.

[0053] (3) Take out the banana slice 4 from the refrigerator, place it on the center of the four ultrasonic vibrators 6 on the flat plate 3, insert the thermocouple into the geometric center of the banana sli...

Embodiment 3

[0065] A freeze-drying method supporting equipment, used in conjunction with a freeze-drying machine, has the same structure as in Example 1.

[0066] The freeze-drying method adopted in the present embodiment three comprises the following steps:

[0067] (1) Peel and slice fresh apples to obtain apple slices 4 with a diameter of 40 mm and a thickness of 2 mm, and store the apples in a refrigerator at 5° C. for later use.

[0068] (2) Connect the ultrasonic vibrator 6, the ultrasonic generator 7 and the plate 3 according to the same steps as in the first embodiment. Place the plate 3 on the shelf 2 of the freeze dryer 1, turn on the refrigeration function of the freeze dryer 1, set the temperature of the shelf 2 to -50°C, and pre-cool for 4 hours.

[0069] (3) Take the apple slice 4 out of the refrigerator, place it at the center of the four ultrasonic vibrators 6 on the flat panel 3, insert the thermocouple into the geometric center of the apple slice 4; keep the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap