Inner chamfer detection device and method

A detection device and chamfering technology, which is applied in the detection field, can solve problems such as inability to perform detection, limited space of the shadow instrument, and inaccurate detection results, etc., and achieve the effect of simple structure, no space restriction, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

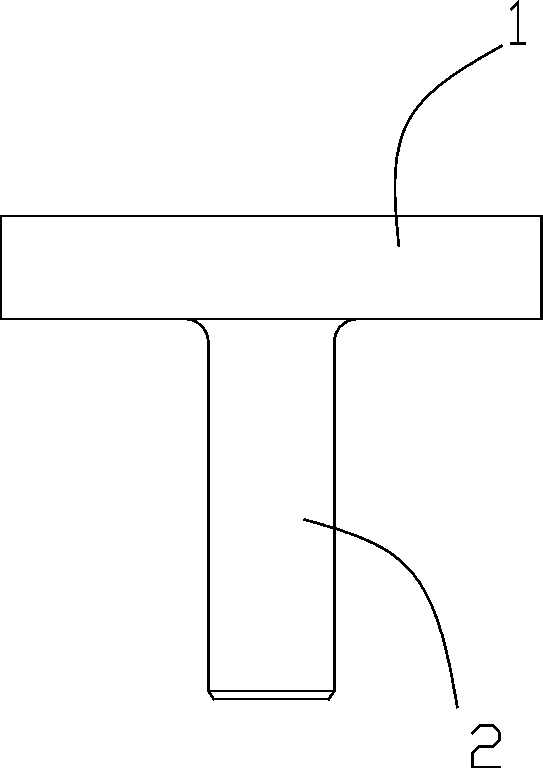

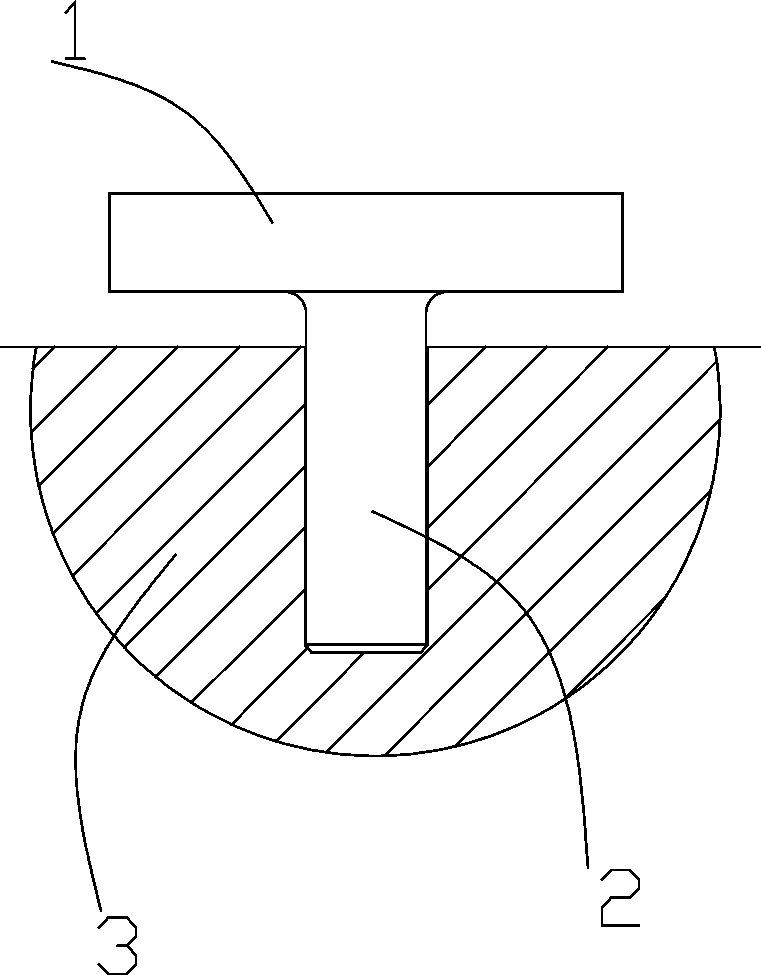

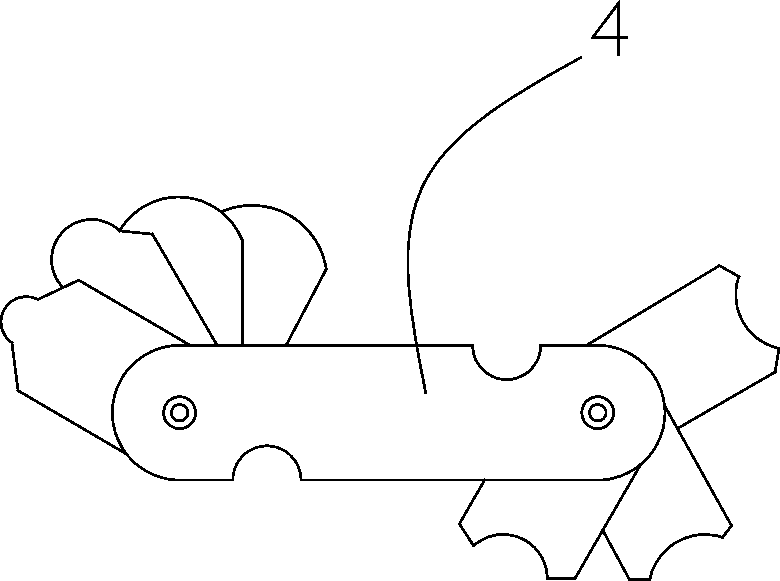

[0012] see Figure 1 to Figure 3 As shown, a kind of internal chamfering detection device comprises a handle 1, on which a cylindrical measuring rod 2 made of metal tin is arranged, and the measuring rod 2 is inserted into the recess of the part 3 to be detected and Fits inside chamfers; fillet gauge 4 also included. The present invention adopts metal tin with soft texture, low melting point and strong plasticity at normal temperature as the measuring rod 2, which is inserted into the depression of the part to be detected, so that the front end of the measuring rod is pressed into an outer chamfer with consistent inner chamfering, The outer chamfer is then directly measured without being limited by the variation of the aperture.

[0013] The aforementioned inner chamfers include inner chamfers and inner rounded corners.

[0014] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com