Detection device for detecting deformation of quartz boat

A detection device, quartz technology, applied in the direction of mechanical solid deformation measurement, etc., can solve the problems of silicon wafer or quartz boat damage, card slots 21 are no longer arranged in parallel, easy to deform, etc., to achieve the effect of improving production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

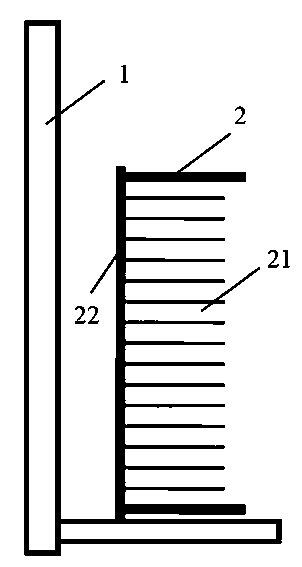

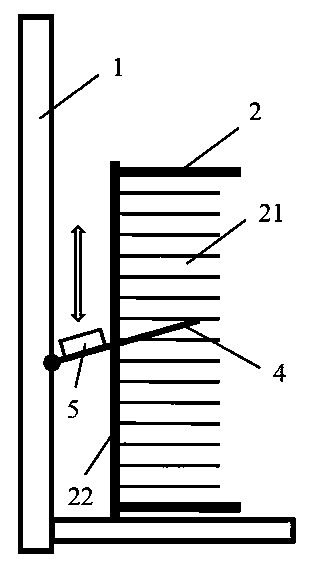

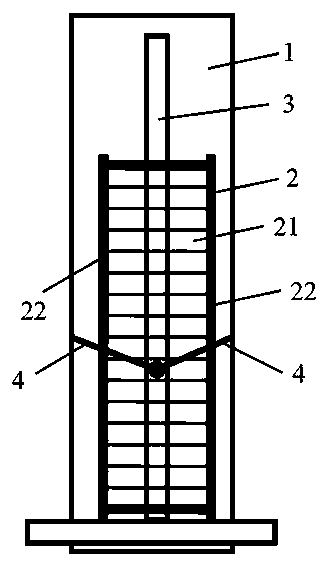

[0012] The following combination figure 2 with image 3 , the present invention is described in detail through preferred specific embodiments.

[0013] Such as figure 2 with image 3 As shown, the detection device for detecting the deformation of the quartz boat provided by the present invention is installed on the workbench 1 in the atmospheric pressure furnace, and the detection device includes: a transmission shaft 3 vertically arranged on the workbench 1, which can be along The side wall of the workbench 1 moves up and down; at least one pointer 4 is arranged between the transmission shaft 3 and the quartz boat 2, one end of the pointer 4 is fixedly arranged on the transmission shaft 3, and the other end is connected to the quartz boat 2 One of the columns 22 is in contact; and the dial 5 is arranged on the pointer 4 .

[0014] Such as image 3 As shown, in this embodiment, the detection device includes two pointers 4 arranged at an angle, one end of each pointer 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com