Blade abrasion evaluation method of KR desulfuration paddle agitator

A blade wear and agitator technology, which is applied in the field of blade wear evaluation of KR desulfurization paddle agitators, can solve the problems of unstable desulfurization effect, unfavorable desulfurization operation stably and orderly, and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

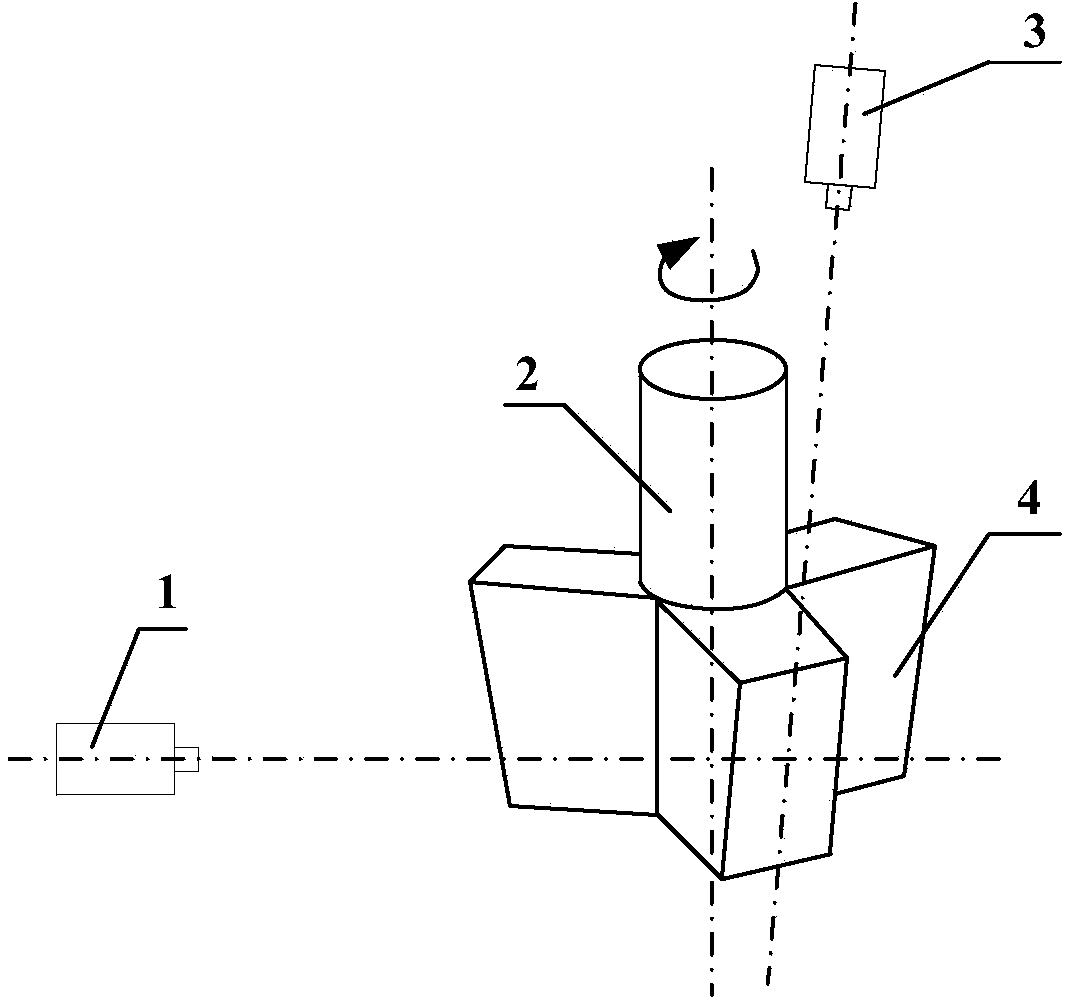

[0062] A blade wear evaluation method for a paddle agitator used in KR desulfurization. The specific steps of the evaluation method are as follows: Figure 5 Shown:

[0063] The first step, the setting of blade wear evaluation position

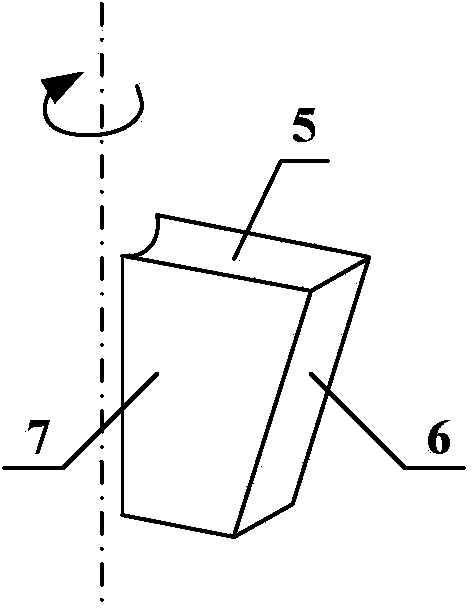

[0064] The paddle agitator 2 blades to be evaluated in this embodiment are uniformly arranged for KR desulfurization, and the number of blades 4 is 3. The surface of each blade 4 consists of the upper end surface 5 of the blade, the lower end surface of the blade opposite to the upper end surface 5 of the blade, The blade force-bearing side 7, the other side opposite to the blade force-bearing side 7 and the blade outer end surface 6 are composed.

[0065] The blade wear evaluation position is: the plane determined by the centroid of the blade 4 is on the same plane as the lens centerline of the first industrial camera 1, and the circle formed by the rotation of the centroid of the blade 4 is tangent to the lens centerline of the first indus...

Embodiment 2

[0104] A blade wear evaluation method for a paddle agitator used in KR desulfurization. The specific steps of the evaluation method are as follows: Figure 5 Shown:

[0105] The first step, with the first step of embodiment 1;

[0106] Second step, with embodiment 1 second step;

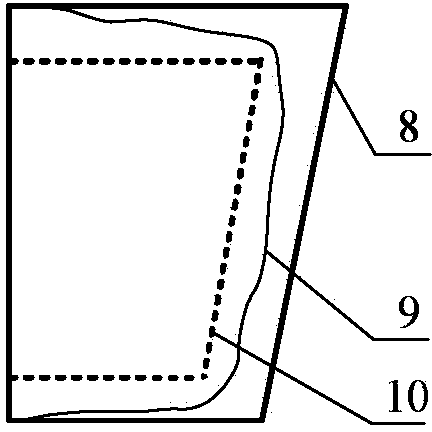

[0107] The third step is to use the manual adjustment method to determine the service limit shape of the blade 4 of the KR desulfurization paddle agitator 2 that is worn out to the point of being unusable:

[0108] Take the midpoint of the edge of the force-bearing side 7 of the blade close to and parallel to the axis line of the paddle agitator 2 for KR desulfurization as the reduced reference point; for the force-bearing side 7 of the blade, follow the initial standard shape 8: use limit shape 10 The side length ratio of the corresponding side is 1:k for shrinking to obtain the service limit profile 10 of the stressed side surface 7 of the blade.

[0109] Take the midpoint of the line connectin...

Embodiment 3

[0124] A blade wear evaluation method for a paddle agitator used in KR desulfurization. The specific steps of the evaluation method are as follows: Figure 5 Shown:

[0125] The first step is except that the quantity of blade 4 is 4, all the other are with the first step of embodiment 1;

[0126] Second step, with embodiment 1 second step;

[0127] The 3rd step except following parameter, all the other are with the 3rd step of embodiment 2;

[0128] Wherein: k=the axial length of the unused blade 4 after removing 65% of the thickness of the surface refractory material layer / the axial length of the unused blade 4 .

[0129] The fourth step, first predetermine the wear replacement value W1 and the wear repair value W2 of the blade 4 during use. In this embodiment, determine the wear replacement value W1=0.85 and the wear repair value W2=0.43, and then evaluate the blade 4 during use. wear condition;

[0130] S4-1 is the same as S4-1 of Embodiment 1.

[0131] S4-2 is the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com