Method and device for simulating axial interaction between undersea pipe system structure and seabed soil body

A seabed soil and axial technology, which is used in the fields of marine soil mechanics, submarine pipeline engineering, and offshore oil and gas engineering, can solve the problem of insufficient pore water pressure dissipation, reduce the anti-slip ability of the pipeline, and reduce the effective contact stress between the pipeline and soil particles, etc. problems, to achieve the effect of reducing interference and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

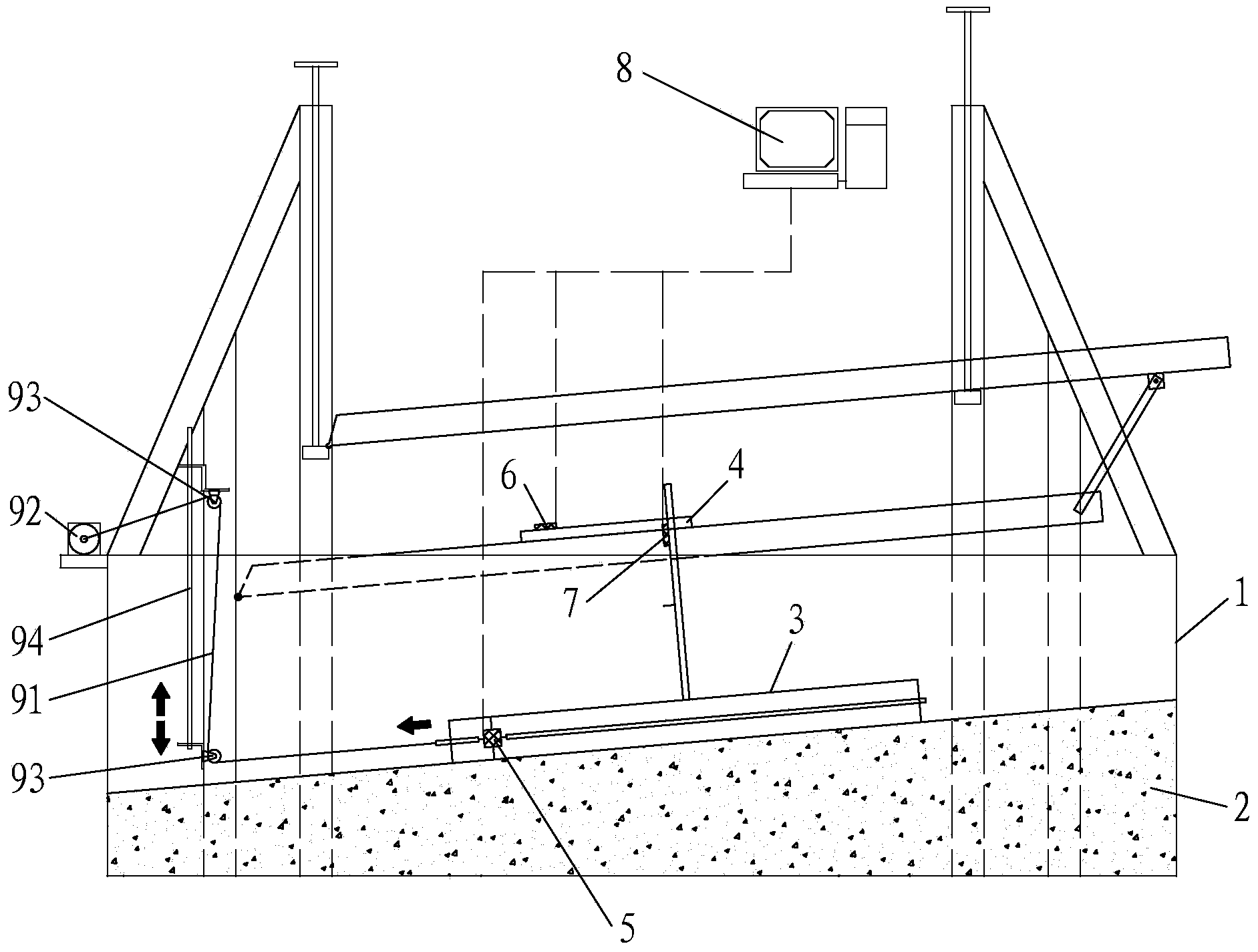

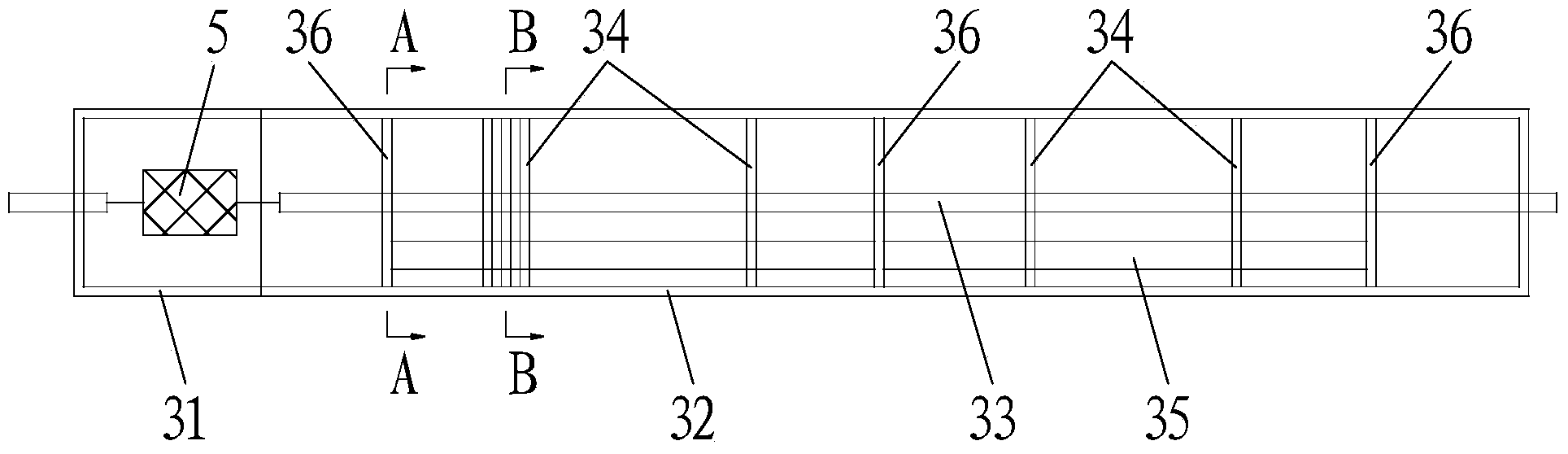

[0031] refer to Figure 1-7 , the method for simulating the axial interaction between the subsea piping system structure and the seabed soil in this embodiment includes the following steps: (1) using separate traction pipe heads 31 and pipe test sections 32 to movably splice model pipes 3 , Weight the model pipe 3 as required, then install a tension sensor 5 to measure its axial sliding resistance in the model pipe 3, and fix waterproof sandpaper with required roughness on the surface of the model pipe 3; (2) on the transparent or side wall A simulated seabed 2 is manufactured in the water tank 1 with an observation window; (3) A guide and restraint device 4 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com