High-pressure servo dynamic true triaxial testing machine

A true triaxial, testing machine technology, applied in the field of rock mechanics and rock engineering research, can solve the problems of insufficient rigidity, high cost, inability to disturb, etc., and achieves stable applied load range, large applied load range, and low experimental cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

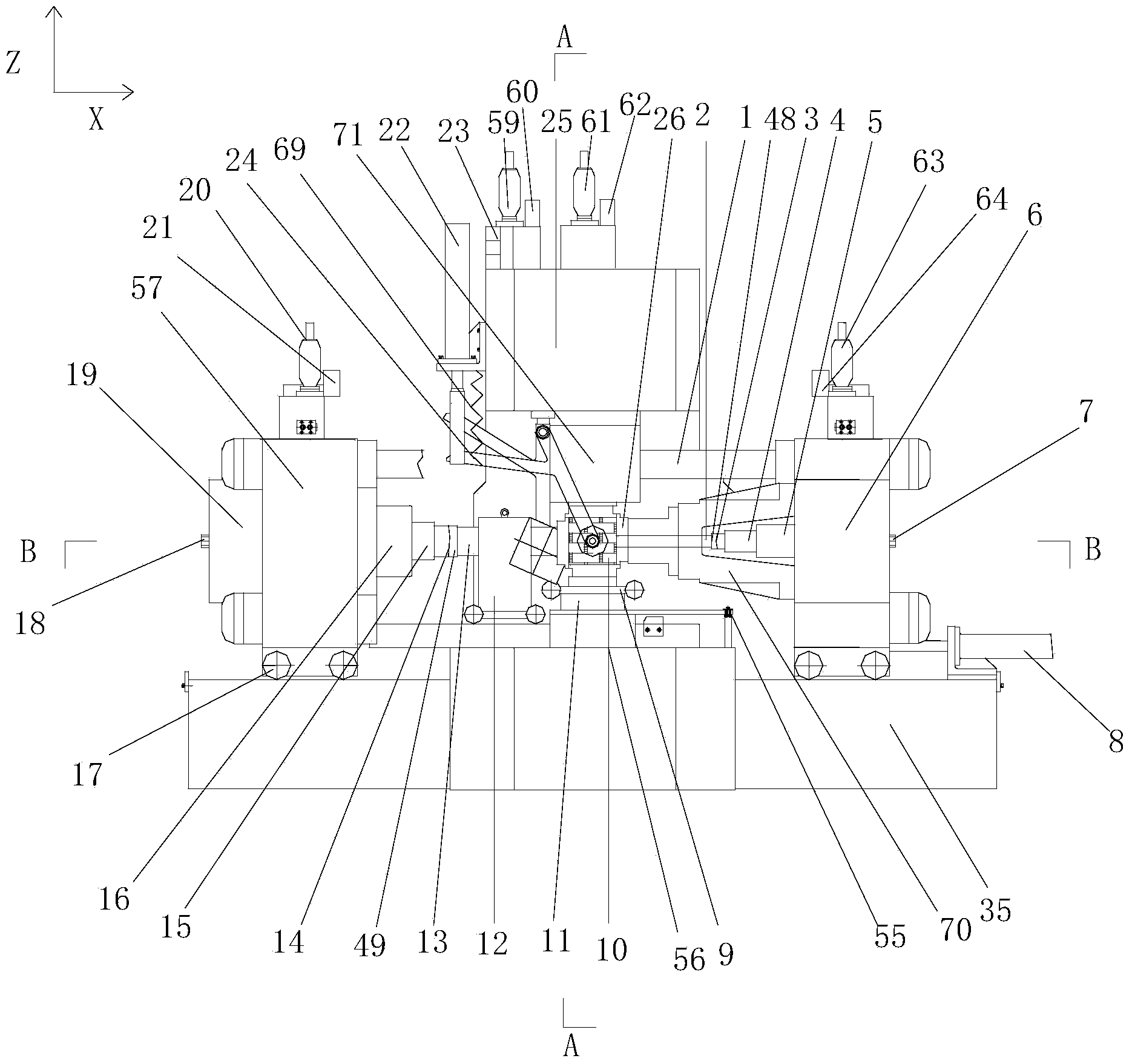

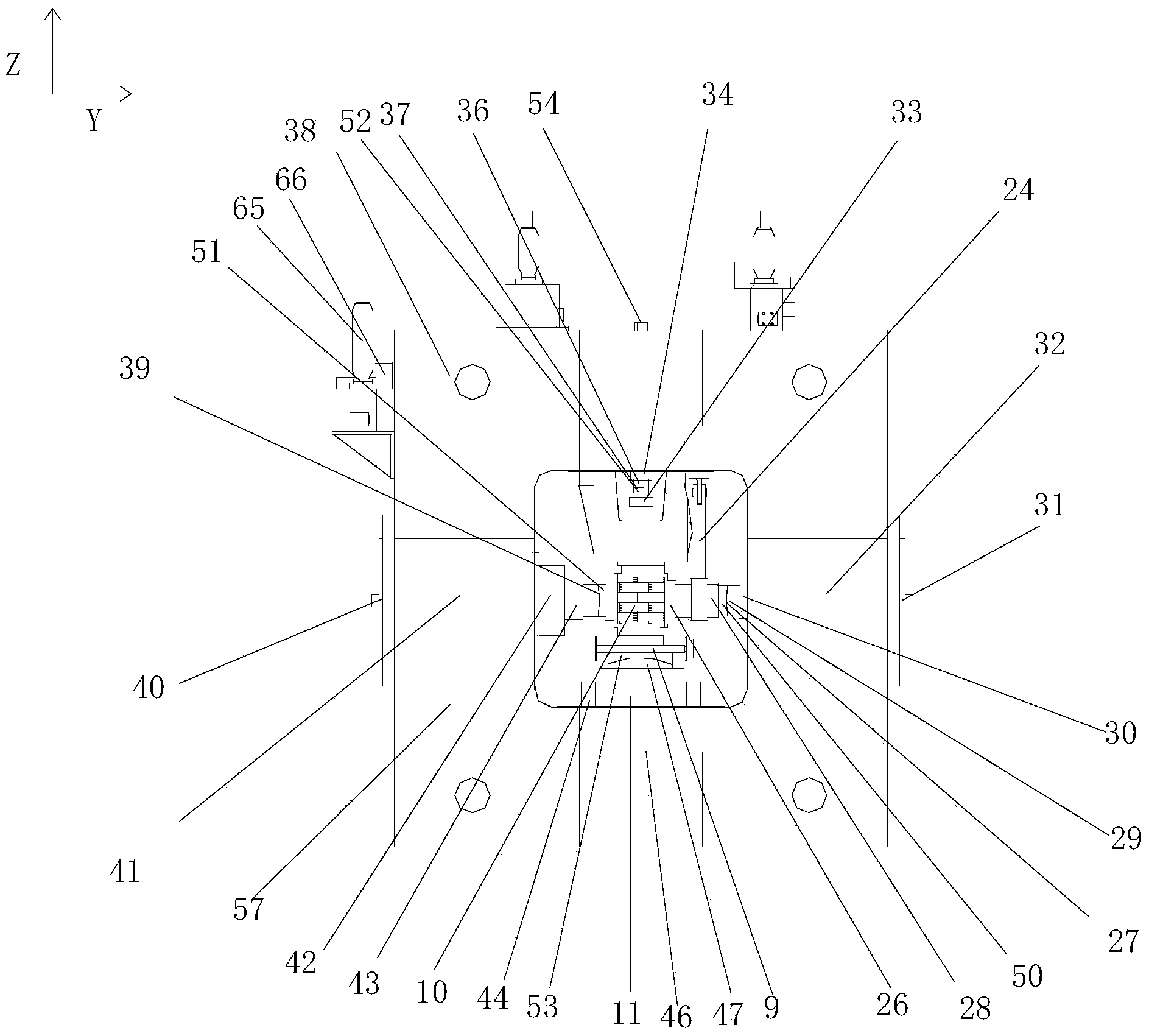

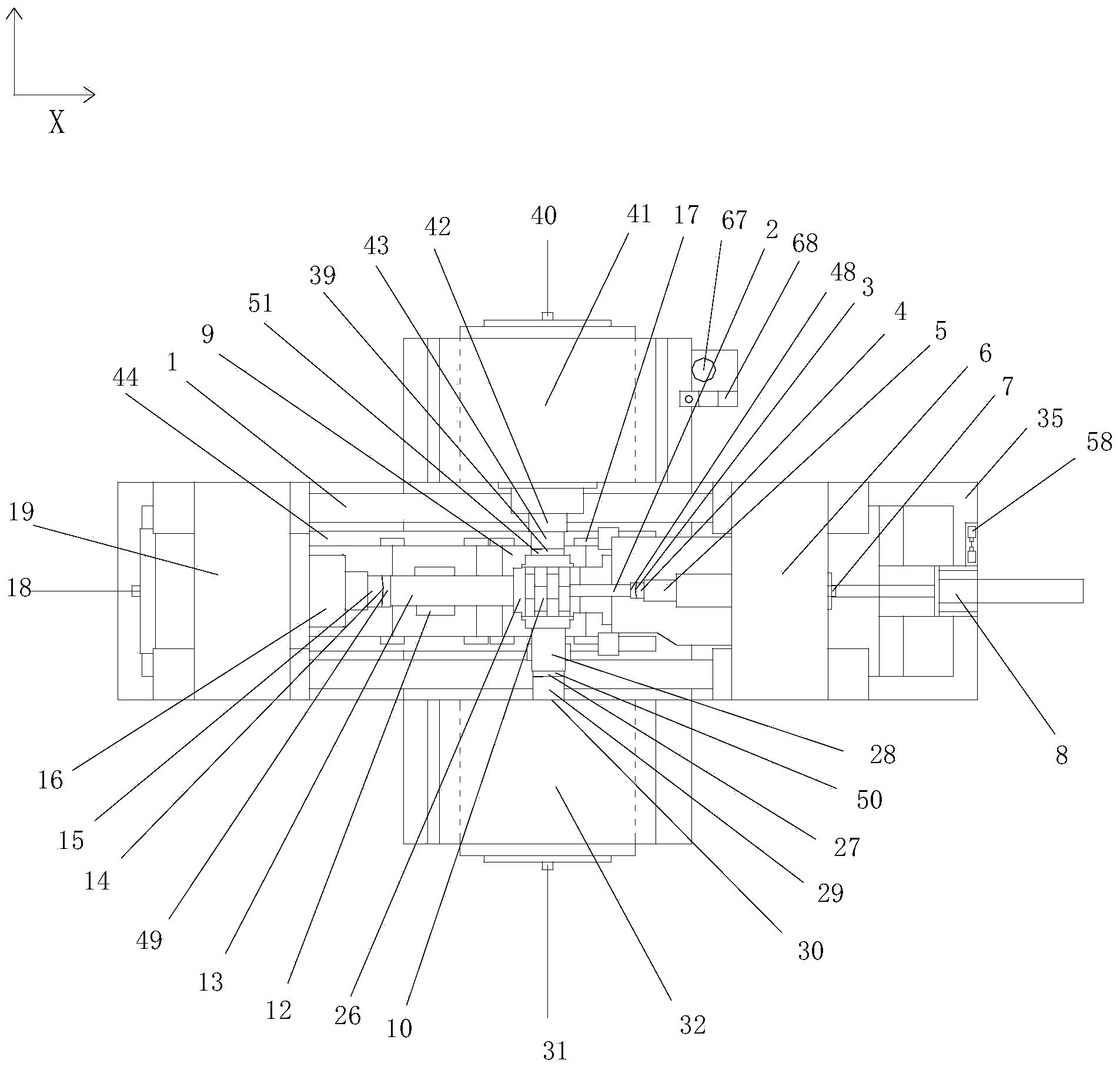

Method used

Image

Examples

example

[0053] The applicable sample size of the present invention is variable, and the sample size range: 200mm~50mm×200mm~50mm×200mm~50mm various combination specifications, and the corresponding indenter fixture 26 is configured. The size can be used for true triaxial tests of various sizes. The displacement sensor and the acquisition system cooperate to collect the deformation of six surfaces at the same time by connecting to the computer, and then collect the pressure information through the force sensor, and then connect the computer through the force collector to obtain any The stress-strain curve at each moment.

[0054] In the above technical solution, it also includes a displacement collector, and the signal output end of each displacement sensor is connected to the computer through the displacement collector. Displacement sensors measure the deformation of the six sides of the test piece and record it automatically. The first X-direction disturbance cylinder 6 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com