Tool running state reliability evaluation method based on EMD

A technology of operating status and reliability, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of accurate evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

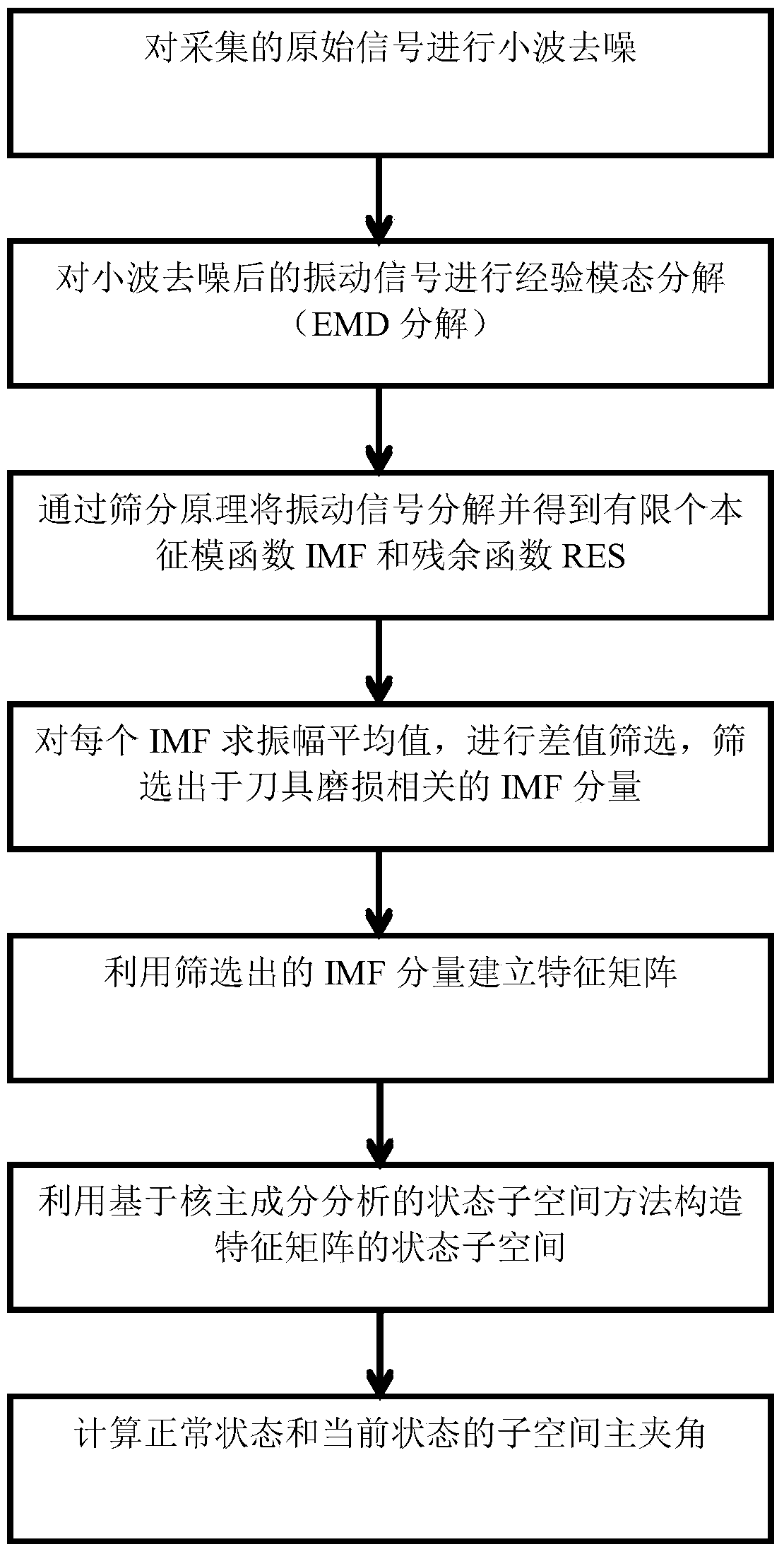

[0041] The object tool of this embodiment is a milling cutter, and the method for evaluating the reliability of the operating state of the tool based on EMD decomposition is specifically as follows:

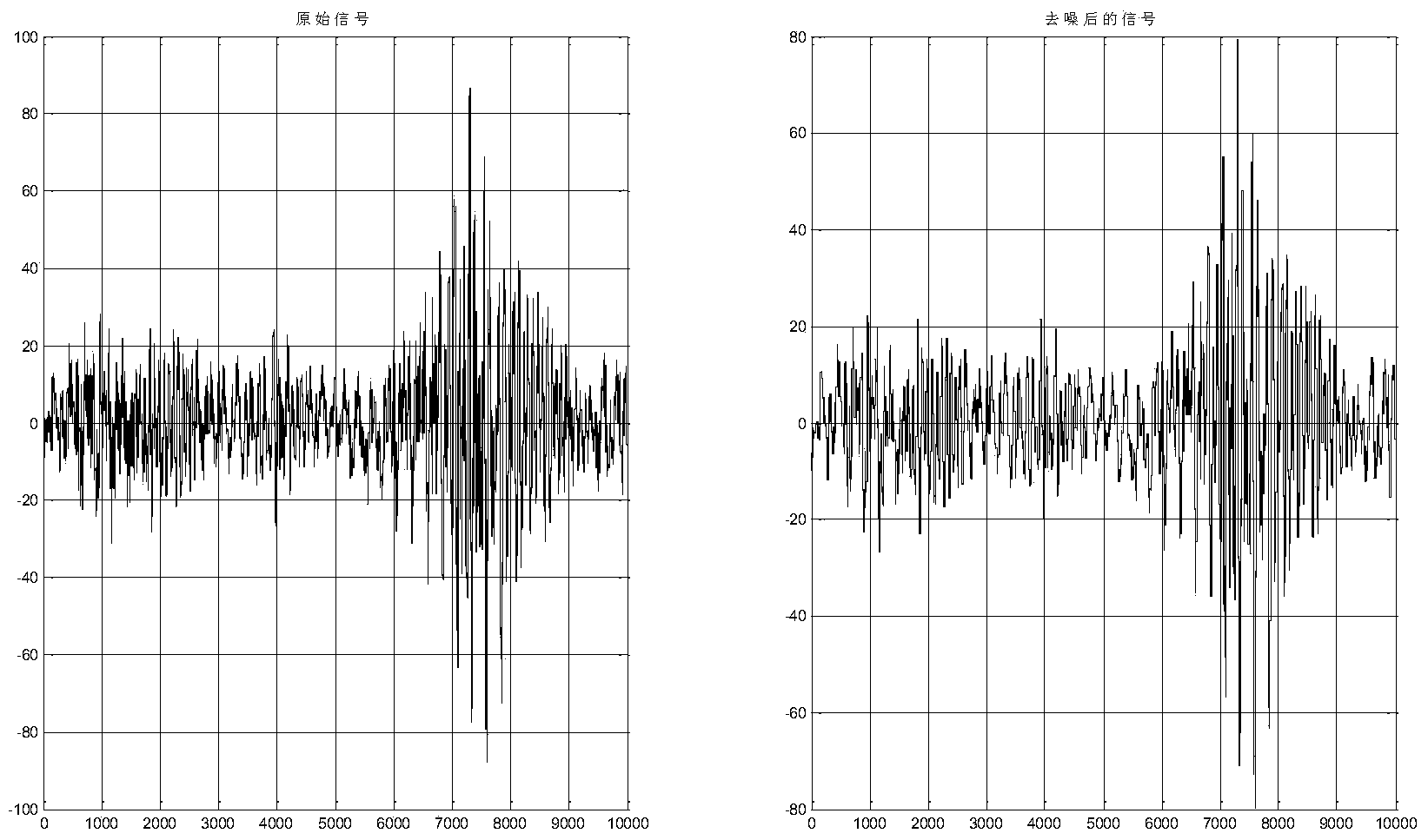

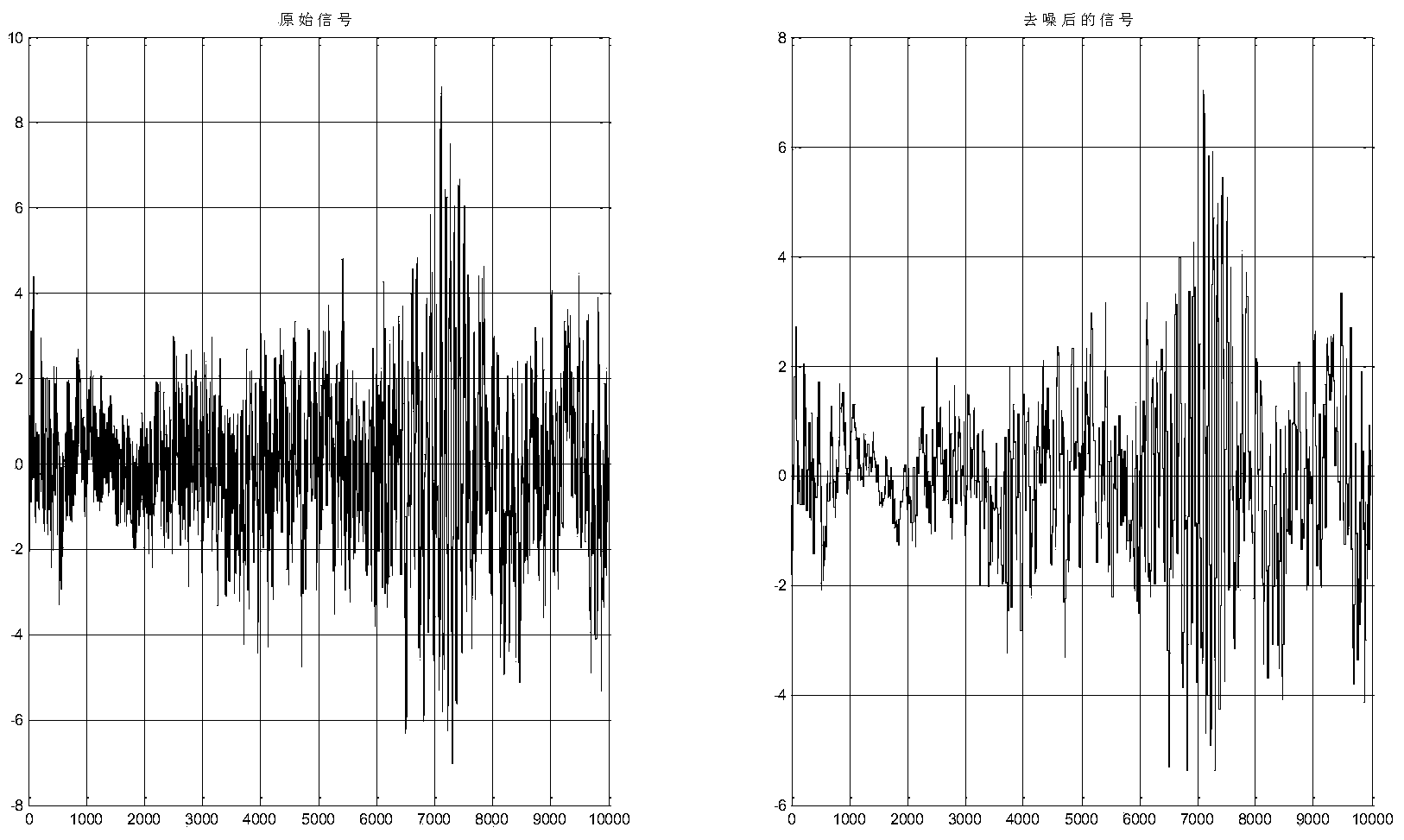

[0042] Step 1: Collect several state signals of the same type of tool in three time periods during operation, including vibration signals, acoustic emission signals, and force signals. Three axial signals, and ignore the signal along the tool axis in the force signal (the signal is not significant), so a total of six state signals are obtained; the three time periods correspond to the initial wear, normal wear and severe wear of the tool respectively; The sampling time is the same for the three time segments.

[0043] In the actual process, the cutting parameters of the milling machine are respectively set, that is, the spindle speed, the feed speed, and the depth of cut. In this embodiment, only the cutting parameters are: spindle speed V=800r / min, feed speed f=12.5mm / min, cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com