Automatic steel plate surface defect recognition method based on case-based reasoning

An automatic identification and case technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems of low recognition accuracy, achieve the effect of improving product quality, improving processing efficiency, and improving production operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

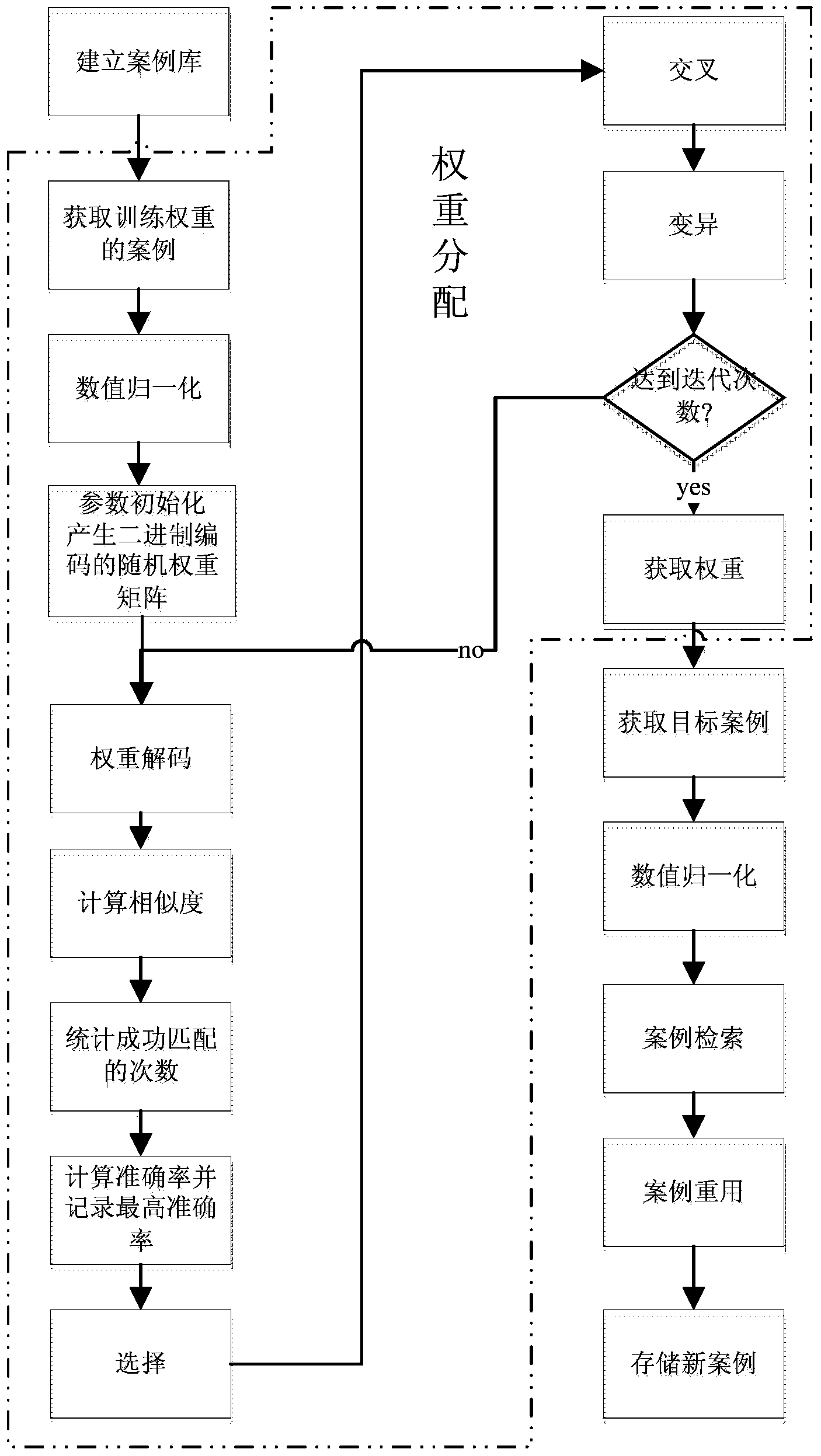

[0070] The present invention obtains an automatic recognition method for steel plate surface defects. The method uses case reasoning technology to establish a case reasoning recognition model through the establishment of case database, weight distribution, case retrieval, case reuse and case storage, and realizes the recognition algorithm to achieve The purpose of identifying defect types through the numerical changes of characteristic variables;

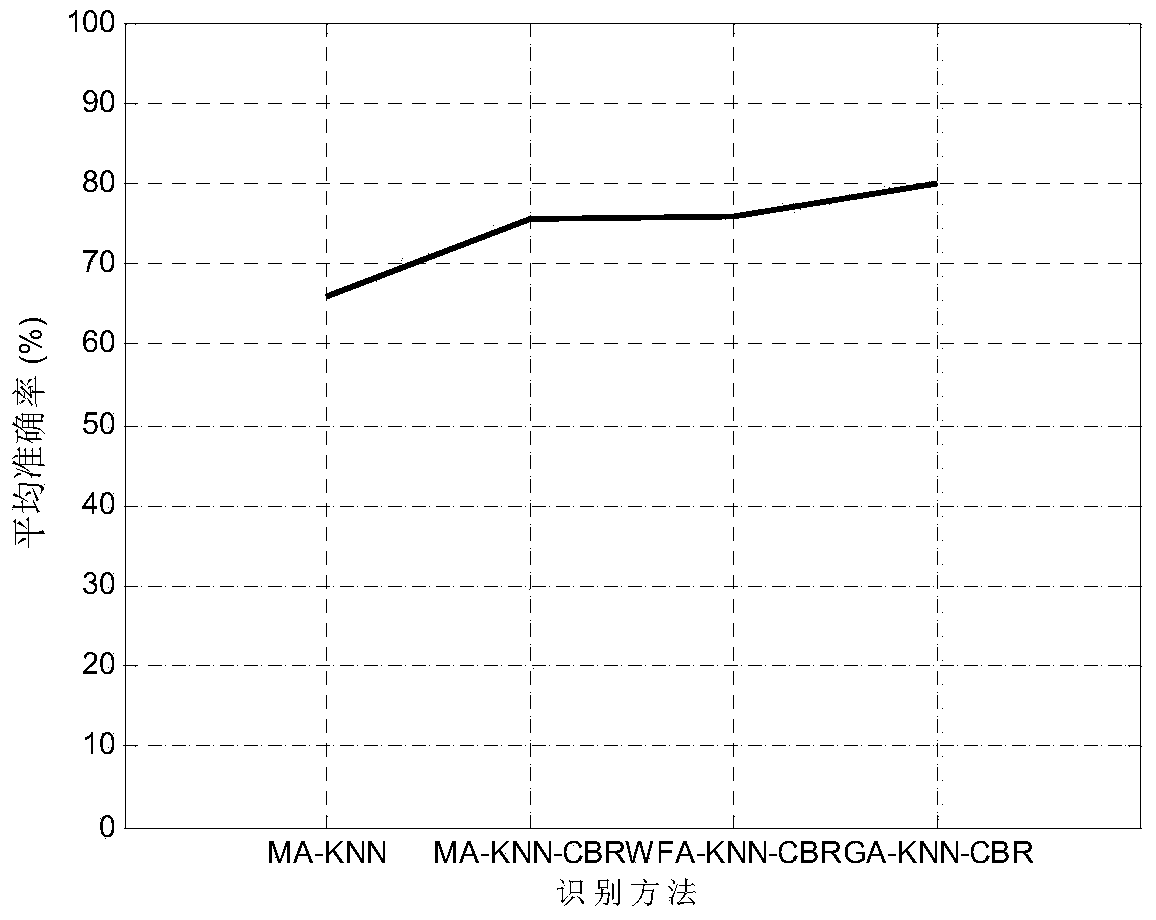

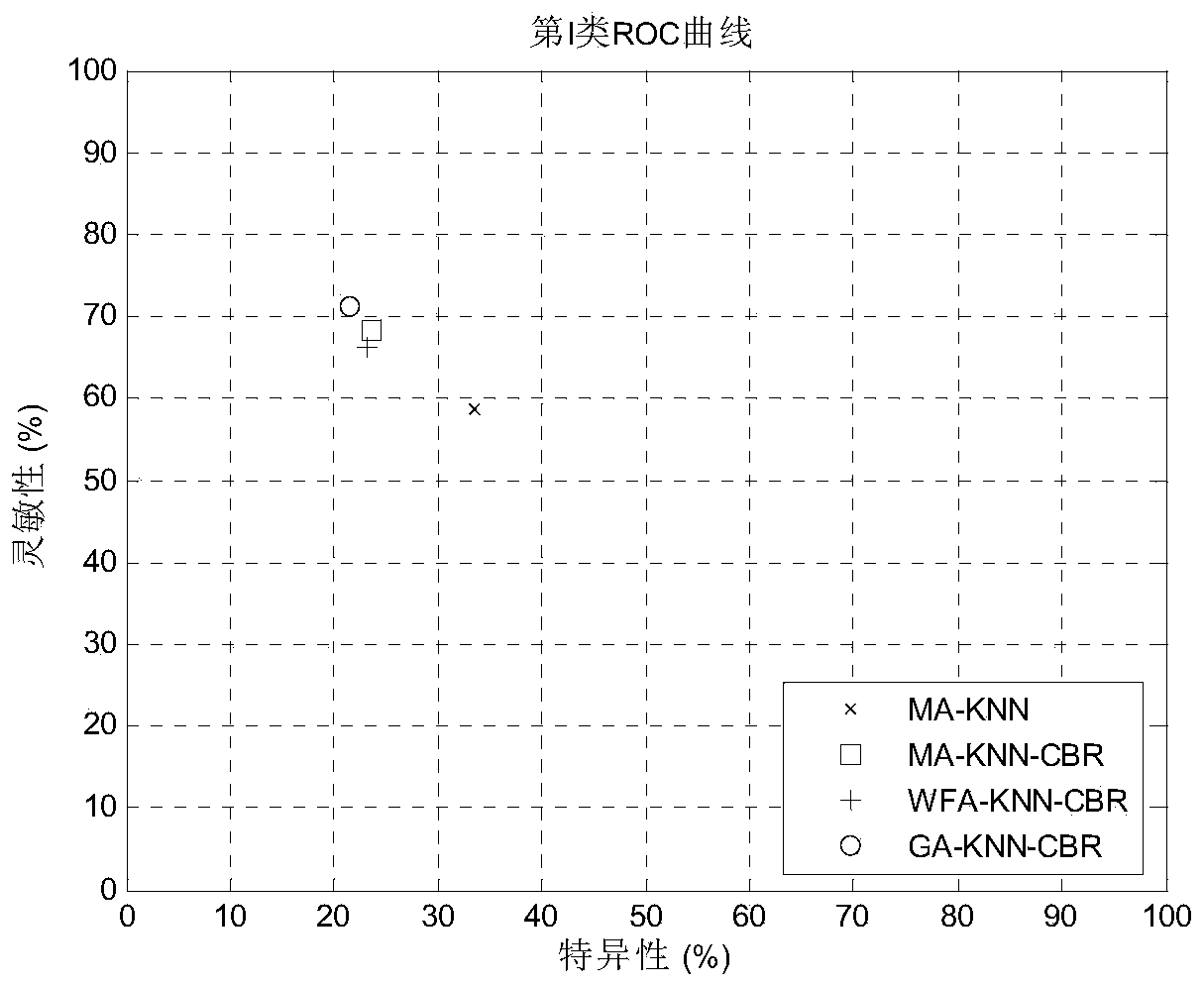

[0071]The experimental data comes from the steel plate characteristic variable parameters and annual reports of defect types of a steel plant; the experimental sample is 1941 sets of data, and all 1941 sets of data samples are divided into two parts: 1746 sets of data are used as source cases, and the remaining 195 sets of data are used as targets case;

[0072] Combine below figure 1 The specific implementation will be further described.

[0073] 1. an automatic identification method of steel plate surface defect based on case re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com