A portable combined motor assembly tool

A combined and sub-frame technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of bulky, non-portable, and poor flexibility of tooling, and achieve small size, ensure attendance, and reduce weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Describe the present invention below in conjunction with specific embodiment:

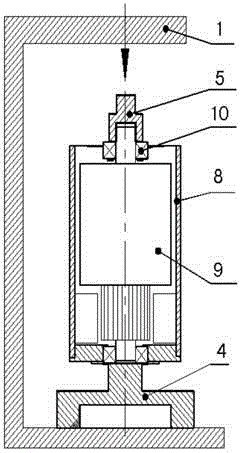

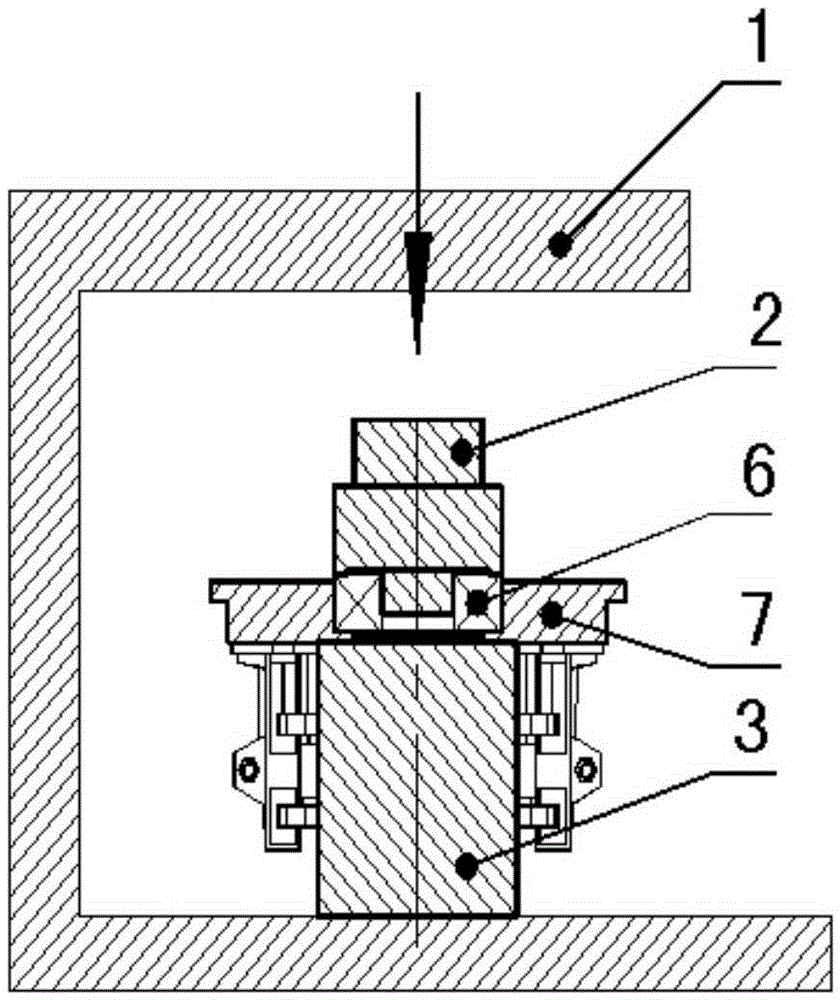

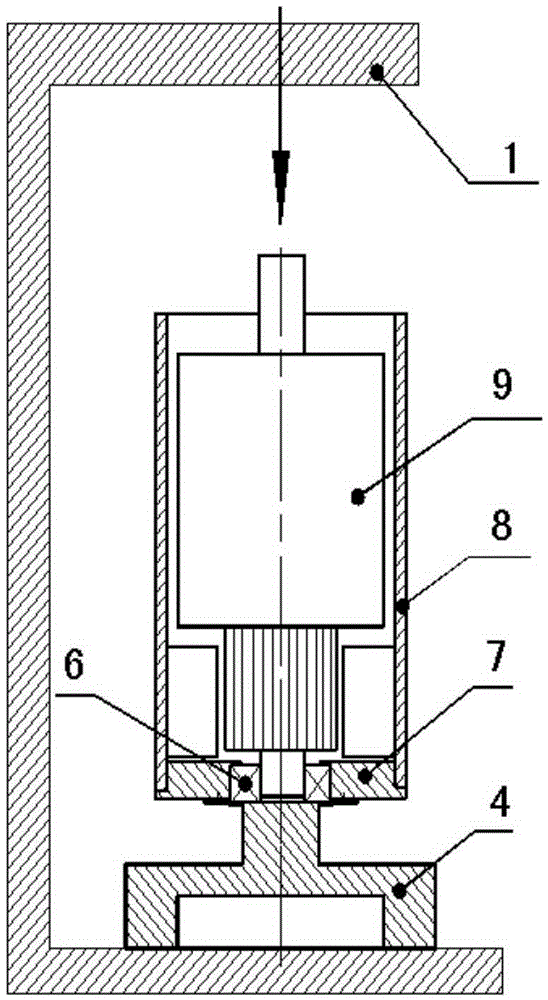

[0039] This embodiment is to provide a set of portable combined tooling to replace bulky equipment and tooling such as a manual press, and complete the motor assembly work through the combination of three different types of tooling.

[0040] Such as Figure 4 to Figure 10 As shown, the portable combined motor assembly tool in this embodiment includes a drop frame 11, a pair of pull rods 12, a hollow commutator end bearing pressure head 13, a pad 14, a bottom plate 15, a pair of support rods 16 and a hollow drive end Bearing head 17.

[0041] The falling subrack is the force device in the tooling, which is composed of a beam, a screw and a screw head; the screw passes through the middle of the beam and is threadedly matched with the beam, and the screw head is fixed on one end of the screw, and the screw head is coaxial with the screw. The other end of the screw rod is fixed with a rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com