Sealing device of driving section

A technology of sealing device and driving part, which is applied to lighting and heating equipment, furnace components, furnace types, etc., can solve the problems of generating equipment investment, reducing driving efficiency of screw feeders, and short service life, and achieving the effect of restraining wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

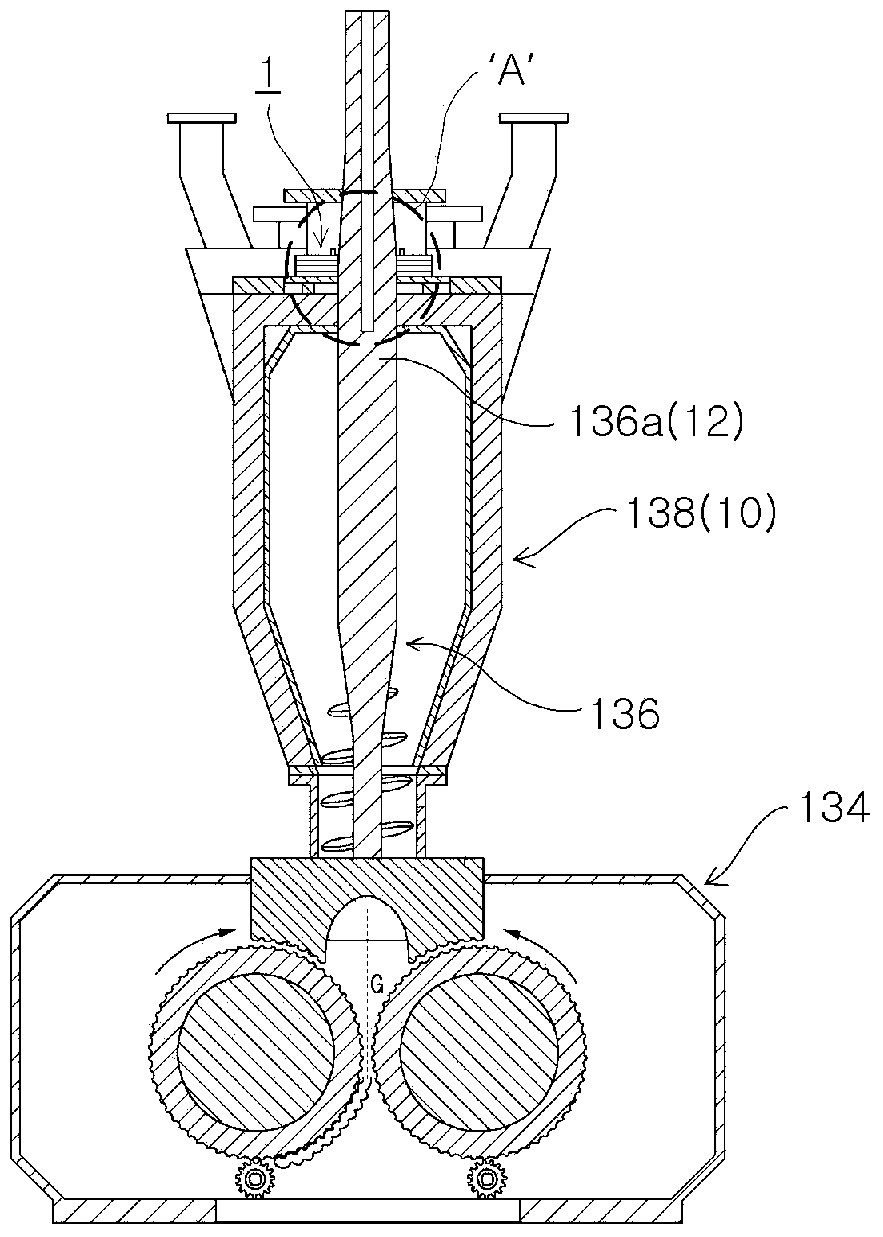

[0043] Hereinafter, the present invention will be described in detail with reference to the drawings.

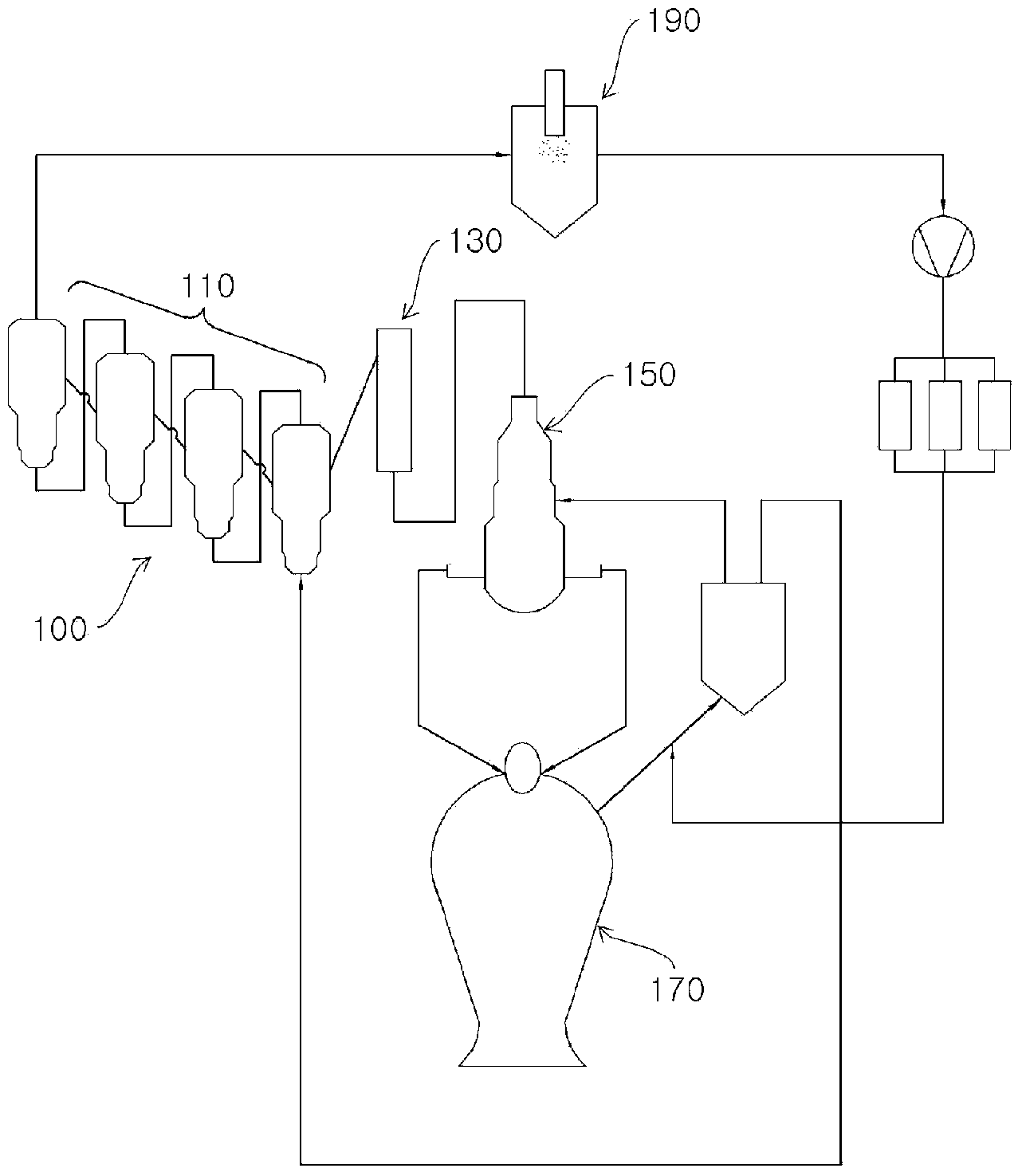

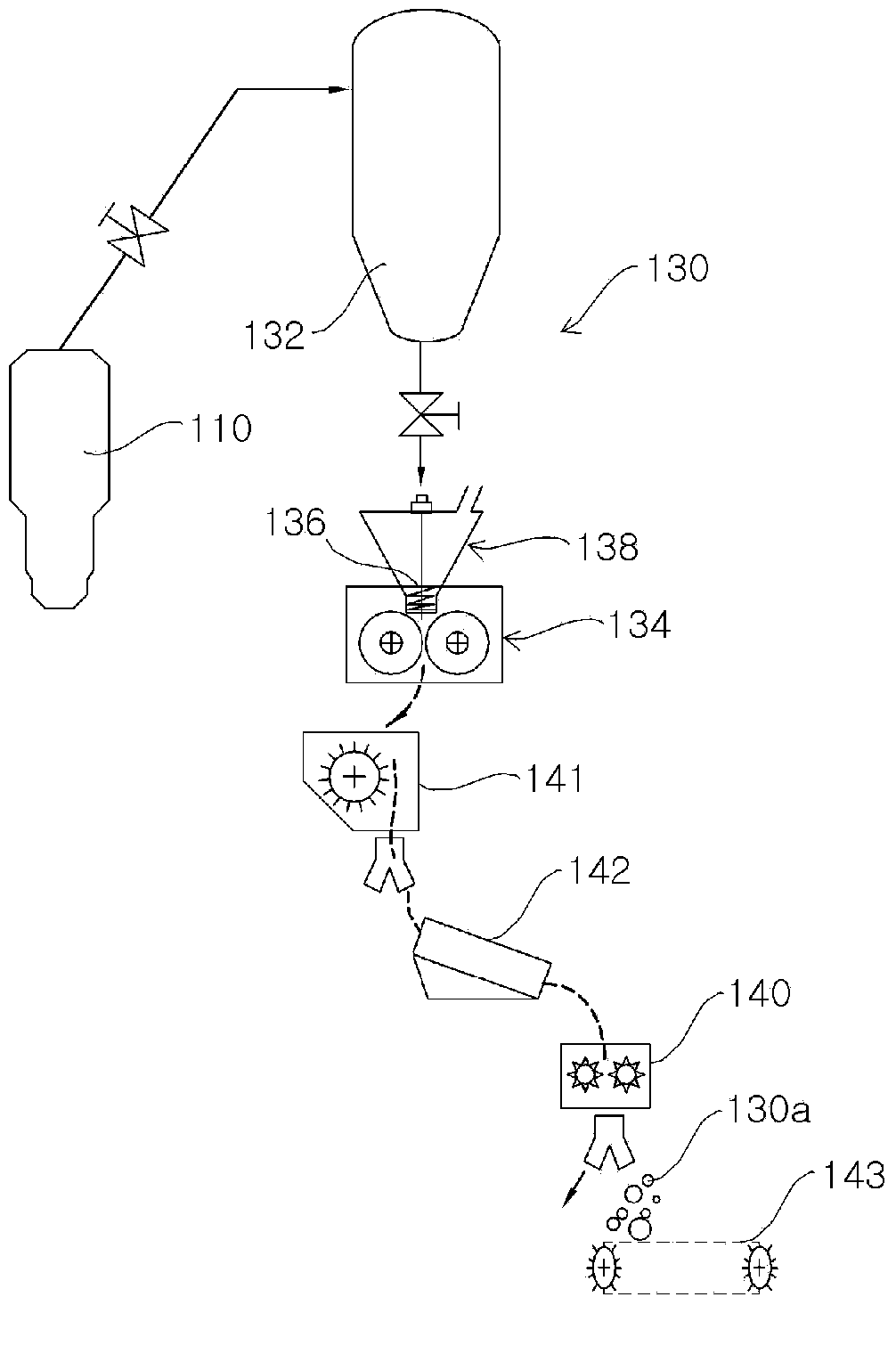

[0044] first, Figure 1 to Figure 3 Schematically shows the molten iron manufacturing equipment 100 using steam coal and fine iron ore, the molten iron manufacturing equipment 100 includes a block manufacturing unit 130, the block manufacturing unit 130 has a driving part sealing device ( image 3 Part 'A') of the screw feeder hopper 138.

[0045] For example, iffigure 1 As shown, the molten iron manufacturing facility 100 that directly uses steam coal and fine iron ore to manufacture molten iron includes a plurality of reduction furnaces 110 , a lump manufacturing unit 130 , a lump storage tank 150 , and a melting furnace 170 . A molten iron manufacturing facility 100 having such a structure is known.

[0046] However, as explained above, in order to ensure the gas permeability in the melting furnace 170, the reduced iron passed through the reduction furnace is manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com