A circulating fluidized bed flue gas desulfurization, denitrification and mercury integrated device and method

A technology of desulfurization, denitrification and mercury removal, circulating fluidized bed, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of easy corrosion of devices, heavy maintenance workload, easy blockage and corrosion of equipment, and achieve The effect of strengthening the catalytic oxidation ability, adapting to boiler load changes, and saving the purchase of absorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

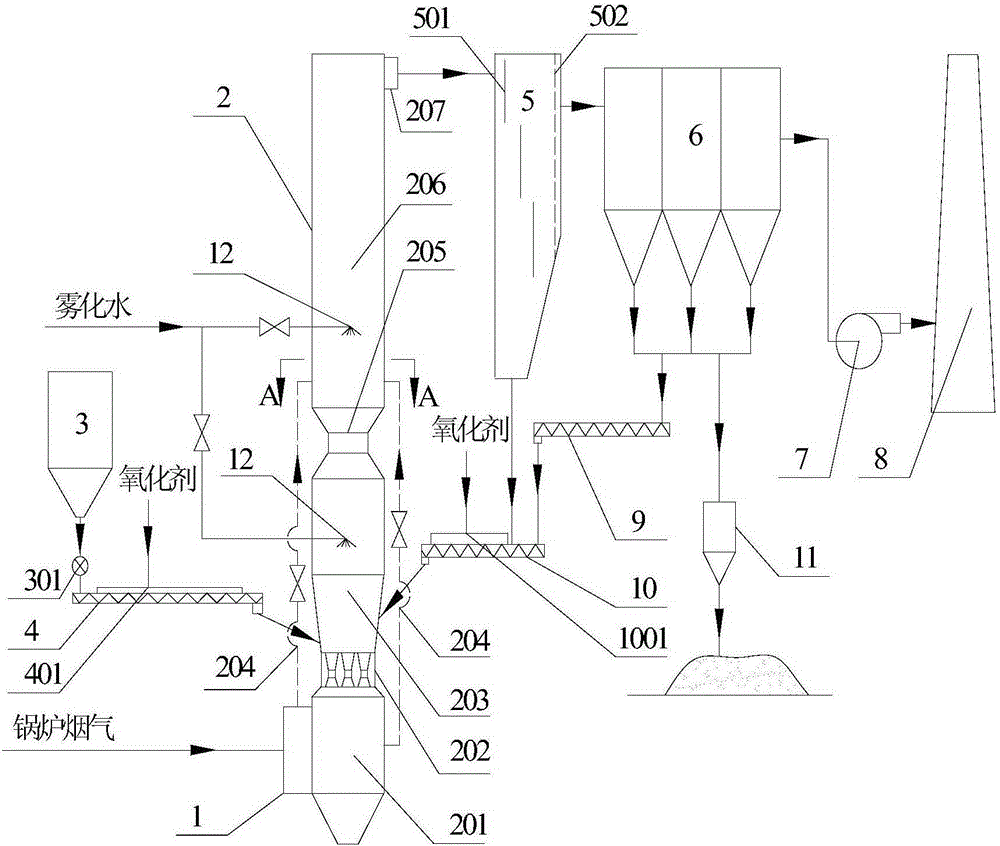

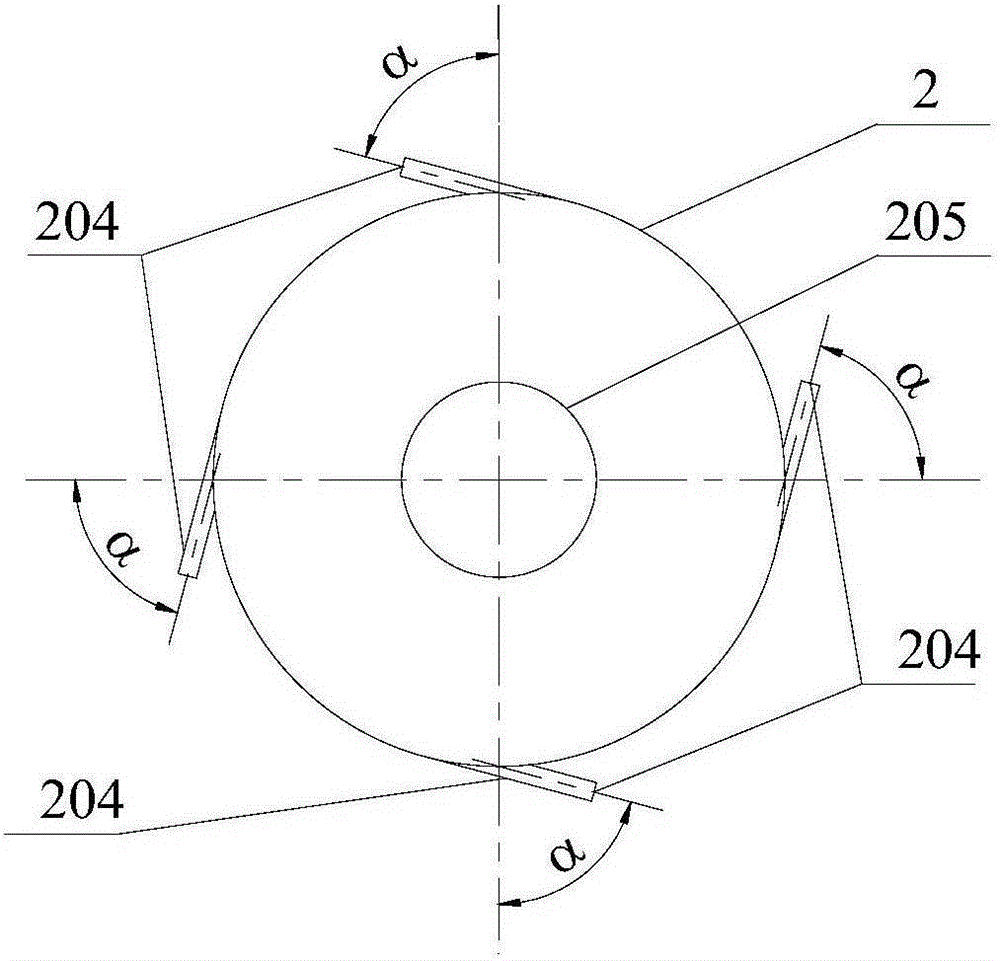

[0025] Such as figure 1As shown, a circulating fluidized bed flue gas desulfurization, denitrification and mercury removal integrated device involved in the present invention includes an inlet flue 1, a circulating fluidized bed absorption tower 2, an absorbent storage bin 3, a feeder 301, an absorption Agent activator 4, atomizing spray gun 12, pre-dust collector 5, bag filter 6, return device 9, return activator 10, ash bin pump 11, induced draft fan 7 and chimney 8, wherein the circulating fluidized bed reaction Tower 2 is provided with a smoke chamber 201, a Venturi tube 202, a primary reaction zone 203, a constriction 205, a secondary reaction zone 206 and a reaction tower outlet 207, a primary reaction zone 203 and a secondary reaction zone 206 from bottom to top. Atomizing spray guns 12 are respectively arranged inside, and 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com