Crimping fixture of reflective paper of LED (Light Emitting Diode) fluorescent lamp

A technology of LED fluorescent lamps and reflective paper, which is applied in packaging and other directions, can solve the problems of uneven reflective paper, affecting the reflective efficiency of reflective paper, and the uniformity of light output, etc., to achieve smooth reflective paper, uniform reflective effect, and good adhesion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

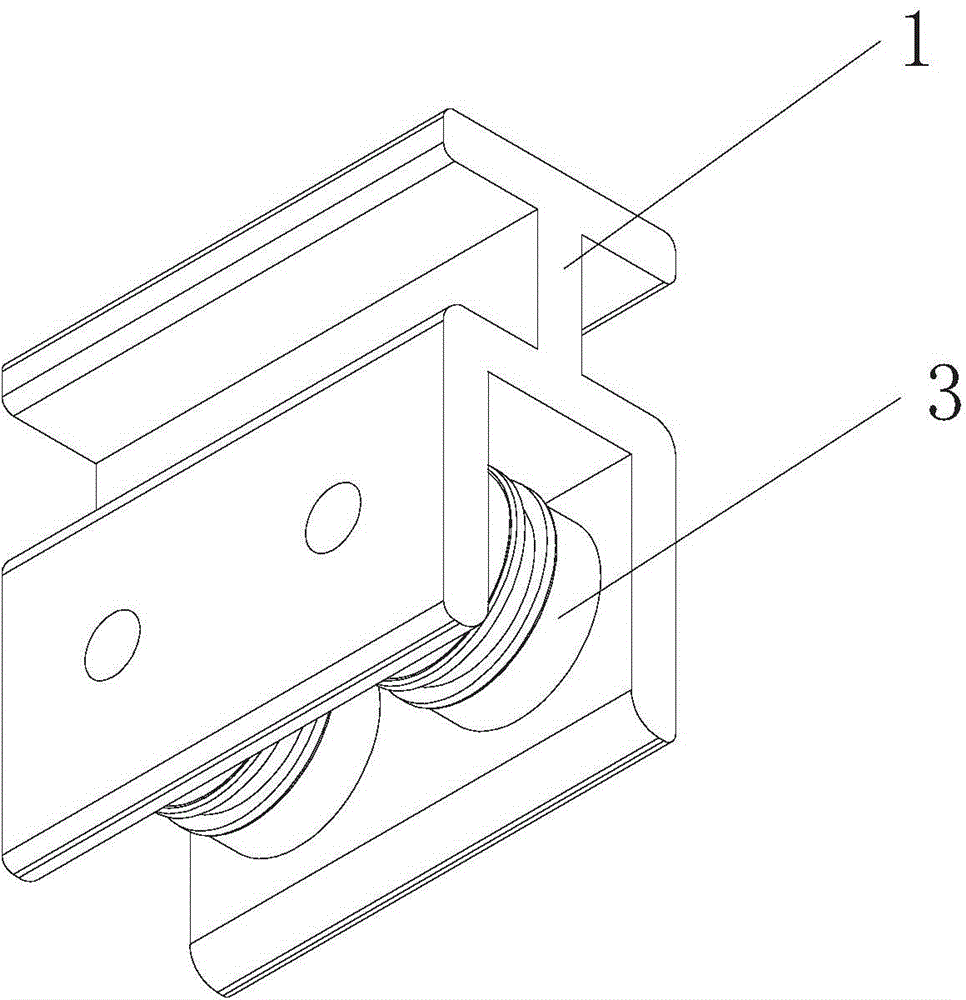

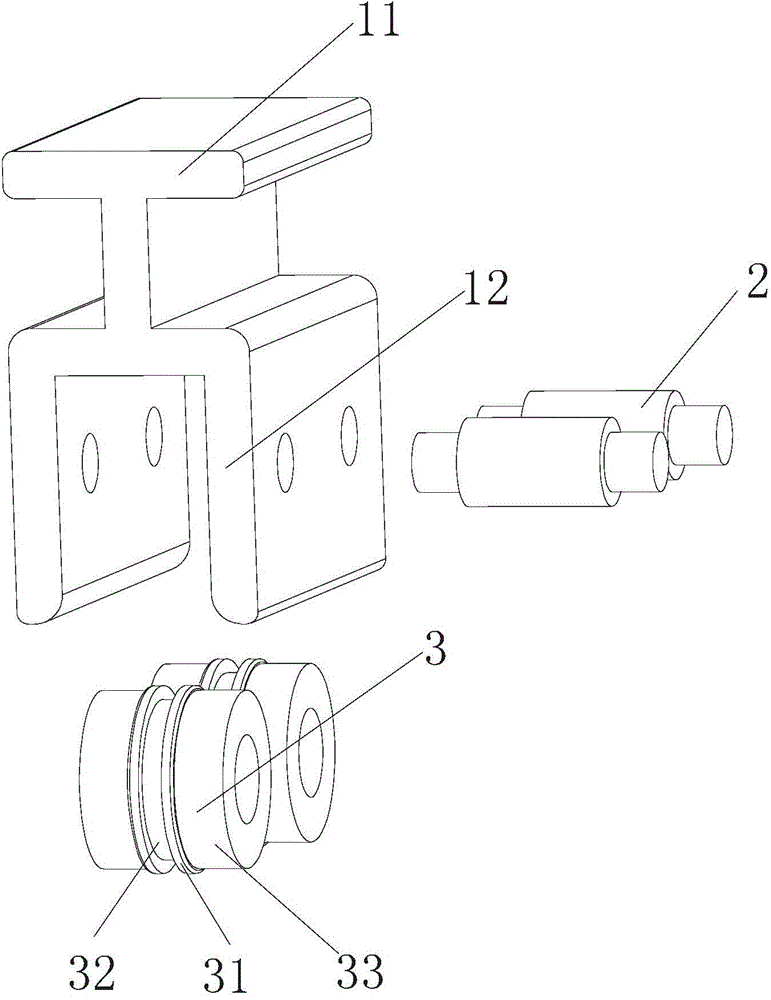

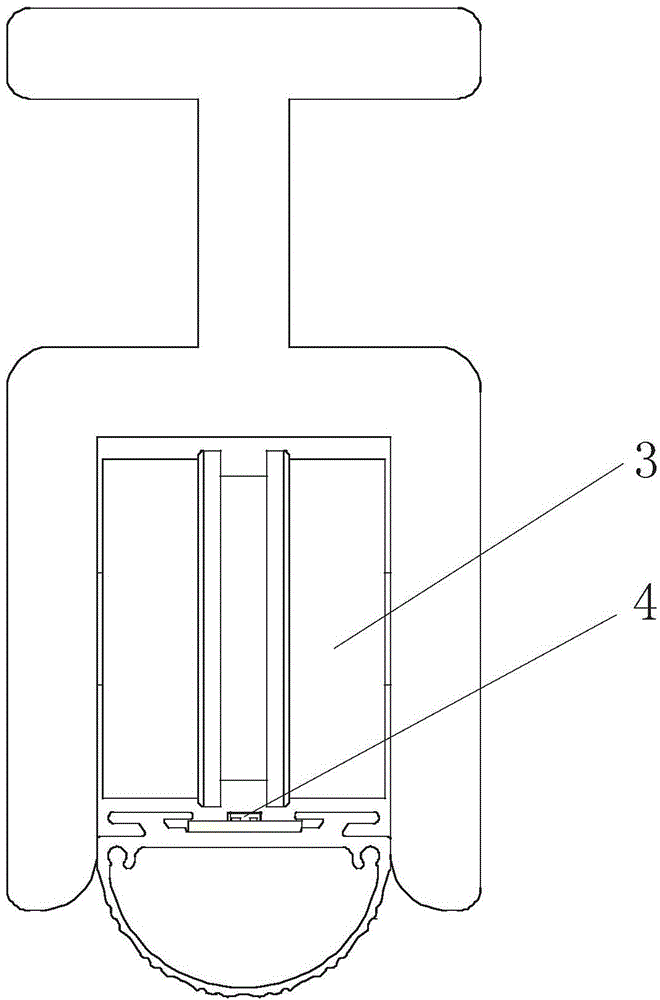

[0017] Such as figure 1 , figure 2 As shown, a LED fluorescent lamp reflective paper pressing fixture has a fixed frame 1, a bearing 2, and a rolling wheel 3. The fixed frame 1 includes an armrest bracket 11 and a mounting bracket 12. The rolling wheel 3 is installed on the bearing 2. The bearing 2 is installed on the mounting bracket 12 of the fixed frame 1, and the wheel surface of the rolling wheel 3 is provided with an annular protrusion 31 for rolling reflective paper.

[0018] The armrest bracket 11 is located at the top of the mounting bracket 12 . Handrail support 11 is T font, and installation support 12 is a 冂 shape, and handrail support 11 is positioned at the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com