Hydraulic combining system for pusher and side shifter of forklift

A technology of hydraulic system and ejector, applied in the direction of lifting device, etc., can solve problems such as affecting the normal operation of the driver, occupying the upper space of the oil port, and messy pipeline connection, etc., to improve the appearance quality, reduce the loss of load distance, pipeline Connection for reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

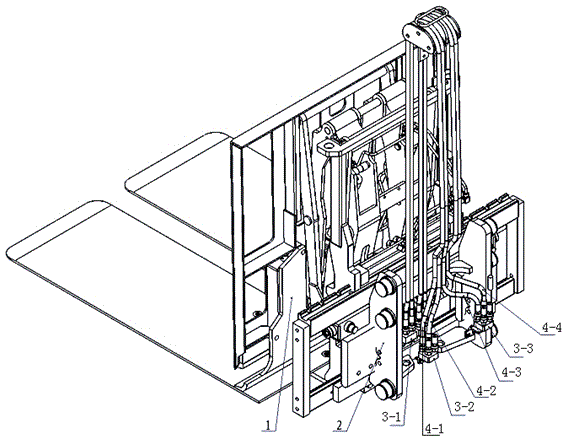

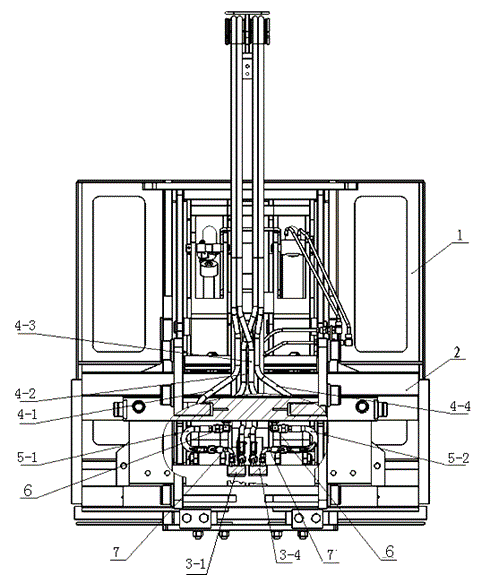

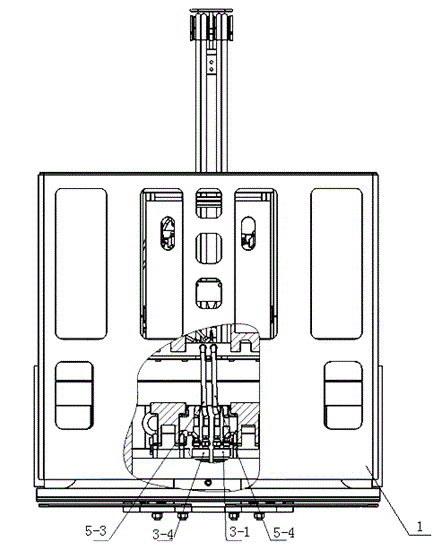

[0034] Such as Figure 1-3 As shown, the combined hydraulic system for the forklift ejector and side shifter includes the ejector 1, the multi-way valve and the first high-pressure rubber hose 4-1, the second high-pressure rubber hose 4-2, and the third high-pressure rubber hose 4-3. Two high-pressure hydraulic oil circuits formed with the fourth high-pressure rubber hose 4-4.

[0035]

[0036] Such as Figure 5 As shown, an upper hook 1-1 is respectively set at both ends of the upper beam of the front end of the ejector (1), and a lower hook 1-2 is respectively set at both ends of the lower beam.

[0037]

[0038] Such as Figure 6 , 7 As shown, the integral side shifter 2 includes a frame 2-3 and a side shift cylinder 2-4, and the upper and lower beams of the frame 2-3 are respectively provided with an upper notch 2-1 and a lower notch 2-2. The front end of the integral side shifter 2 is provided with a second four-way joint 3-2 and a third four-way joint 3-3, and a fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap