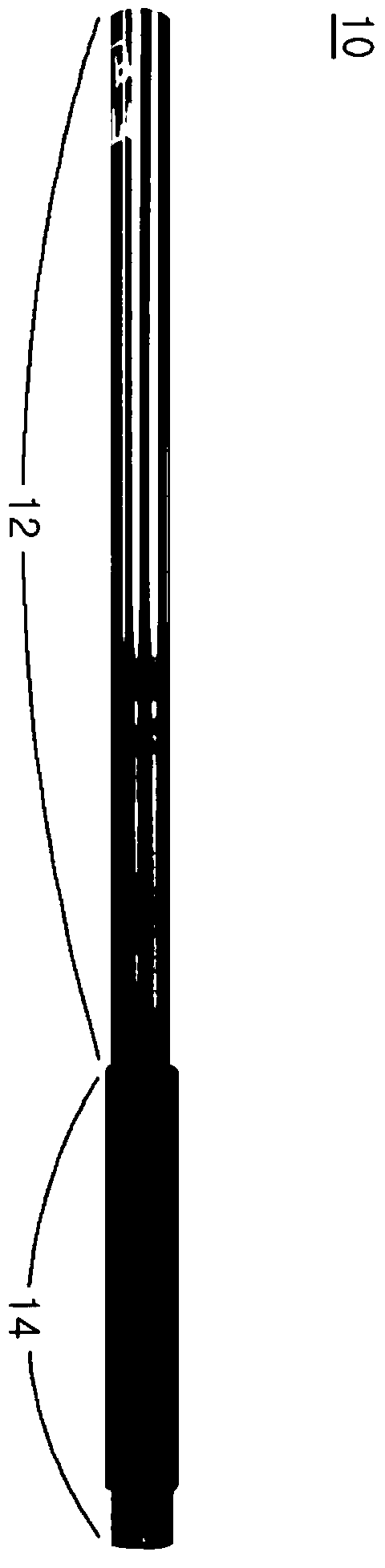

Induction heating heat-treating method of car VGR (variable rack ratio) rack bar

A heat treatment method and induction heating technology, applied in heat treatment furnaces, heat treatment equipment, process efficiency improvement, etc., can solve secondary defects and other problems, achieve excellent product quality, and eliminate appearance indentation or scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

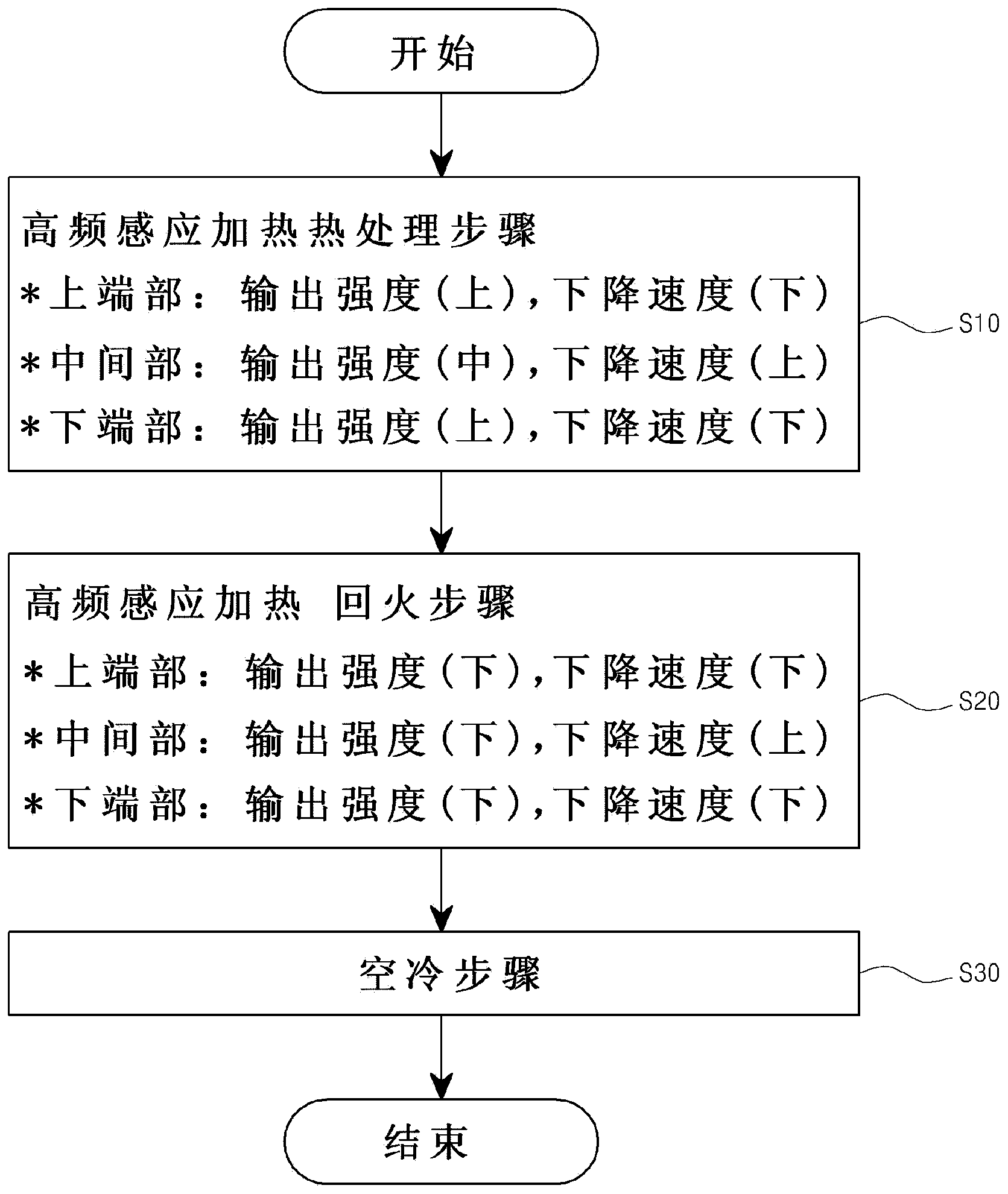

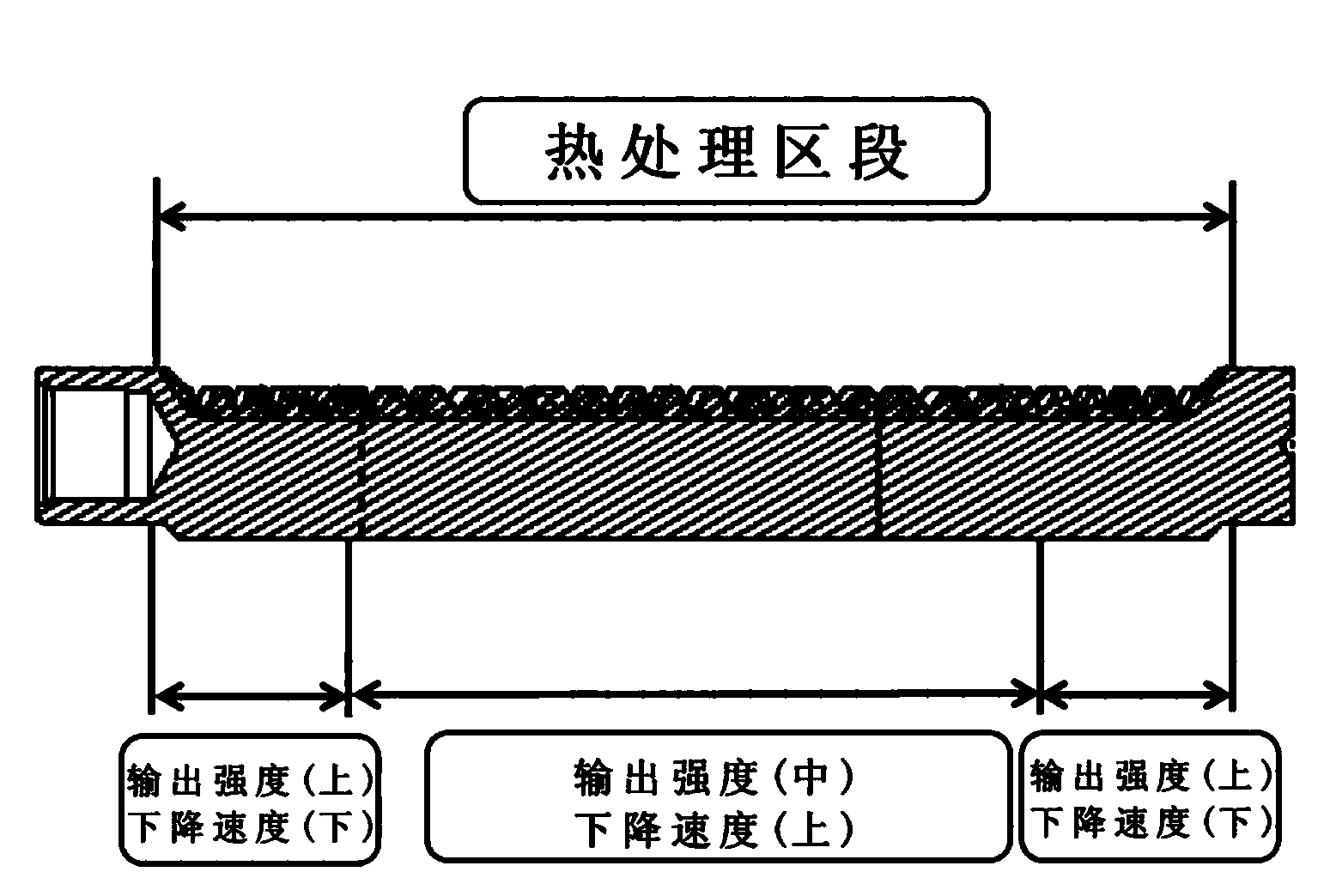

[0055] Purchasing 150kW×9kHz high-frequency induction heating equipment, according to Figure 4 After the VGR gear rod is fixed in the way shown, the high-frequency induction heating equipment is used for high-frequency heat treatment. First, the high-frequency heat treatment step sets the output to 6.3 and the descending speed to 7.0 at the upper end, the output to 6.0 and the descending speed to 9.0 at the middle, and the output to 6.3 at the lower end And set the descending speed to 7.0, and then carry out high-frequency induction heating heat treatment. At this time, the VGR gear bar is lowered in a non-rotating state, and is simultaneously water-cooled by a water-cooling supply device while performing high-frequency induction heating heat treatment.

[0056] After the high-frequency induction heating heat treatment is completed, in the same high-frequency induction heating device, the VGR gear bar is lowered in a non-rotating state and high-frequency tempering is perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com