Extrusion machining method for automobile anti-collision beam

A technology of extrusion processing and anti-collision beams, which is applied in the direction of manufacturing tools, furnaces, furnace types, etc., can solve the production problems of anti-collision beams and other automotive components, and it is difficult to meet high quality, high strength, high elastic modulus and other problems , to achieve the effect of eliminating impurities and appearance defects, reducing product defects and improving the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

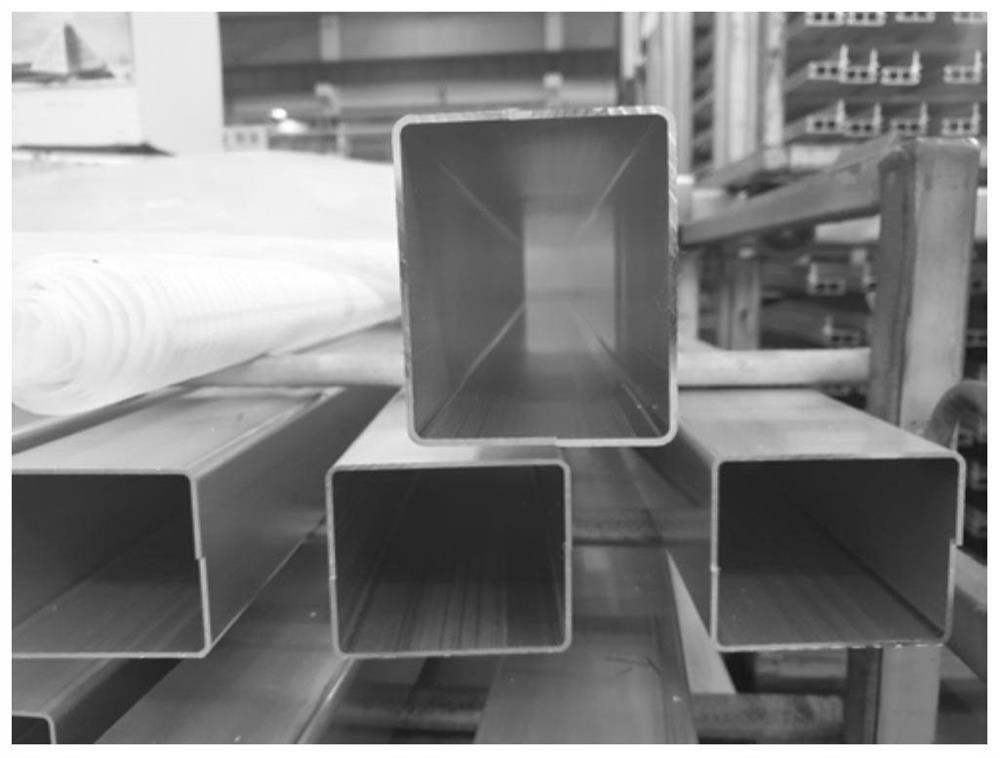

[0039] This embodiment provides a method for extrusion processing of an automobile anti-collision beam, comprising the following steps:

[0040] Pretreatment: Peel the aluminum rods to remove skin impurities;

[0041] Preheating: first put the aluminum rod into the gas preheating furnace (Zhaoqing Keda Machinery Manufacturing Co., Ltd.) for primary heating, set the heating temperature to 320 ° C, and the heating time to 2 hours, then put the aluminum rod into the intermediate frequency heating furnace (OTTO JUNKER company) for secondary heating, using the stepped heating method, setting the heating temperature of the head of the aluminum rod to 530-535°C, the heating temperature of the tail of the aluminum rod to 480-485°C, and the time of secondary heating to 6min;

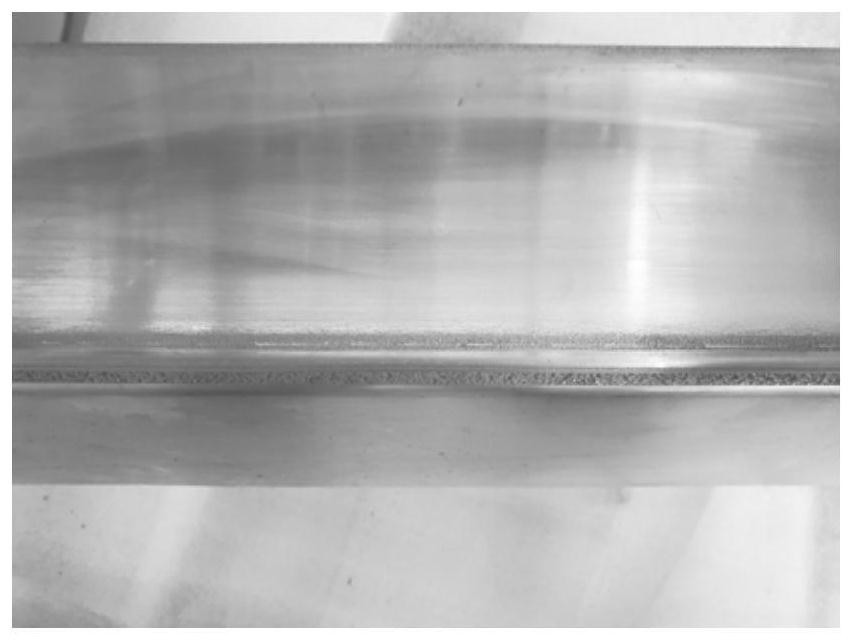

[0042] Extrusion: After preheating, put the aluminum rod into the extruder for extrusion, set the advancing speed of the extrusion head to 2.8mm / s, the temperature of the ingot barrel to 420°C, and the temperatur...

Embodiment 2

[0046] This embodiment provides a method for extrusion processing of an automobile anti-collision beam, comprising the following steps:

[0047] Pretreatment: Peel the aluminum rods to remove skin impurities;

[0048] Preheating: First put the aluminum rod into the gas preheating furnace for primary heating, set the heating temperature to 350°C, and the heating time for 2.5h, then put the aluminum rod into the intermediate frequency heating furnace for secondary heating, using step heating method, set the heating temperature of the head of the aluminum rod to 525-530°C, the heating temperature of the tail of the aluminum rod to 475-480°C, and the secondary heating time to 6 minutes;

[0049] Extrusion: After preheating, put the aluminum rod into the extruder for extrusion, set the advancing speed of the extrusion head to 2.8mm / s, the temperature of the ingot barrel to 395°C, and the temperature of the discharge port to 550°C , during the extrusion process, the mold is cooled wi...

Embodiment 3

[0053] This embodiment provides a method for extrusion processing of an automobile anti-collision beam, comprising the following steps:

[0054] Pretreatment: Peel the aluminum rods to remove skin impurities;

[0055] Preheating: first put the aluminum rod into the gas preheating furnace for primary heating, set the heating temperature to 315°C, and heat for 3 hours, then put the aluminum rod into the intermediate frequency heating furnace for secondary heating, adopting the method of step heating , set the heating temperature of the head of the aluminum rod to 525-530°C, the heating temperature of the tail of the aluminum rod to 475-480°C, and the secondary heating time to 6 minutes;

[0056] Extrusion: After preheating, put the aluminum rod into the extrusion machine for extrusion, set the advancing speed of the extrusion head to 2.5mm / s, the temperature of the ingot barrel to 395°C, and the temperature of the discharge port to 550°C , during the extrusion process, the mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com