Preparation method of carbon-tin composite conducting film

A conductive film and tin chloride technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of preparing a single carbon film diamond film, which has not been reported in the literature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

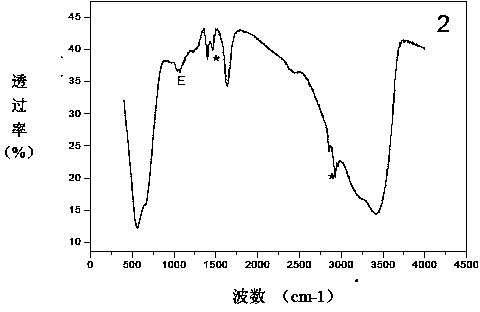

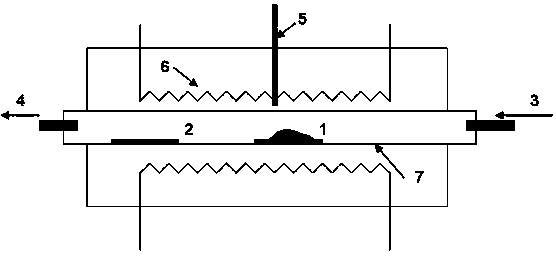

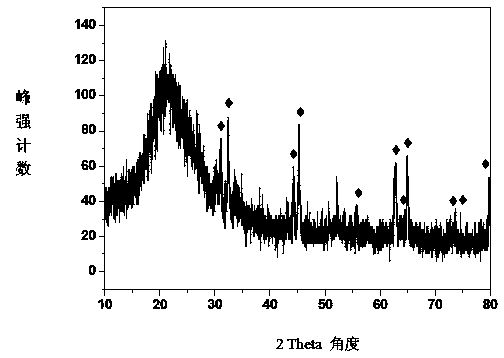

[0026] Weigh 10g tin tetrachloride pentahydrate (SnCl 4 5H 2 O, CAS: 10026-06-9) was dissolved in 1 liter of absolute ethanol. Ammonia water is slowly dropped into the alcohol solution to increase the pH of the alcohol / water mixture, and it can be observed that flocculent colloids are formed in the solution. Stir the solution continuously to complete the hydrolysis of tetravalent tin. After three hours, the final pH is controlled at about 8. Stand the solution, it can be seen that the solution is layered, the upper layer is a clear alcohol aqueous solution, and the lower layer is a white Sn hydrolyzate (colloidal). Chloride ion exchange resin is added to the layered mixture to carry out exchange and removal of chloride ions. Separation of saturated chloride ion exchange resin particles, adding fresh chloride ion exchange resin, repeated several times until the concentration of chloride ion in the alcohol aqueous solution is lower than 5mg / L. Distill the alcoholic aqueous s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap