Coating equipment for flat sheet membrane

A film coating and equipment technology, applied in the field of flat film coating equipment, can solve the problems of equipment production efficiency reduction, easy damage, slow gel speed, etc., and achieve the improvement of film quality, production efficiency and uniform thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

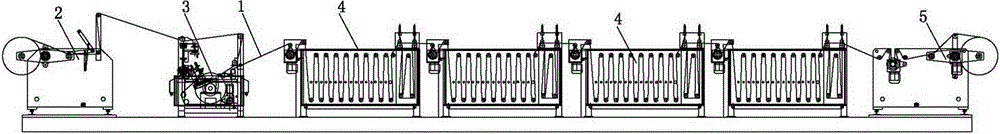

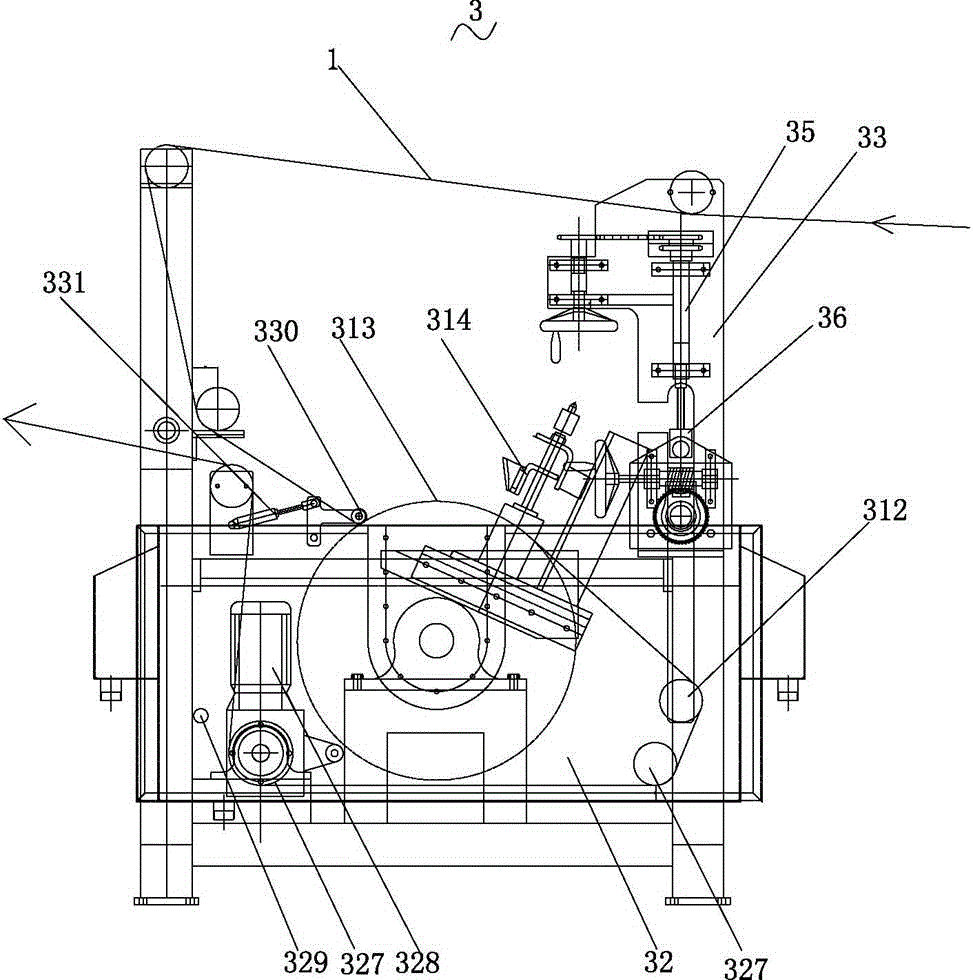

[0032] Please refer to the attached figure 1 To attach Figure 8 Shown, the present invention is a kind of flat film coating equipment, and it is used for coating film on base cloth 1, and it is composed of several parts such as feeding device 2, gluing gel device 3, water washing device 4 and winding device 5 composition.

[0033] Wherein, the feeding device 2, the gluing and gelling device 3, the washing device 4 and the winding device 5 are sequentially connected to realize continuous production. There are four washing devices 4, and the four washing devices 4 are connected in series.

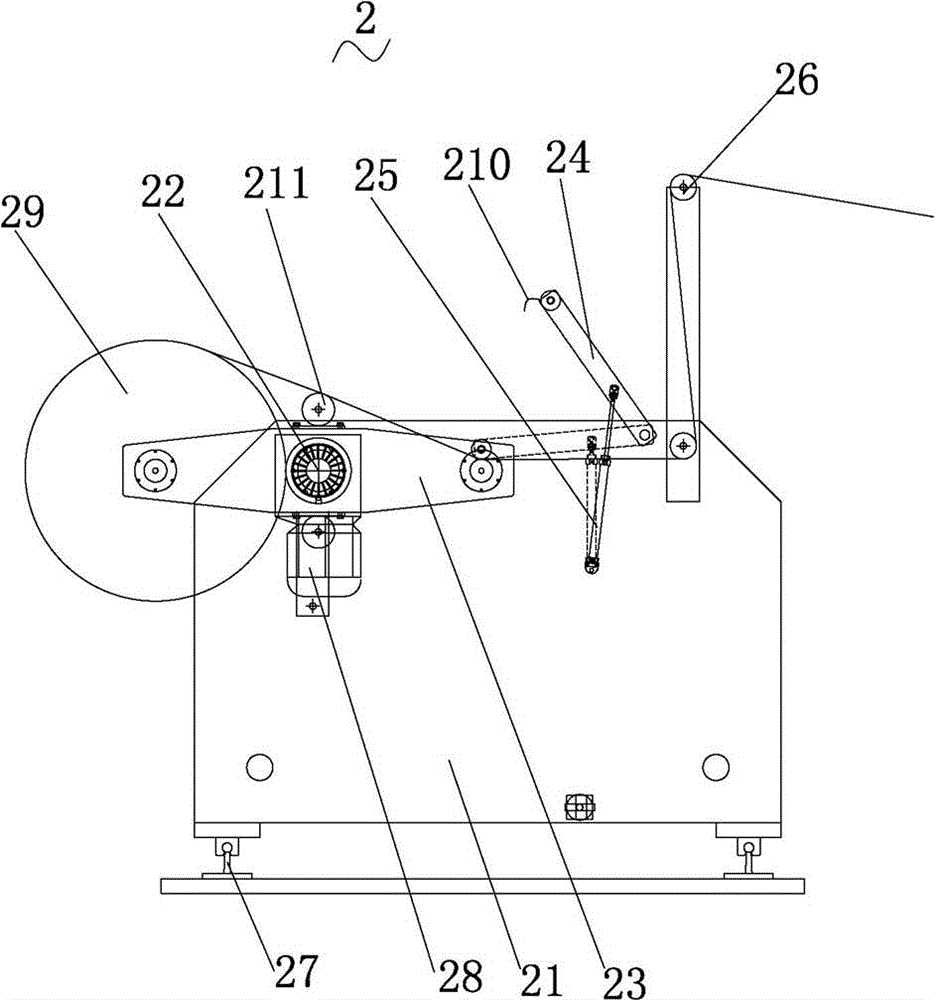

[0034] Described feeding device 2 is made up of several parts such as support 21, turning shaft 22, turning frame 23, cutting knife rest 24, cutting off cylinder 25 and delivery roller group 26.

[0035] Wherein, a pair of rails 27 are arranged at the bottom of the bracket 21 , the bracket 21 is supported on the rails 27 and can slide along the rails 27 so as to adjust the position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com