Device and process for preparing and conveying solutions of chemicals

A technology of chemical and liquid preparation, which is applied in the field of printing and dyeing, can solve the problems of inconsistency in pre-treatment fabric related indicators, damage to the economic benefits of enterprises, and increase in production costs, and achieve the goals of easy production expansion, beneficial to environmental protection, and reduced labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

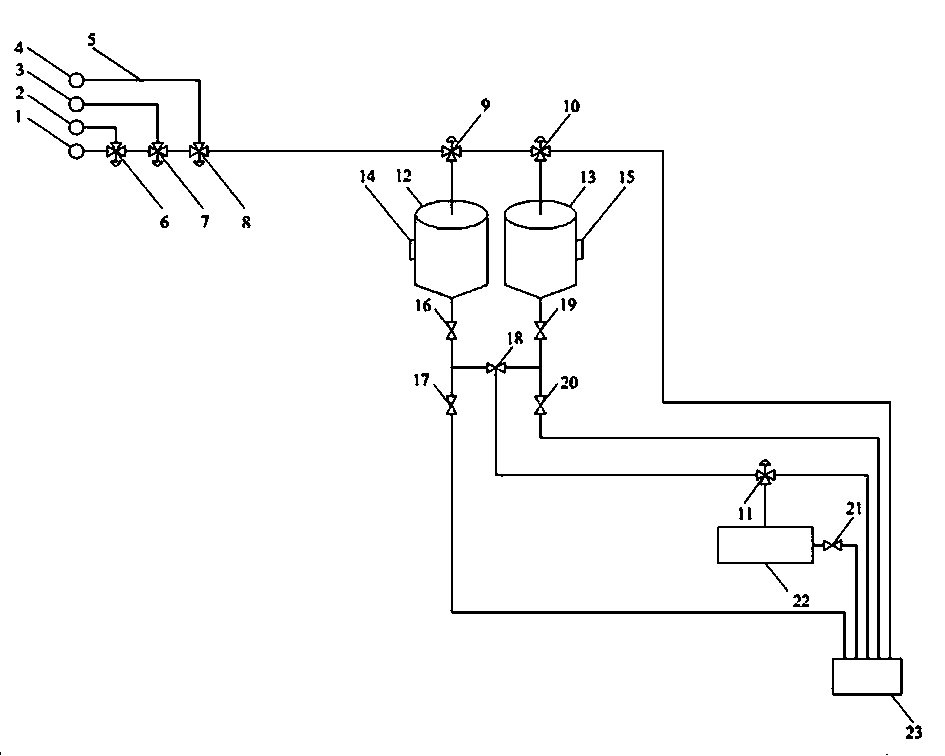

[0030] Below in conjunction with accompanying drawing, the present invention will be further described.

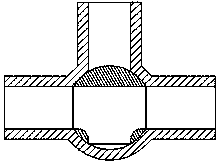

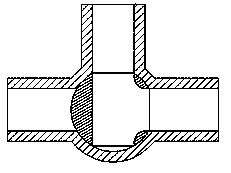

[0031] The overall structure of the long-distance conveying device is as follows: figure 1 As shown, the initial position of the three-way valve is as figure 2 As shown in a), the initial position of the angle seat valve is as follows image 3 a) as shown. After the system starts to work, the first three-way valve 6 and the fourth three-way valve 9 switch directions to communicate with the water tank 2 and the first liquid distribution cylinder 12 . The water in the water tank 2 enters the first liquid distribution cylinder 12 through the delivery pipe 5 . After conveying for a certain period of time, the first three-way valve 6 is switched to connect the chemical barrel 1 and the first liquid distribution cylinder 12 , and the chemicals in the chemical barrel 1 enter the first liquid distribution cylinder 12 through the delivery pipeline 5 . After running for a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com