Prestressed supporting structure for long rectangular foundation pit

A support structure and prestressing technology, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems of high cost of foundation pit support, low reuse rate of steel pipes, and large amount of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

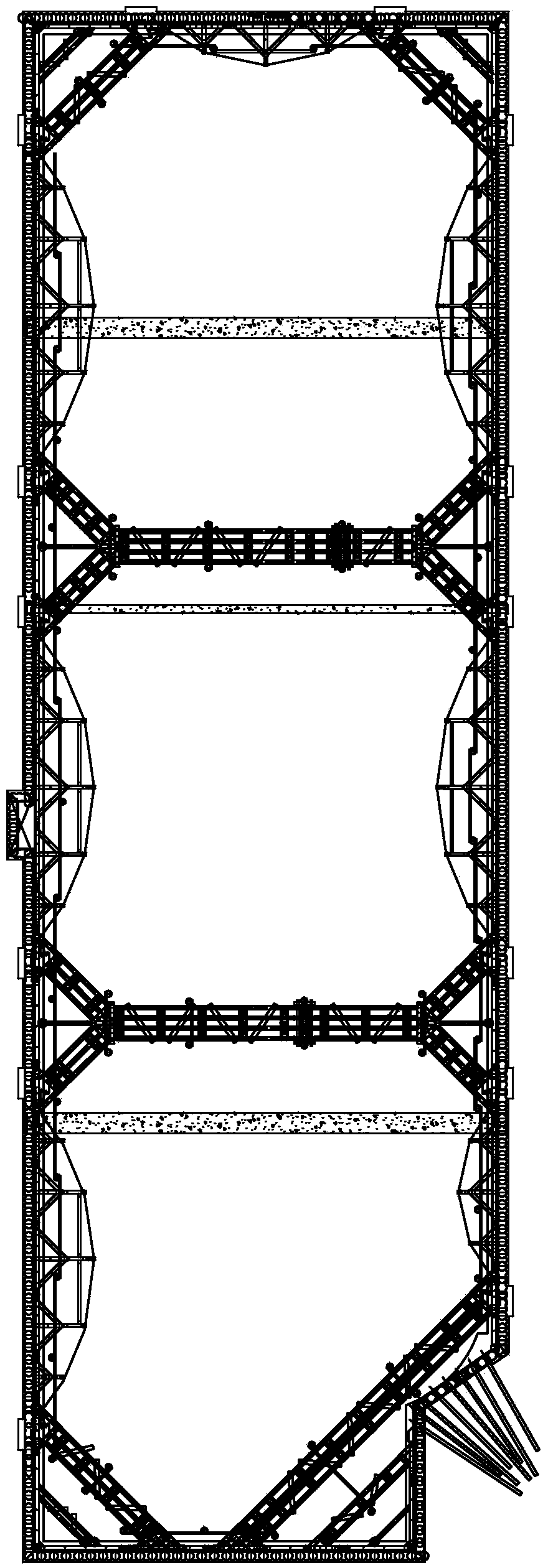

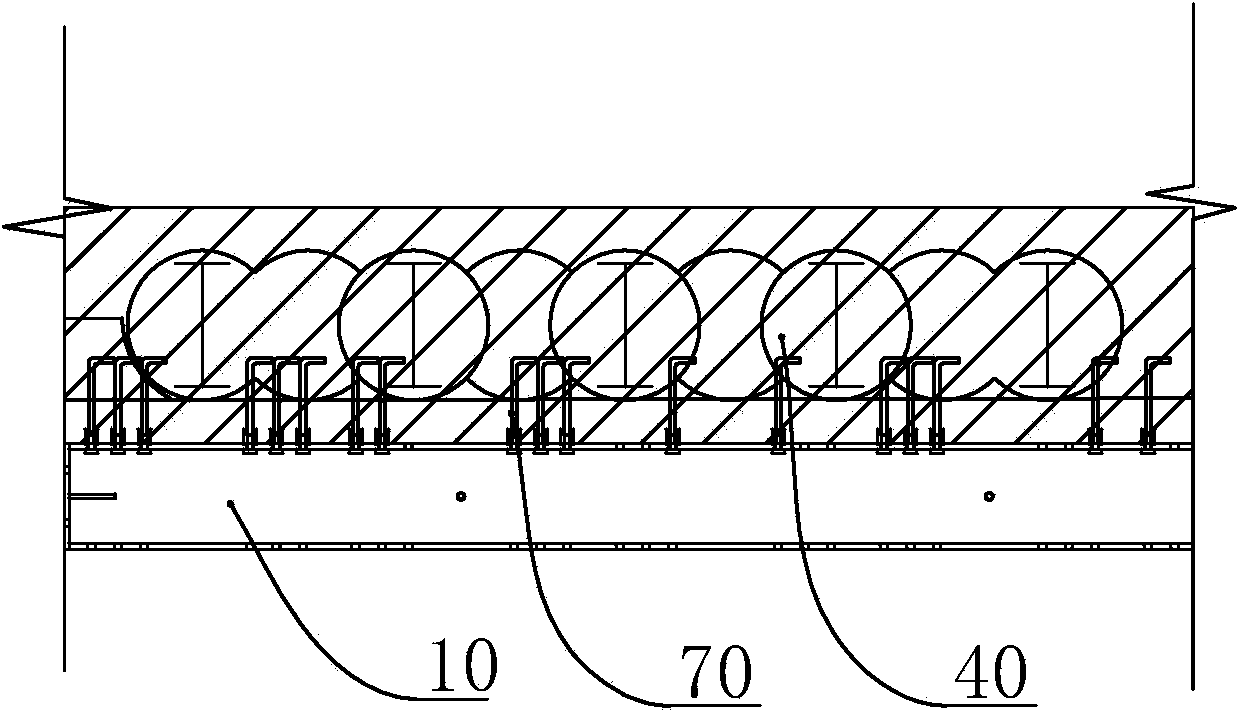

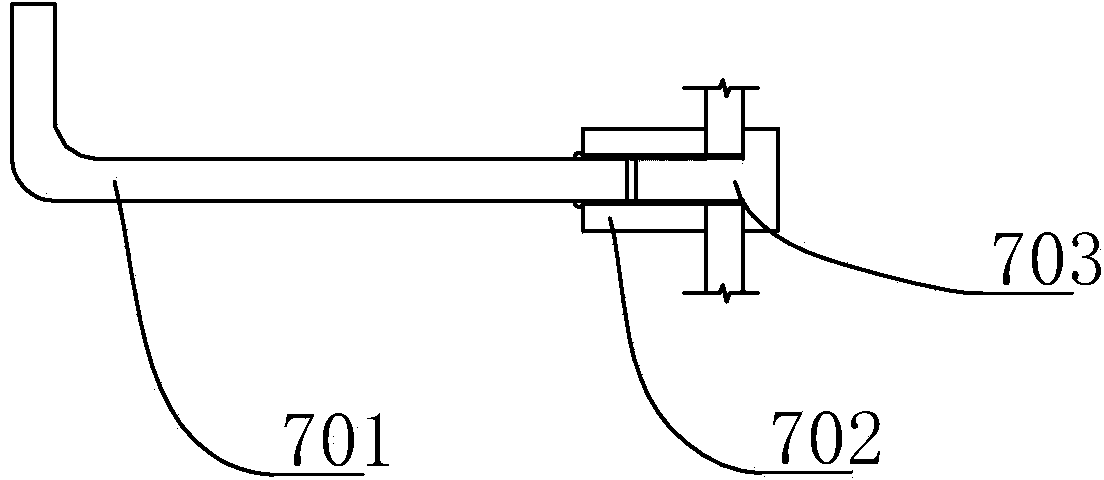

[0075] according to Figure 1 to Figure 28 As shown, a prestressed support structure for a long rectangular foundation pit described in this embodiment includes cement mixing piles 40 driven downward along the outer periphery of the foundation pit, and the upper part of the cement mixing piles is poured with a reinforced concrete structure. For the top beam, the inner circumference of the top beam is connected with purlin-shaped steel 10, and the purlin-shaped steel is fixedly connected with the top beam through a steel bar connector 70.

[0076] The purlin-shaped steel is H-shaped steel, and the flanges on both sides are equidistantly provided with connecting hole groups, each connecting hole group is composed of two connecting hole units, and each connecting hole unit has six connecting holes, six The connecting holes are distributed i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap