High-performance bionic blast wall

A high-performance, explosion-proof wall technology, applied in the direction of walls, building components, building types, etc., can solve the problems of debris splashing, personnel injury, wall rupture, etc., and achieve good promotion prospects, material saving, and thickness reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

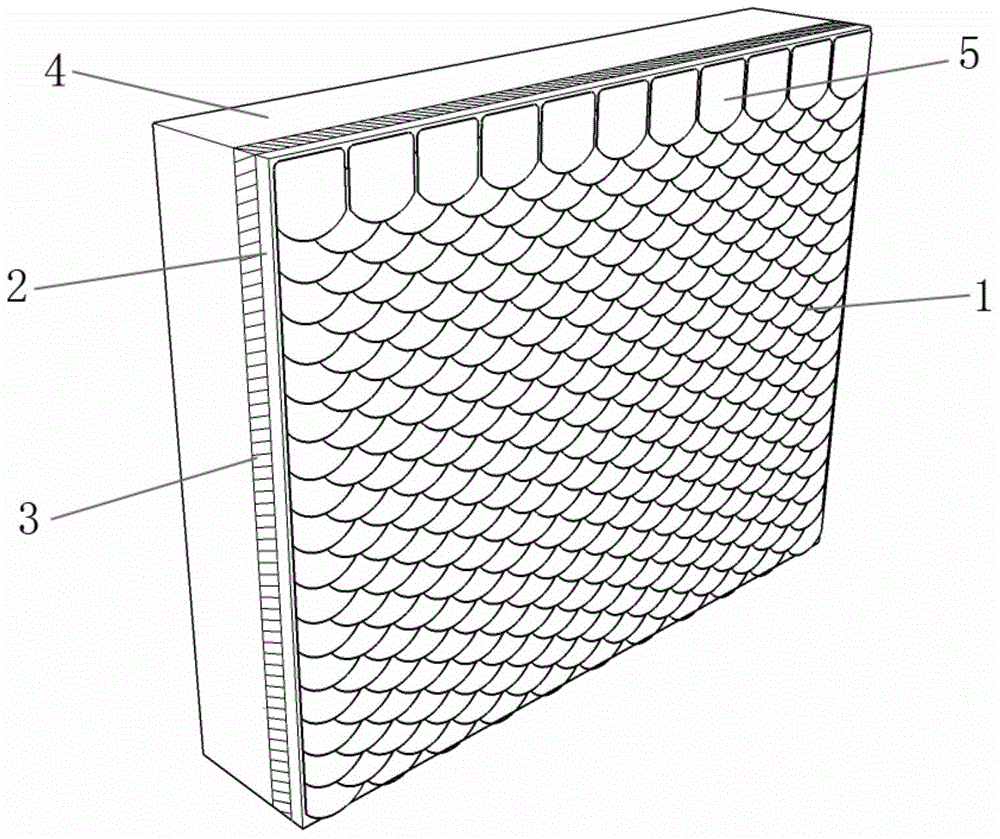

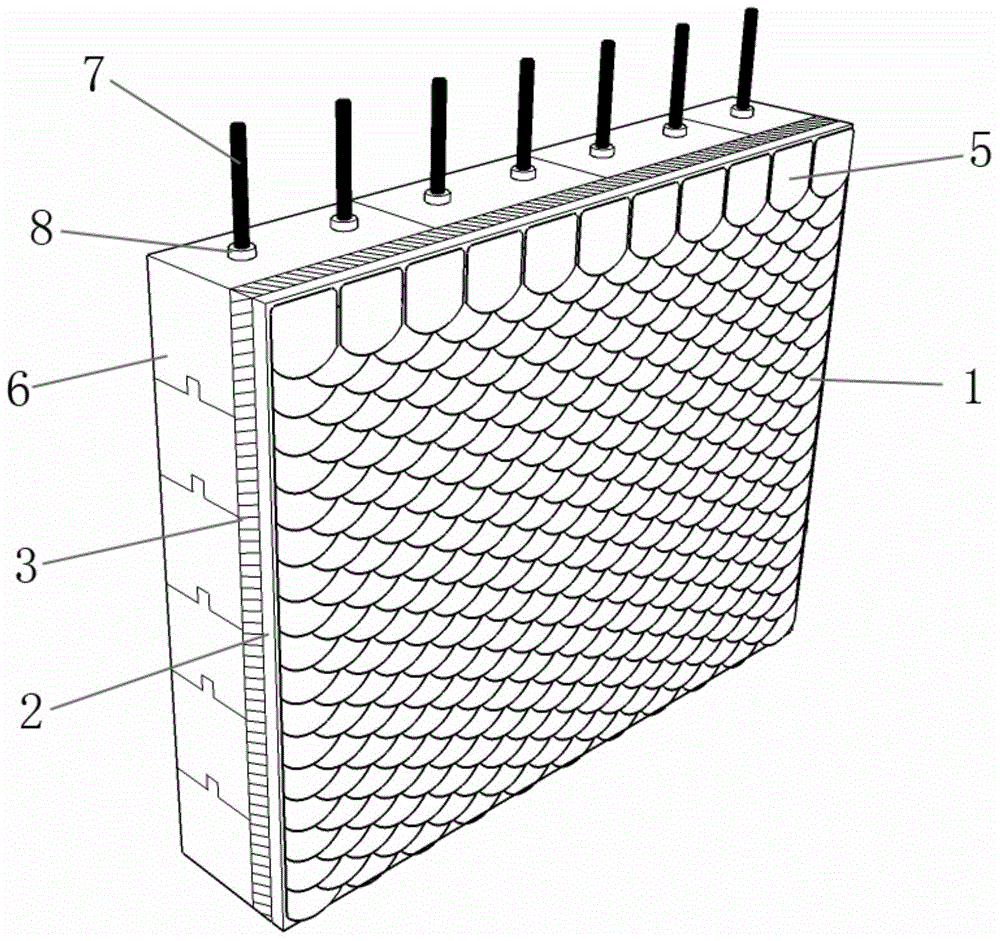

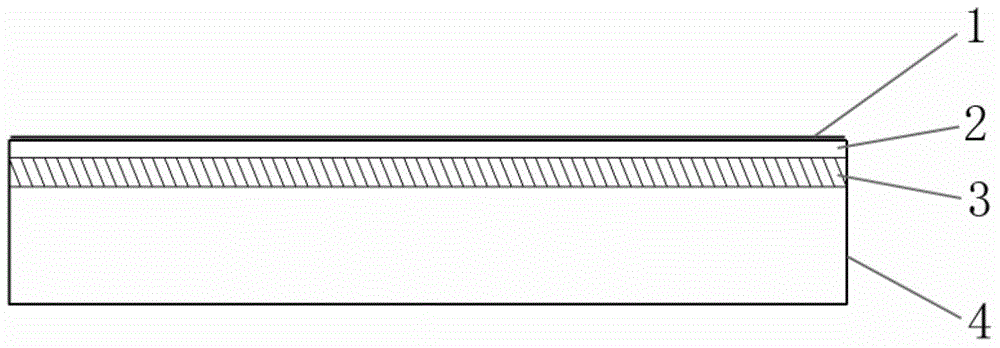

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 It is a three-dimensional structural schematic diagram in which the high-performance wall is an ultra-high-performance reinforced concrete wall in the present invention. Wherein, the explosion-proof wall provided by the present invention consists of two parts, an FRP protective layer and a high-performance wall body. Such as figure 2 As shown, the FRP protective layer is composed of fish scale FRP layer, rubber layer and polyurethane foam layer. The scale-like FRP layer has excellent characteristics of high temperature resistance and impact resistance, and is an ideal protective material, and it draws lessons from the imbricate structure of fish scales, which can better resist impact loads. The scale-like FRP layer is made of fiber cloth into fish scales with impregnated glue, and pasted on a layer of fiber cloth according to the arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com