High porosity shale hollow block powder grading and sieving device

A technology of hollow blocks and porosity, applied in the direction of solid separation, separating solids from solids with air flow, chemical instruments and methods, etc., can solve the problem that the products under the sieve do not meet the requirements, cannot produce hollow bricks, and the production impact of hollow bricks and other problems, to achieve the effect of not easy to block the screen hole, high material screening efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

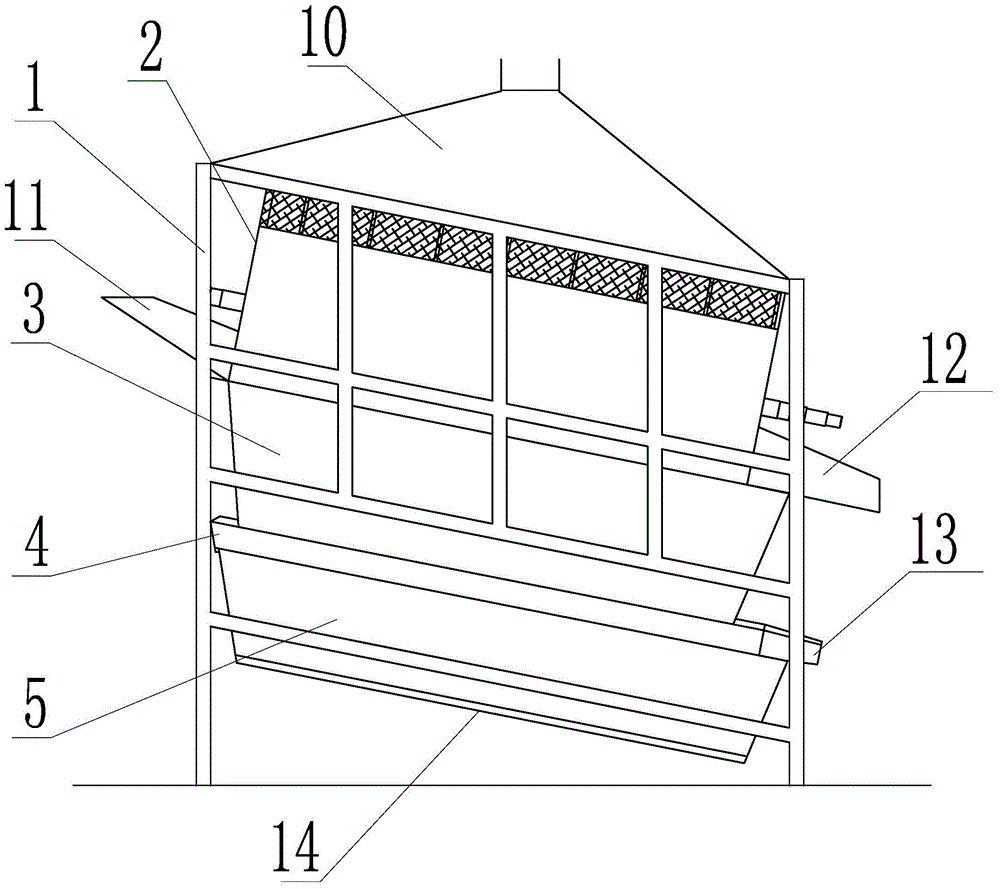

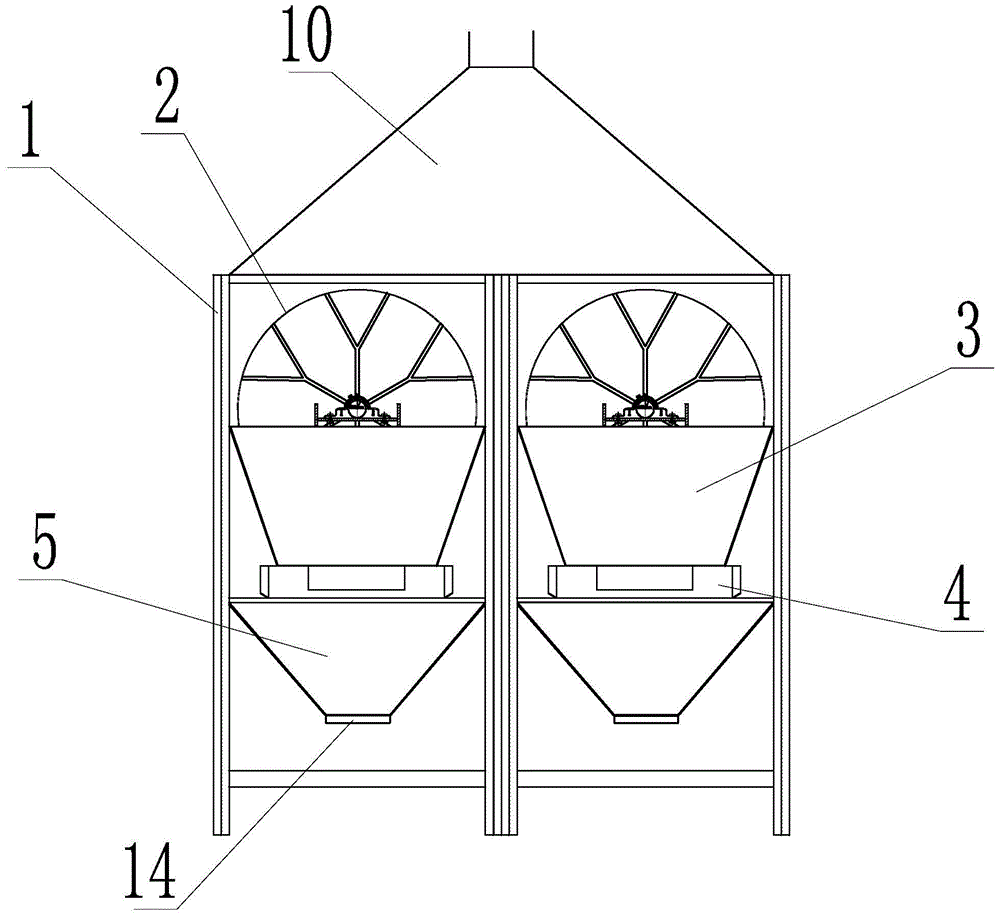

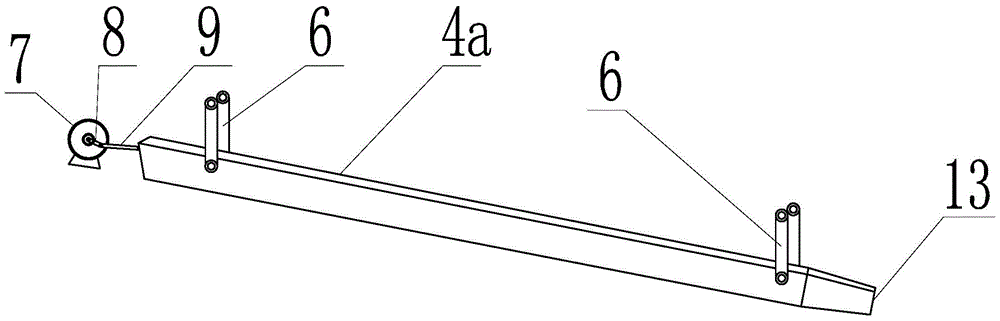

[0021] Such as figure 1 and figure 2 Shown: a high-porosity shale hollow block powder grading and sieving device, which consists of two sifting devices arranged side by side. Of course, the sieving devices can also be 1, 3, 4, 5 or 6, etc., as long as Can meet the demand of corresponding powder sifting quantity, this powder sieving device is made up of frame 1, drum sieve 2, coarse material hopper 3, vibrating screen 4 and fine material hopper 5, described drum sieve 2, coarse material hopper 3 , the vibrating screen 4 and the fine material hopper 5 are sequentially fixed on the frame 1 from top to bottom; The midlines along the left-right direction of the bottom surfaces of the coarse material hopper 3, the vibrating screen 4 and the fine material hopper 5 are all parallel to the central axis of the trommel 2; the left end of the trommel 2 is a feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com