Shale decoration brick and shale insulating brisk combined building clean water composite wall and combined building method

A technology for decorative bricks and thermal insulation bricks, which is applied to walls, building components, buildings, etc., can solve the problems of complex construction technology, no shale decorative bricks and clear water composite walls, etc., achieve good livability, eliminate fire hazards, The effect of strong controllability of quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

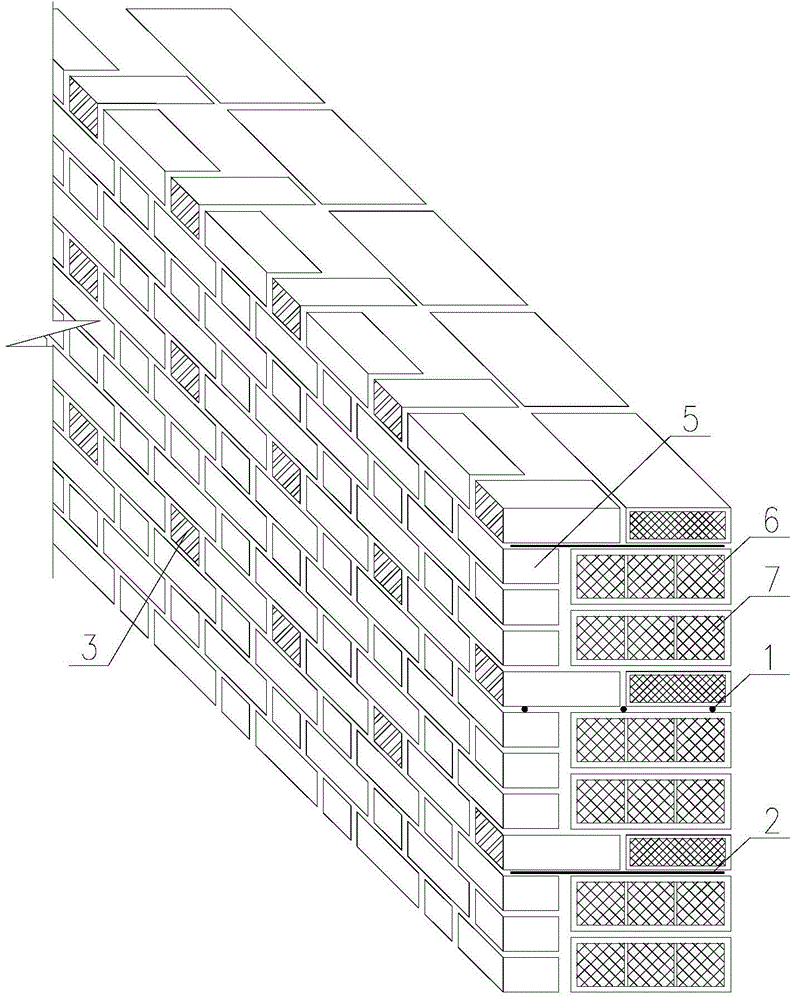

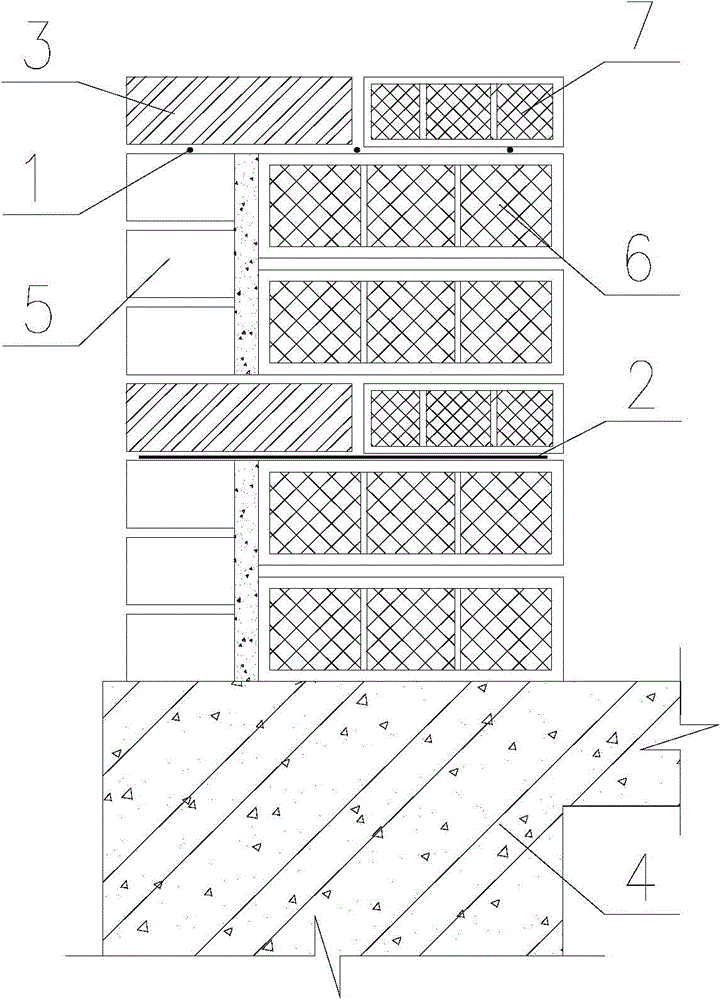

[0030] A clear-water composite wall built with shale decorative bricks and shale thermal insulation bricks, which is composed of several building units, and the building units include several leather shale decorative bricks 5, several leather shale thermal insulation bricks 6 and their masonry Mortar, shale decorative brick 5 is built with plum blossoms, shale thermal insulation brick 6 is built with full sleep, and the building unit is composed of four-skin shale decorative bricks, two-skin shale thermal insulation bricks and their masonry mortar , and every four skin bricks of shale decorative bricks is provided with a biting brick, and the biting brick is biting on the shale thermal insulation brick. The space between two adjacent building units is built with matching bricks 7 . Among them, Meihua Ding masonry, that is, masonry in one direction in the horizontal direction, and in the vertical direction with staggered joints in the middle. Sleeping is to lay the largest fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com