Rotary excavation pile machine hole bottom water injection variable tooth multifunctional rock drilling drill

A rotary pile driver, multi-functional technology, applied in the direction of drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve problems such as fracture, difficulty in taking out core, large consumption of drilling teeth, etc., to achieve safe and reliable structure, Easy to install and use, low wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

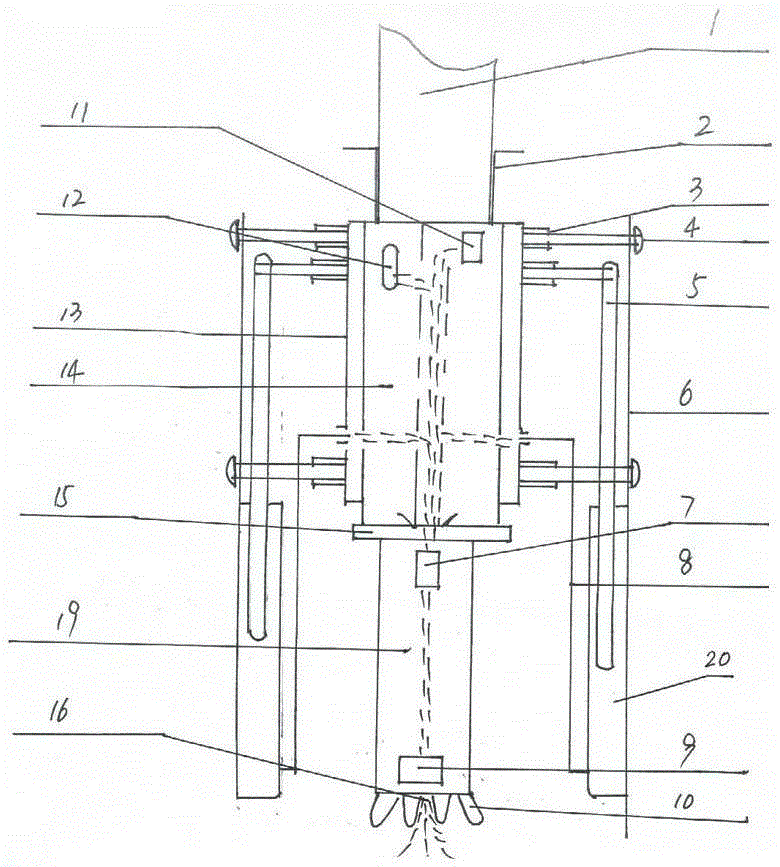

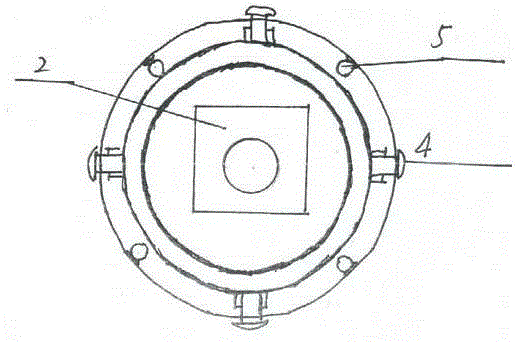

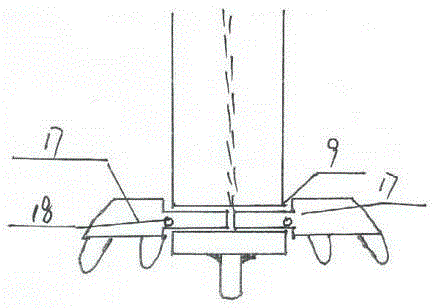

[0014] Such as figure 1 , 2 , 3, the upper end of the water-injection variable-tooth multifunctional rock drill of the present invention is inserted into the drill pipe socket 2 through the telescopic drill pipe 1 and connected, and the lower end of the drill pipe socket 2 is fixed on the upper end of the rotating water tank core body 14, and the rotating water tank core The body 14 is a steel cylinder with a middle hole, the lower end of the rotating water tank core body 14 is connected with a flange 15, and the upper end of the drill pipe 19 is connected to the rotating water tank core body 14 through the flange 15; the rotating water tank core body 14 A rotating water tank overcoat 13 is set on the outer circumference, and the rotating water tank overcoat 13 is a steel cylinder. Between the rotating water tank core 14 and the rotating water tank overcoat 13, there are lattice rings, bearings and skeleton oil seals. The rotating water tank core 14 can expand and contract wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com